Air Handler Unit

1. High efficiency and energy saving

According to customer requirements, variable frequency compressors can be adopted, which have high energy efficiency. PLC programming supports different communication protocols and multiple modes to choose from

2. Simple and easy operation

The control system is advanced. The hand controller can be installed in the control room and supports remote operation

3. Safe and reliable

It features functions such as over-temperature protection for compressor exhaust, overload and overheating protection, high and low pressure protection, over-temperature protection for electric heating, and password protection

4. Complete range of varieties

Cold (hot) air type, constant temperature and humidity type, etc. can be selected as needed to achieve year-round cooling

Air Handler Unit

Overview

GRAD Air Handler Unit covers vertical (air volume from 2000 ~ 60000m3 /h), horizontal (wind increased from 2000 ~ 60000m3/h), and ceiling-type (air volume from 1000 ~ 16000m3/h) three series of air-handling unit to meet customers’ need of cooling, heating, humidification, dehumidification and so on. It is widely applied in hotels, theaters, shopping malls, office buildings and a variety of places requires comfortable environment. It also can be used in electronics, chemical, medical, pharmaceutical, cigarettes, food, light engineering and other industrial buildings.

↘Frame structure

The unit adopts aluminum alloy frame structure or metal frame structure, it has the following features

A: Good performance in mechanical strength, light in weight, corrosion resistance, beautiful shape and accurate size.

B: Flexible assemblage, very convenient to install, remove and maintenance. Also, it has longer service life than steel structure.

↘Fan, motorl

A unit adopts centrifugal fan with both air inlet. The fan runs smoothly in the rigorous static and dynamic balance ̀ test.

B: With ball bearings sealed, and functions of pre-lubricating, self-aligning, self-locking, automatic thrust, etc., the fan is maintenance-free in normal use.

C: Fans of a small model unit are driven directly by external sub-motor, no belt, and easy to maintain.

↘Filter

Unit filter is coarse plate. Filter material is cleanable convex Nylon net.

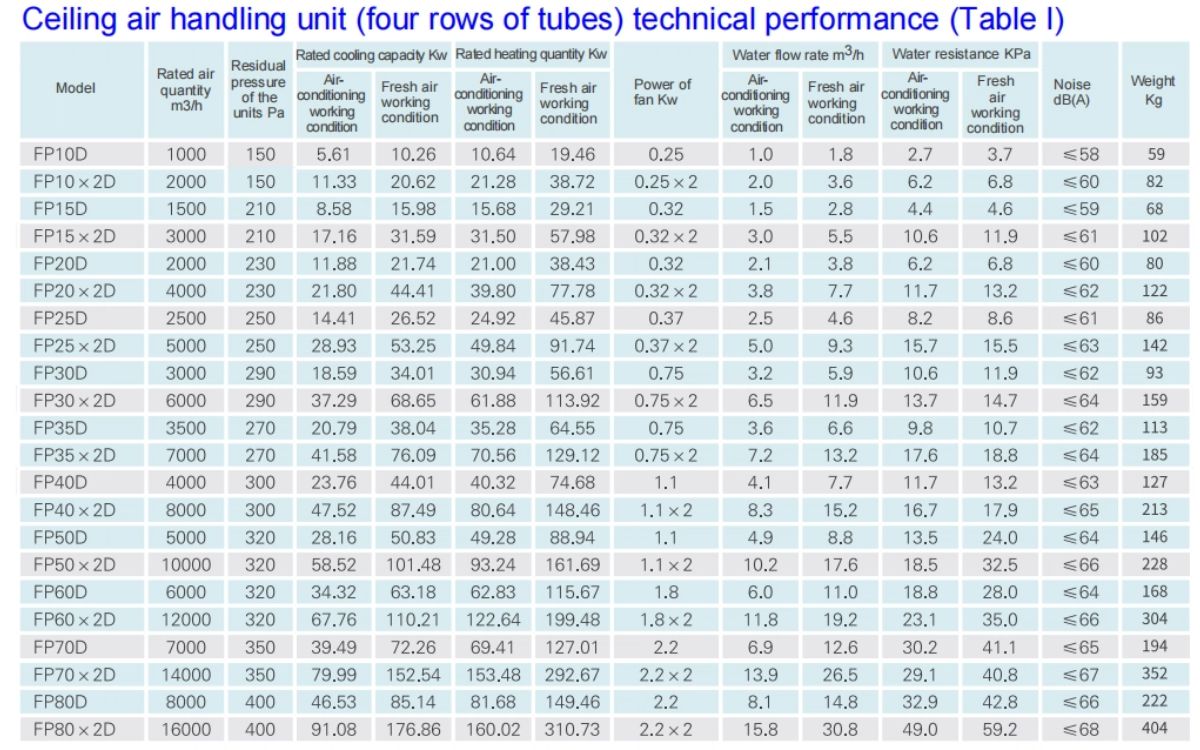

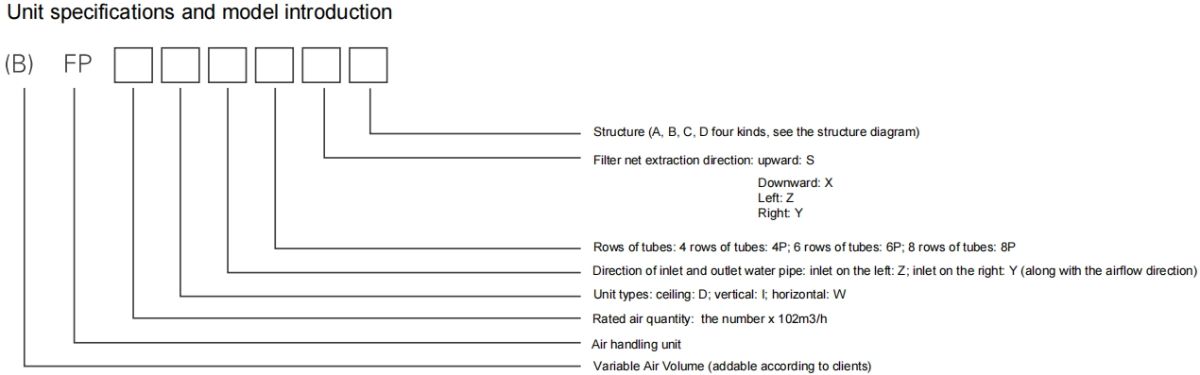

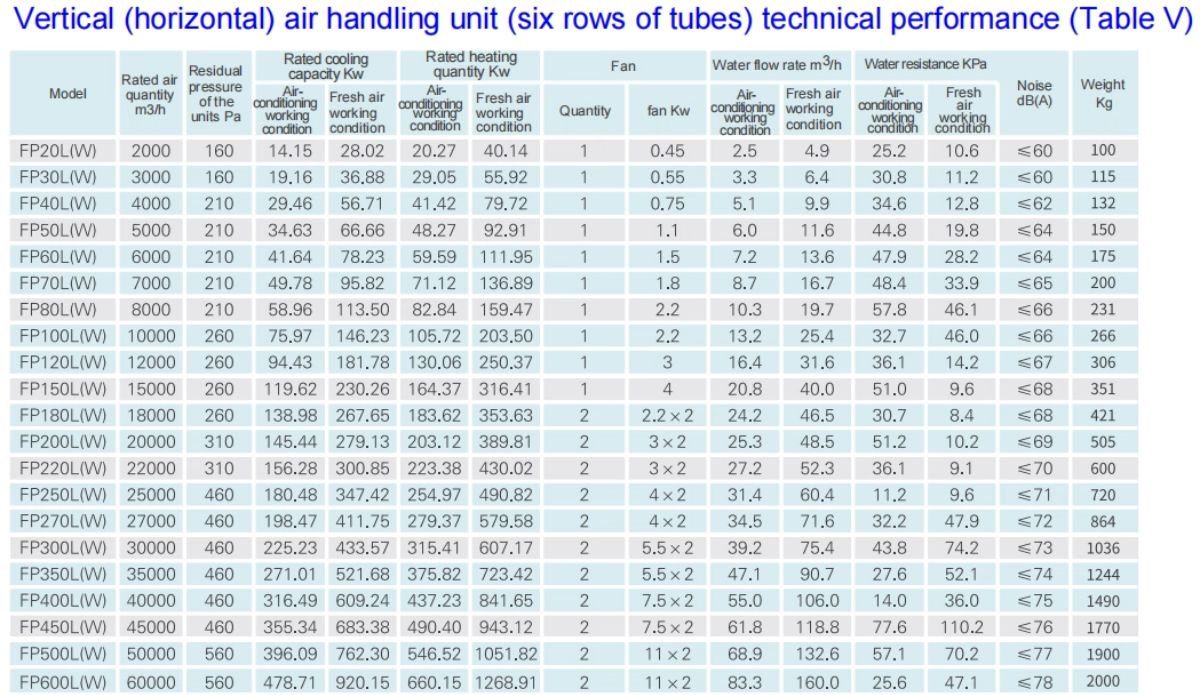

Air handling unit performance (Table I ~ Table VI)

1. Air-conditioning working condition means that the dry bulb temperature of intake air is 27℃, wet bulb 19.5℃ while cooling, and dry bulb 21℃ while heating.

2. Fresh air working conditions (l00% fresh air) means when cooling, dry bulb temperature of intake air is 350℃, wet bulb temperature 28℃, dry bulb temperature of intake air -5℃ while heating.

3. Cold water temperature: supply water is 7℃, back water is 12℃. Hot water supply temperature is 60℃.

4. The motor power values from table I to tableVI correspond with its different residual pressure. The residual pressure is flexible, which can be decided by our customers according to needs.

5. The noise values from table I to table VI are tested in the muffling section 1m (GB/T9068) away from each surface of the units.

Please be sure of the size, model, cool and heat quantity and left/right form in selecting air handling unit. Electrical controller is not part of the unit. However, the electric protector and air quantity speed regulation (including variable frequency controller and thyristor controller) is addable according to clients’ needs. Neither is inlet and outlet air quantity valve part of the unit. Please inform us before ordering if you need it. Our products are not limited to our routine units. According to clients’ special needs, unit can be equipped with additional electrical (auxiliary) heater, humidifier (steam humidifier, wet membrane humidifier, high-pressure spray humidifier and electrode humidifier), silencerand so on. Our company follows the principle of constantly improving our products. Please kindly excuse us if we do not inform you in time about changes or improvement of product performance, specifications, and materials, and keep in touch with us to obtain the latest information.

About us

Shandong GRAD Group is a large modern enterprise with over two decades history. Our business started in 1993, with staff of over 2200, we are focus on R&D, production, marketing, installation and maintenance for central air conditioning system and G R P composite material products. We are committed to providing customers with one-stop central air-conditioning and FRP composite material product solutions.

For central air conditioning products, we have production facility covering 450000 sqm, we can offer products for the whole system including chillers, heat pumps, cooling towers, A H U s, F C U s and ventilation products. To better participate international project, we have C T I, C E, A H R I certificates to guarantee our products quality.

For G R P composite material products, we have production facility covering 700000 sqm. With its feature of light weight, high strength, anti-corrosion and long service life, the G R P products are ideal replacement for steel products. We can offer process like vacuum injection, G R P winding, S M C mould pressing, molding pultrusion and hand paste. Based on different process, we can offer clients customized products.

GRAD international business starts in 2009, now its products have been exported to 100 countries and regions.

Q1. Where is your loading port?

A: Qingdao/Shanghai/Tianjin, China or else port as for your request.

Q2. What's your company's main products?

A: Our company is specialized in central air-conditioning,ventilation and GRP Composite material products.

Q3. What’s your payment term.

A:T/T,30% deposit,70% before delivery or 100% Irrevocable L/C at sight.

Q4. What’s your Warranty.

A:Warranty for 12 months from the date of shipment from the factory.