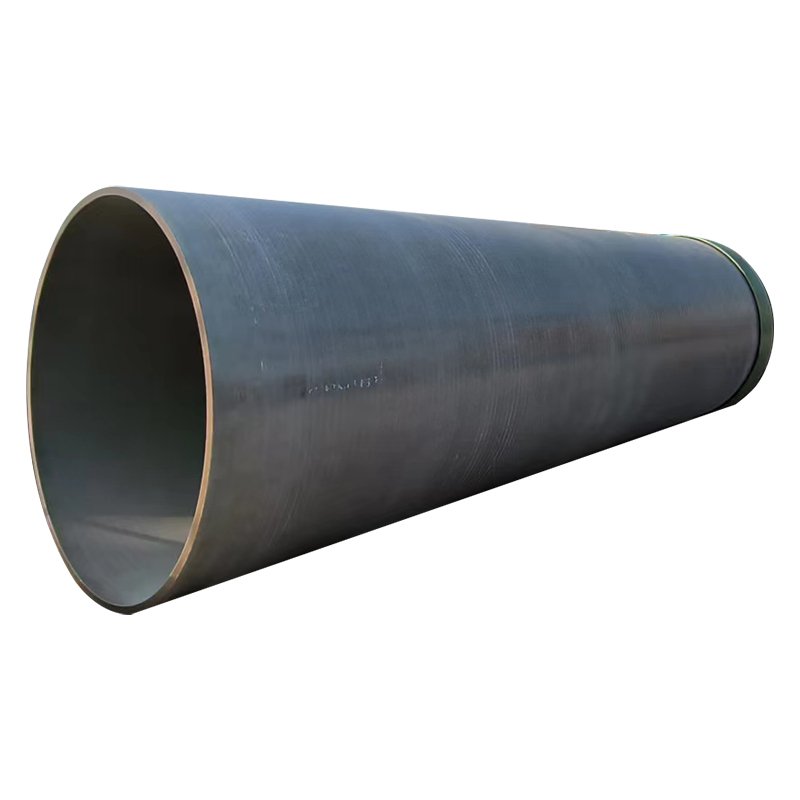

FRP Piping Systems

FRP Piping Systems are produced using the Continuous Filament Winding (CFW) process, ensuring high structural strength and excellent corrosion resistance—ideal for high-pressure applications.

FRP is lightweight, durable, easy to install, and resistant to environmental degradation. Its exceptional resistance to acidic conditions in water and sewage systems makes it especially suitable for long-term use.

GRP pipes are widely applied in potable water transport, sewage drainage, seawater systems, desalination plants, chemical and industrial waste pipelines, firefighting systems, cooling circuits, and agricultural irrigation.

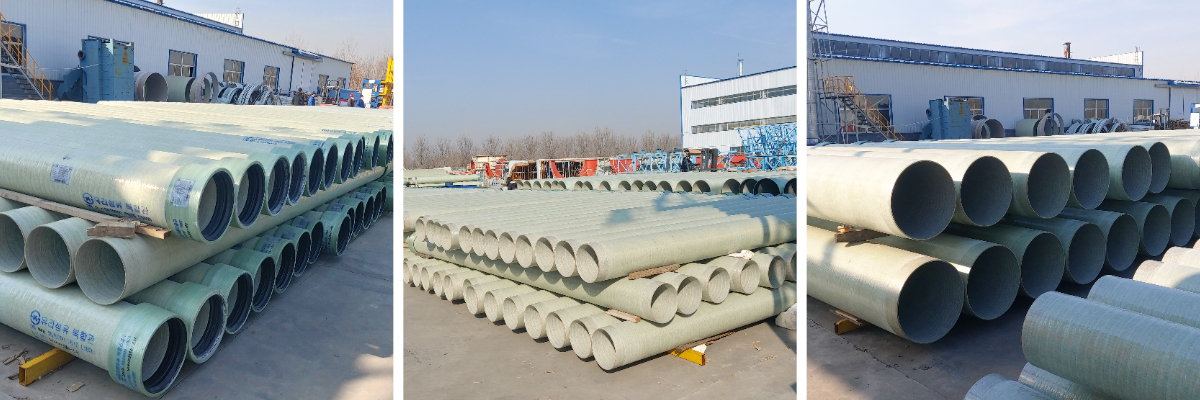

Pipes can be customized in diameter and length, making them especially efficient for installation in rehabilitation and lining projects, reducing labor and time costs.

FRP Piping Systems are manufactured using the process of Continuance Filament Winding (CFW). Our range of GRP pipe products offer structural strengths and corrosion resistance for optimum performance within high pressure applications. FRP is lightweight, extremely strong, easy to install, and resistant to deterioration.

Their resistance to water and sewage systems acidic environment is another advantage. Our GRP pipes are mainly used for transporting drinking water, sewage drainage and seawater, in addition to desalination water, chemical and industrial residues, fire-fighting systems, cooling systems and irrigation. GRP pipes can be manufactured in custom diameters and in any required length. This helps in easy installation especially in rehabilitation lining projects.

Fiberglass pipe has the advantages of light weight, high stiffness and low cost, each production length can reach 12 meters, fewer pipe joints, service life can reach more than 50 years, non-toxic and tasteless, and can directly transport drinking water. It can be fully applied to ship, municipal drainage, fire protection, water conservancy engineering, petrochemical, electric power and other industries of water transfer and circulating water projects.

Features

Corrosion Resistant

GRP pipes are designed for long effective service life without any type of protection such as lining, coating, cathodic protection or any other form of corrosion protection which is required for traditional material. This enables the GRP pipe end users to achieve low maintenance costs.

Light Weight and Long Pipe Sections

GRP pipe is one forth of DI pipe and one tenth of Concrete pipe by weight, reducing transport and handling equipments costs. The standard pipe length is 12 meters and can be 18 meters reducing number of joints thereby reducing the installation time and cost.

Extremely Smooth Pipe Interior Surface

GRP pipe have very smooth bore which reduces fluid flow frictional losses thereby reducing pumping cost. This also helps in minimizing slime build up reducing total operational costs.

Flexible & Leak Tight Coupling Joint

GRP flexible joint with elastomeric rubber rings allows pipe line for small change in direction reducing fittings use. The leak tight joint is designed to eliminate infiltration and exfiltration from the pipe line system. The joints can easily be assembled with pipes reducing the installation time.

Benefits

Long Service Life

Pipes are designed in compliance with the international standards to serve a minimum of 50 years. Operating and maintenance costs are negligibly small. .

Safe Connections

GRP pipe joints are designed with the flexible connection method, and the sealing is provided by couplings having full-face integrated elastomeric seal.

Surge Pressure Absorption

Additional pressure increases occurring due to surges are far less when compared with metal pipes. They are designed to absorb 40% of the surge pressure, without increasing the pressure class.

The following are some FRP pipeline projects with contract value more than ¥100 million of GRAD Group

About us

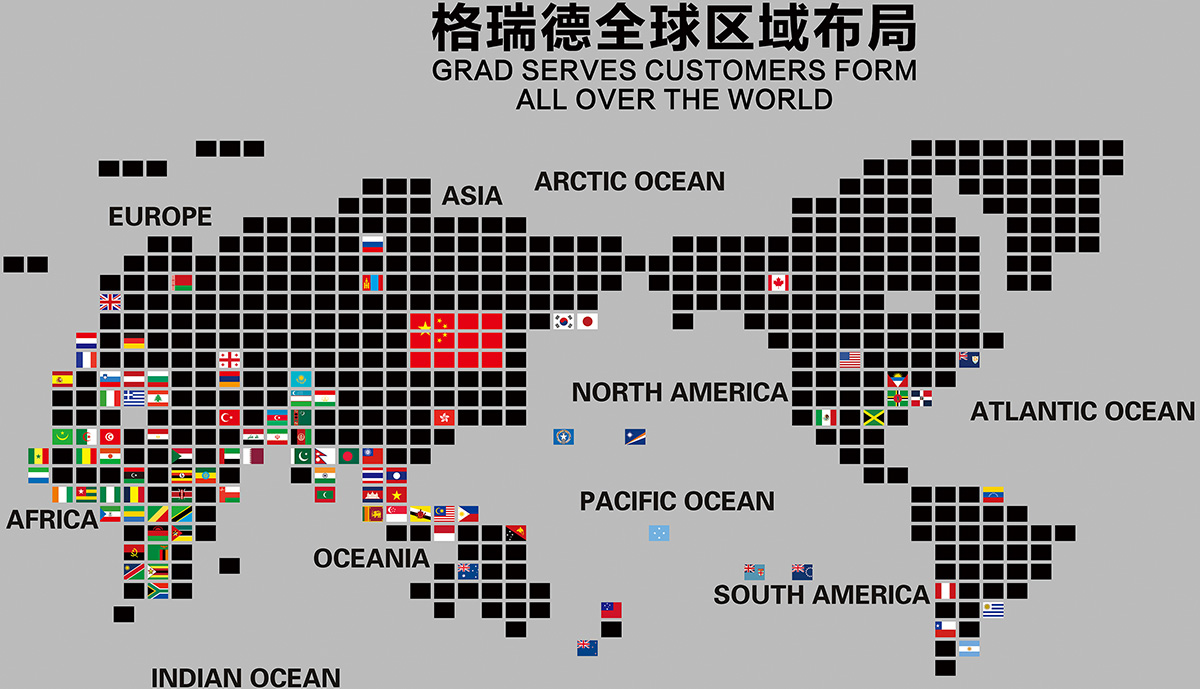

GRAD sales network covers over 100 countries and regions like America, Australia Indonesia, Malaysia, UAE, Thailand, Nigeria etc and has established branch company in USA, and set up offices in Cambodia and Thailand to make overall layout of global market.

Establised in 1993, GRAD Group covers an area of 1.15 million square meters and has more than 2,000 employees, with an annual output value of nearly 4 billion yuan. GRAD Group's main business: central air conditioning chiller and terminal products, FRP water tank, FRP winding pipe, FRP storage tank, wind turbine cabin cover, environmental protection equipment, and other more than 130 varieties. GRAD Group is the pillar enterprise of the “Dezhou Central Air-Conditioning City” named by the China Refrigeration and Air-Conditioning Industry Association. It ranks the top 10 among central air-conditioning enterprises in the country, and gets the first-class qualification for the installation of national electromechanical equipment and the second-class qualification for air purification engineering. GRAD Group can undertake central air conditioning engineering, purification engineering construction.

FAQ

Q1. Where is your loading port?

A: Qingdao/Shanghai/Tianjin, China or else port as for your request.

Q2. What's your company's main products?

A: Our company is specialized in central air-conditioning,ventilation and GRP Composite material products.

Q3. What’s your payment term.

A:T/T,30% deposit,70% before delivery or 100% Irrevocable L/C at sight.

Q4. What’s your warranty.

A:Warranty for 12 months from the date of shipment from the factory.