Cassette Fan

Safe & Long-Lasting:

Each FCU undergoes pressure leak testing. Features include forged brass water inlets/outlets, rust-resistant condensation trays, fireproof materials, and a maintenance-free motor with up to 35,000 hours of operation.

High Efficiency:

Seamless red copper tubes combined with double-flanged aluminum fins ensure excellent heat transfer and enhanced cooling/heating performance.

Low Noise, High Airflow:

Wide volute and multi-blade centrifugal fan deliver strong airflow with minimal noise. Various fan-motor combinations suit different model needs.

Flexible Installation Options:

Choose from standard or extended water pans to suit space constraints or improve condensate and leakage collection.

Product Introduction – GRAD Cassette Fan

Cassette Fans are key terminals in central air conditioning systems, composed mainly of a centrifugal fan and heat exchanger. Widely used in hotels, restaurants, factories, exhibition halls, shopping malls, and office buildings, they provide efficient cooling, heating, and dehumidification, creating a fresh, quiet, and comfortable environment all year round.

Available in standard and high-efficiency models, the standard type meets national performance standards, while the high-efficiency version exceeds them by 20%, offering superior energy performance

Advantages

※Ultra-efficient

Energy efficiency exceeds the national standard by more than 15%

※Low noise

The noise is 1 to 2dB lower than the national standard

※Large air volume

It has a wide range of air volume, with a maximum air output of 3400m ³ /h

※More beautiful

With a national patent for appearance, the unit is lightweight and aesthetically pleasing as a whole

※High cost performance

A wide variety, customizable, and with an extremely high cost performance

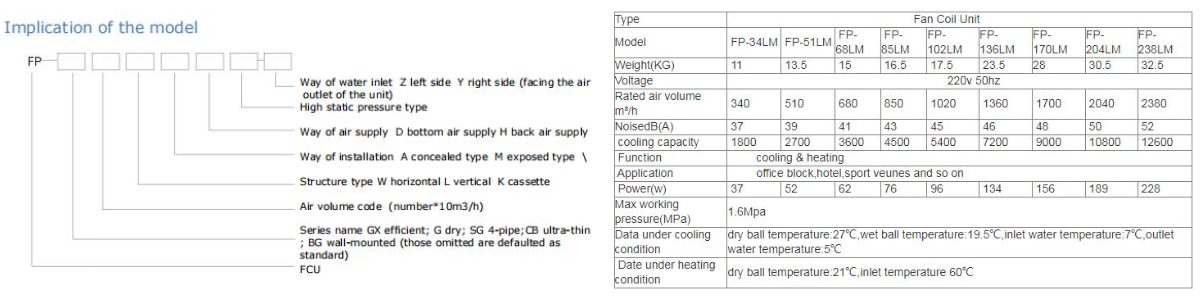

FP-KM Cassette type | |

This unit can be put into the ceiling ideally. Combined with the indoor decoration, there will be only air vent exposed on the ceiling. The air vent is elegant and it will cover no space. So it is easy to maintain and mend |

Parameter

Product Name | 2-pipe cassette chilled water FCU | |||||||||||||

Model:FPKM4-V/A | FP-34KM4-V/A | FP-51KM4-V/A | FP-68KM4-V/A | FP-80KM4-V/A | FP-85KM4-V/A | FP-102KM4-V/A | FP-136KM4-V/A | FP-170KM4-V/A | FP-204KM4-V/A | FP-238KM4-V/A | FP-289KM4-V/A | FP-340KM4-V/A | ||

Air Volume (m³/h) | H | 340 | 510 | 680 | 800 | 850 | 1020 | 1360 | 1700 | 2040 | 2380 | 2890 | 3400 | |

M | 280 | 390 | 520 | 580 | 640 | 790 | 1030 | 1290 | 1500 | 1800 | 2100 | 2600 | ||

L | 180 | 260 | 350 | 390 | 430 | 520 | 690 | 860 | 1030 | 1200 | 1600 | 1900 | ||

Cooling | Total capacity (Kw) | H | 2 | 2.7 | 3.7 | 4.2 | 4.5 | 5.6 | 7 | 9.1 | 10.8 | 12.6 | 15.3 | 17.6 |

M | 1.8 | 2.3 | 3.1 | 3.8 | 4.2 | 4.3 | 5.7 | 7.9 | 8.6 | 10 | 11.7 | 13.5 | ||

L | 1.6 | 1.8 | 2.6 | 2.8 | 3 | 3.6 | 4.5 | 6 | 6.8 | 8 | 9.3 | 9.9 | ||

Sensible capacity (Kw) | H | 1.5 | 1.9 | 2.6 | 2.9 | 3.5 | 3.9 | 5 | 6.4 | 7.7 | 9 | 11.5 | 14.8 | |

M | 1.3 | 1.7 | 2.0 | 2.6 | 3.2 | 3.3 | 4.3 | 5.9 | 6.5 | 7.5 | 8.4 | 11.1 | ||

L | 1.2 | 1.4 | 1.8 | 1.9 | 2.8 | 2.9 | 3.6 | 4.8 | 5.4 | 6.4 | 6.4 | 7.8 | ||

Water flow rate (l/h) | 345 | 470 | 640 | 720 | 780 | 970 | 1260 | 1710 | 1920 | 2160 | 2640 | 3027 | ||

Water pressure drop (Kpa) | 7 | 9 | 11 | 14 | 16 | 18 | 19 | 17 | 19 | 22 | 36 | 48 | ||

Heat | Heating Capacity (Kw) | H | 2.8 | 4.2 | 5.8 | 6.3 | 7 | 8.4 | 11.2 | 13.9 | 16.7 | 19.5 | 23.7 | 25.5 |

M | 2.5 | 3.4 | 4.5 | 5.5 | 6.3 | 6.5 | 8.5 | 12 | 12.6 | 15.6 | 17.5 | 18.6 | ||

L | 2 | 2.7 | 4 | 4.5 | 5 | 5.2 | 6.7 | 9 | 10.2 | 12 | 13.8 | 13 | ||

Power Supply | 220-240V/1PH/50HZ(or 60HZ) | |||||||||||||

Power Input (W) | 39 | 52 | 62 | 68 | 76 | 96 | 132 | 152 | 189 | 220 | 330 | 340 | ||

Sound pressure dB(A) | 37 | 39 | 41 | 42 | 43 | 45 | 46 | 47 | 50 | 52 | 57 | 65 | ||

Fan | Type | Centrifugal fan | ||||||||||||

Model | ∅315 | ∅315 | ∅315 | ∅315 | ∅380 | ∅380 | ∅380 | ∅476 | ∅476 | ∅476 | ∅530 | ∅530 | ||

Quantity | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

Motor | Type | 3-speed motor | ||||||||||||

Quantity | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

Coil | Coil rows | Nr. | 2 | |||||||||||

Max.Working pressure | Mpa | 1.6 | ||||||||||||

Tuber Diameter | inch | 3/8'' | ||||||||||||

Dimensions | Unit body | mm | 580x580x250 | 705x705x290 | 832x832x290 | 960x960x290 | ||||||||

Panel assembly | mm | 680x680x30 | 830x830x30 | 980x980x30 | 1140x1140x30 | |||||||||

Connection | Water inlet/outlet pipe | inch | ZG3/4'' | |||||||||||

Condensate discharge | inch | 26 | ||||||||||||

Weight (with feet,with casing) | KG | 20 | 25 | 34 | 52 | 50 | ||||||||

About us

Shandong GRAD Group Co.,Ltd. is established in 1993, located in Dezhou Shandong,covering an area of 700 thousand square meters, with more than 2500 employees. The total capital is 925 million RMB, and annual output value over 2.5 billion RMB. During 30 years' development, GRAD Group concentrates on the central air-conditioning and compound material products and show the world a high-technological

enterprise combining construction budget, technical consultation, products design, Manufacturing and debugging service. There are 10 series,over 130 kinds of products covering the whole central air-conditioning series and the compound materials seriesproducts. The high

standard workshop covering 350 thousand square meters.

GRAD sales network covers over 100 countries and regions like America, Australia Indonesia, Malaysia, UAE, Thailand, Nigeria etc and has established branch company in USA, and set up offices in Cambodia and Thailand to make overall layout of global market.

Before-sale services:

(1) Tell customers how to use our products and matters needing attention.

(2) Guide customers to choose the best and economic product, recover the investment within short time.

(3) Site inspection if you need.

In-Sale services:

(1)Quality control must be inspected strictly.

(2)In accordance with the agreements stipulated in the contract.

After-sale services:

(1) If the project needs our installation guidance, we can send our engineer and translator. We can also send customers installation video to teach them how to fix and operate with our product.

(2) Usually, our product warranty is 18 months after leaving factory or 12 months after installation. within this months, all parts broken will be responsible for our factory.

(3) Regular contact with customer, consult with the customer feedback, come true with the customer's two-way communication.