Water Storage Containers

The FRP combination water tank produced by GRAD meets the national standards.The water quality test and toxicology test were carried out by the provincial health and epidemic prevention station.The results showed that no toxic and banned compounds were found in the water quality.The results of 23 indicators including volatile matter were in accordance with GB/T17219-1998.Toxicology experiments:Animal experiments in FRP tank immersion showed no toxicity and no accumulation toxicity.

Product advantages

1.The installation is simple and convenient,and the process of secondary installation of the original insulated water tank is canceled , which saves the installation period.

2.Good thermal insulation effect.

3.Beautiful appearance,stable structure and good corrosion resistance.

Water Storage Tanks

The FRP water tank is assembled by FRP molded panel,sealing material,metal structure and supporting system.It can be spliced according to the needs of customers.The highest recommended is 3M or less,If it is more 3M high ,it needs special design.If the original water tank needs to be replaced,there is no need to improve the house,only there is a door to let the panels come in,and the adaptability is very strong,which brings great convenience to design and construction.

FRP water tank is light in weight,non-corrosive,non-leakage,good water quality,application range wide,long service life,good heat preservation performance,easy to clean and maintain,and highly applicable.It is an ideal product for public living water,fire fighting water and industrial water storage facilities.It has beautiful appearance,convenient construction,easy assembly and disassembly, and the structure of the panel adopts a cross shape.Compared with the steel water tank and the concrete water tank,it has its own characteristics and creativity.Although the initial investment of the combined water tank is higher than that of the traditional water tank,it has the advantages of small self-weight,convenient installation,easy maintenance and so on,so it is welcomed by the customers.

2000*1000mm,(Thickness included:4mm,5mm,6mm,7mm,8mm,9mm,10mm,12mm,)1000*1000mm,1000*500mm,500*500mm

(Thickness included 4mm,6mm,8mm,10-22mm;4mm water tank panel is specially designed as water tank cover).

SMC water tank panel standard (low configuration) | ||||||||

S.N. | Height mm | Thickness(mm) | Channel steel bottom frame | |||||

Bottom panel | Side panel 1 | Side panel 2 | Side panel 3 | Side panel 4 | Top panel | |||

1 | 1000 | 8 | 6 | 4 | 10# | |||

2 | 1500 | 8 | 6 | 6 | 4 | 10# | ||

3 | 2000 | 8 | 6 | 6 | 4 | 10# | ||

4 | 2500 | 12 | 12 | 8 | 6 | 4 | 10# | |

5 | 3000 | 12 | 12 | 6 | 6 | 4 | 10# | |

6 | 3500 | 16 | 16 | 12 | 8 | 6 | 4 | 10# |

7 | 4000 | 16 | 16 | 10 | 8 | 8 | 4 | 10# |

SMC water tank panel standard (higher configuration) | ||||||||

S.N. | Height mm | Thickness(mm) | Channel steel for | |||||

Bottom panel | Side panel 1 | Side panel 2 | Side panel 3 | Side panel 4 | Top panel | Bottom frame | ||

1 | 1000 | 10 | 10 | 5 | 10# | |||

2 | 1500 | 10 | 10 | 8 | 5 | 10# | ||

3 | 2000 | 12 | 10 | 8 | 5 | 10# | ||

4 | 2500 | 12 | 12 | 10 | 8 | 5 | 10# | |

5 | 3000 | 14 | 14 | 12 | 8 | 5 | 10# | |

6 | 3500 | 16 | 14 | 12 | 10 | 8 | 5 | 10# |

7 | 4000 | 18 | 18 | 14 | 12 | 10 | 4 | 10# |

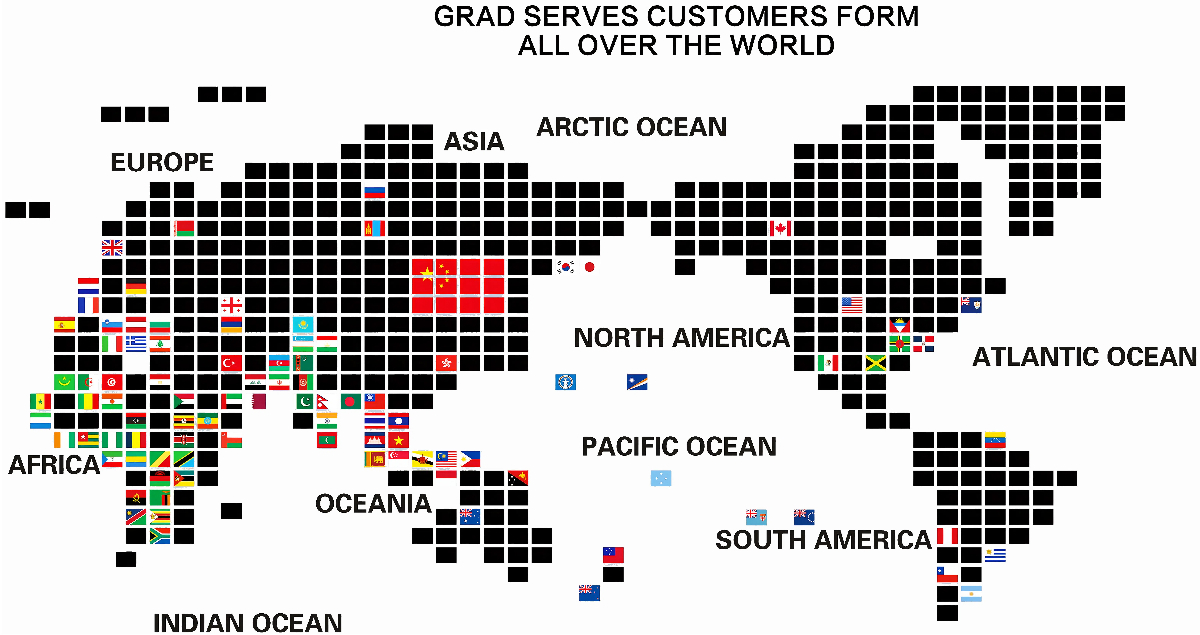

GRAD water tank had exported into Spain,Philippines, South Africa, Iran, Australia, Colombia, Lebanon, The united Arab emirates and so

on.And it gained good honor with its high quality and good price.

technique parameters:

Anti-longitudinal strength | >60 (Mpa) |

Bending strength | >120(Mpa) |

Bending flexibility module | >10(Gpa) |

Barcol hardness | >60(HBa) |

Water absorption | <1.0% |

Fiberglass content | ≥27% |

Size deviation | 2000±6mm; 1000±3mm |

About us

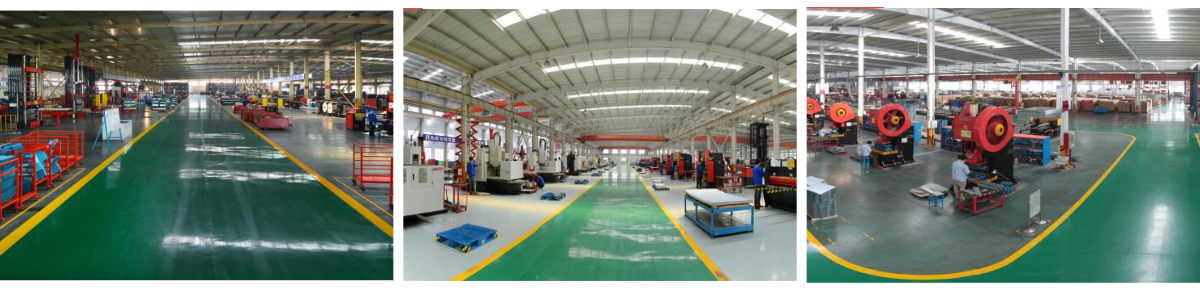

GRAD Group devotes itself to be a central air conditioning customization expert around you and provides you a comprehensive energy solution, GRAD possesses national mechanical and electrical equipment installation Class I qualification and purification equipment installation Class II qualification. GRAD has the overall project contacting ability. It has contracted national class and provincial class technology research projects for many times. The accumulated patents for technolog achievements has passed 110 items. There are more than 300 senior engineers available for central air conditioning design and solution. The 700,000 ㎡ manufacturing base includes the whole central air conditioning series: from chiller to terminal products. The high efficient falling film centrifugal chiller maintains domestic leading position and the large fan wall air handling unit has filled domestic blank and been listed in the national torch plan. GRAD has the national class air conditioning testing center and has passed CNAS certification. The products quality can be well guaranteed. Some of projects gained China Construction Project Luban Prize and National High Quality Project. At the same time, GRAD has established more than 30 offices all over China, such as Beijing, Tianjin, Shenyang, Xi’an, Wuhan, Nanjing, etc. The sales, design, installation and after sales network has covered every corner of China. Moreover, its products have been exported to more than 100 countries.

1.Water tank panel usually packed with plywood pallet

2.Accessories usually loaded plywood boxes,in order to avoid lost

3.Delivery: 20 days after deposit is confirmed.