Cooling Chiller

1. Bipolar compression

Adopting bipolar compression enhances the energy efficiency of the unit and broadens the capacity adjustment range of the unit

2. National patent

High-efficiency falling film evaporation technology

3. Invention patent

Flash evaporation tank technology

4. Self-developed

Remote intelligent control

5. Anti-surge technology

The combination of prevention, control and alarm makes the unit safer and more reliable

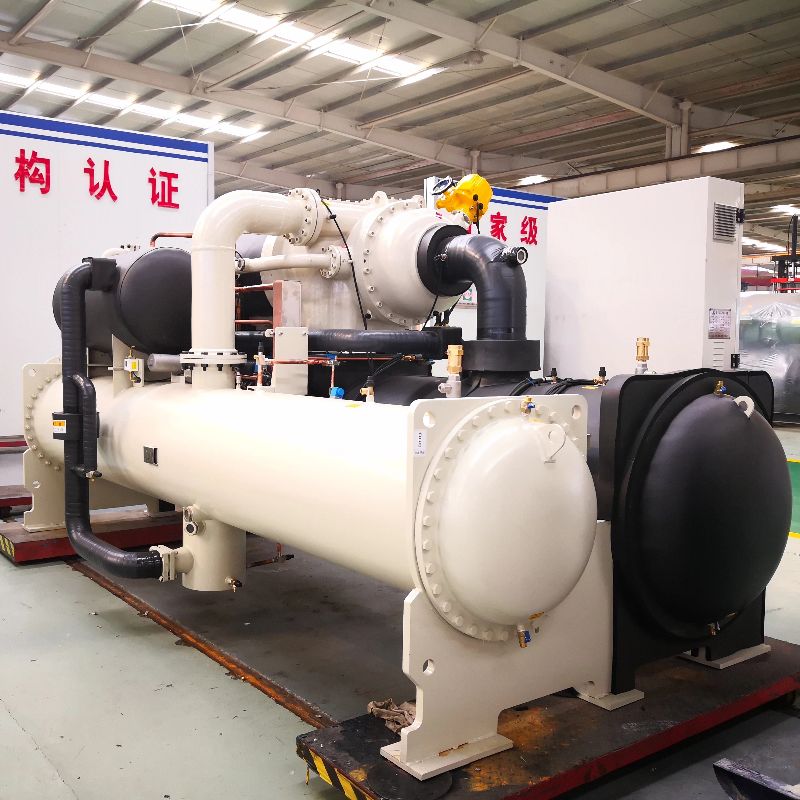

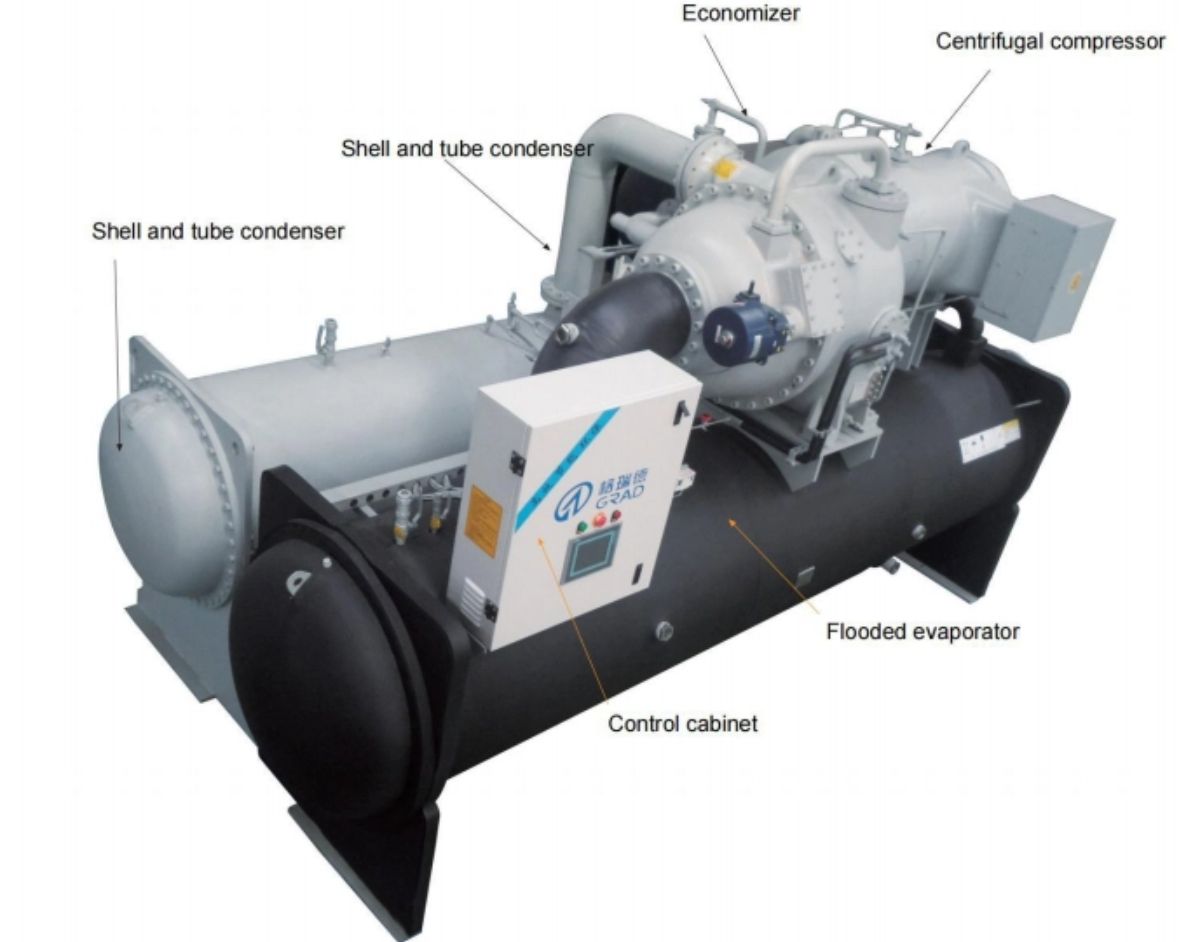

Water Cooled Centrifugal Chiller

Water Cooled Centrifugal Chiller is the use of electricity as a power source, freon refrigerant in the evaporator refrigerant evaporation, freon evaporation wet steam compressor compressed into high temperature and high pressure gas, the water cooling condenser is condensed into a liquid, the expansion valve throttling recirculation into the evaporator. Thus, the freezing water at 7 C -12 C is made for air conditioning at the end of air conditioning.

The GRAD ultra-high Efficiency falling film centrifugal unit is suitable for commercial real estate, residential real estate, industrial real estate and government public building customers. Through five core technologies including two-stage compression gas injection and enthalpy increase, high-efficiency falling film evaporation, flash tank, anti-pulsation and Internet of Things, it achieves a unique function of 15% improvement in unit energy efficiency and worry-free and cost-effective operation and maintenance. Solve the core problems of low energy efficiency of customer units, high operation and maintenance costs, and difficulties in fault diagnosis and maintenance.

Adopting the advanced domestic "two-stage compression" and "gas injection and enthalpy increase" technologies, compared with the single-stage compression centrifugal chiller, the COP can reach 6.34-6.65, and the energy efficiency can be improved by 5%-8%.

Features

★Production range: Single machine 350-2000RT

★Three-phase two-stage squirrel-cage induction motor

★Protection grade -IP54

★Y-△ start, direct start or soft start

★High-strength aluminum closed impeller

★High-efficiency two-stage compression and energy-saving design

★The high-speed shaft is made of high-strength alloy

★Under normal operation, the bearing life can reach up to 50,000 hours

Technical parameters table of centrifugal water cooled cold water chiller

Model | LC350A | LC400A | LC450A | LC500A | LC550A | LC600A | LC650A | LC700A | LC750A | LC800A | LC850A | LC900A | ||

Cooling capacity | RT | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | |

KW | 1231 | 1407 | 1583 | 1759 | 1934 | 2286 | 2462 | 2638 | 2814 | 3165 | 3341 | 3165 | ||

104Kca/h | 106 | 121 | 136 | 151 | 166 | 197 | 212 | 227 | 242 | 257 | 272 | 272 | ||

Electric motor | Power (kw) | 208 | 242 | 277 | 306 | 334 | 340 | 369 | 400 | 425 | 452 | 483 | 513 | |

Power supply | 380-3ph-50hz | 6000/10000V-3ph-50hz | ||||||||||||

Cooling mode | Refrigerant spray cooling | |||||||||||||

Performance factor COP (KW/KW) | 5.92 | 5.81 | 5.72 | 5.75 | 5.8 | 6.2 | 6.19 | 6.16 | 6.21 | 6.22 | 6.19 | 6.17 | ||

refrigerant | R134a | |||||||||||||

Evaporator | Cold water flow (m3/h) | 212 | 242 | 272 | 302 | 333 | 363 | 393 | 423 | 454 | 484 | 514 | 544 | |

Cold water press drop ( kpa) | 65 | 84 | 82 | 86 | 87 | 84 | 81 | 81 | 87 | 88 | 87 | 87 | ||

Number of pass cold water inlet and outlet | 2 | |||||||||||||

Temperature ( ℃) | 12/7 | |||||||||||||

Connection diameter (DN) | 200 | 250 | 300 | |||||||||||

Condenser | Cooling water flow (m3/h) | 265 | 302 | 340 | 378 | 416 | 454 | 491 | 529 | 567 | 605 | 643 | 681 | |

Cooling water press drop ( kpa) | 70 | 85 | 87 | 84 | 89 | 87 | 80 | 77 | 84 | 88 | 85 | 84 | ||

Number of pass cooling water inlet and outlet | 2 | |||||||||||||

Temperature ( ℃) | 30/35 | |||||||||||||

Connection diameter (DN) | 200 | 250 | 300 | |||||||||||

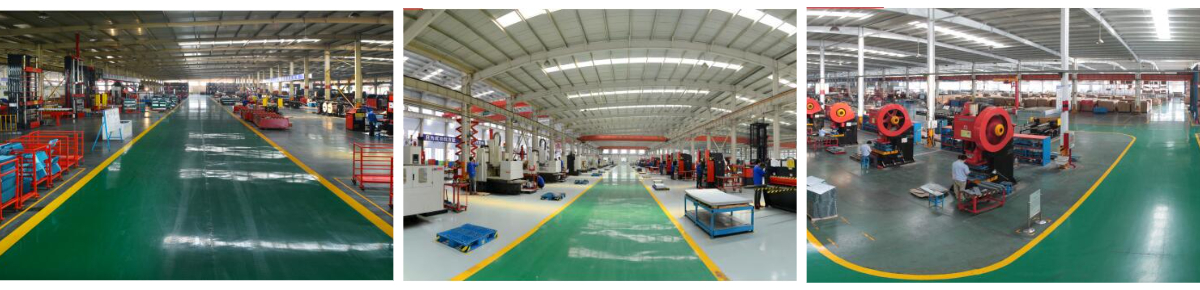

About us

GRAD Group devotes itself to be a central air conditioning customization expert around you and provides you a comprehensive energy solution, GRAD possesses national mechanical and electrical equipment installation Class I qualification and purification equipment installation Class II qualification. GRAD has the overall project contacting ability. It has contracted national class and provincial class technology research projects for many times. The accumulated patents for technolog achievements has passed 110 items. There are more than 300 senior engineers available for central air conditioning design and solution. The 700,000 ㎡ manufacturing base includes the whole central air conditioning series: from chiller to terminal products. The high efficient falling film centrifugal chiller maintains domestic leading position and the large fan wall air handling unit has filled domestic blank and been listed in the national torch plan. GRAD has the national class air conditioning testing center and has passed CNAS certification. The products quality can be well guaranteed. Some of projects gained China Construction Project Luban Prize and National High Quality Project. At the same time, GRAD has established more than 30 offices all over China, such as Beijing, Tianjin, Shenyang, Xi’an, Wuhan, Nanjing, etc. The sales, design, installation and after sales network has covered every corner of China. Moreover, its products have been exported to more than 100 countries.