Recirculating Water Chiller

1.The heat exchange efficiency is increased by 10%, the refrigerant charge is reduced by 27%, and the volume of the unit can be effectively reduced by more than 20%

2. Remote intelligent services

3. Applicable to multiple scenarios and working conditions

4. Low operation and maintenance costs

5. The falling film evaporation technology has been granted a national patent

Recirculating Water Chiller

Core technology

Through four core technologies - real-time flow control, efficient falling film evaporation, efficient oil separation and return technology, and Internet of Things remote intelligent services - the unit's energy efficiency has been increased by 10%, and its operation and maintenance are worry-free and cost-effective. The unit is more efficient, reliable and stable. The remote intelligent service center can monitor in real time and handle faults quickly online, providing customers with a more considerate and prompt product experience and after-sales service.

Save energy efficiency

The national patented falling film evaporation technology uses high-efficiency falling film heat exchange tubes. The refrigerant is evenly drizzled onto the heat exchange tube array through the liquid distributor and forms a film on the surface of the heat exchange tubes, allowing the refrigerant to fully contact the heat exchange tubes. The heat exchange efficiency is increased by more than 10% compared with the traditional flooded evaporator, the refrigerant charge is reduced by 27%, and the oil return effect is improved. It can effectively reduce the volume of the unit by more than 20%, providing a larger space for the layout of the machine room. This technology has been successfully patented: Falling film Evaporator for Refrigeration and Air Conditioning, patent number: ZL201520313780.5

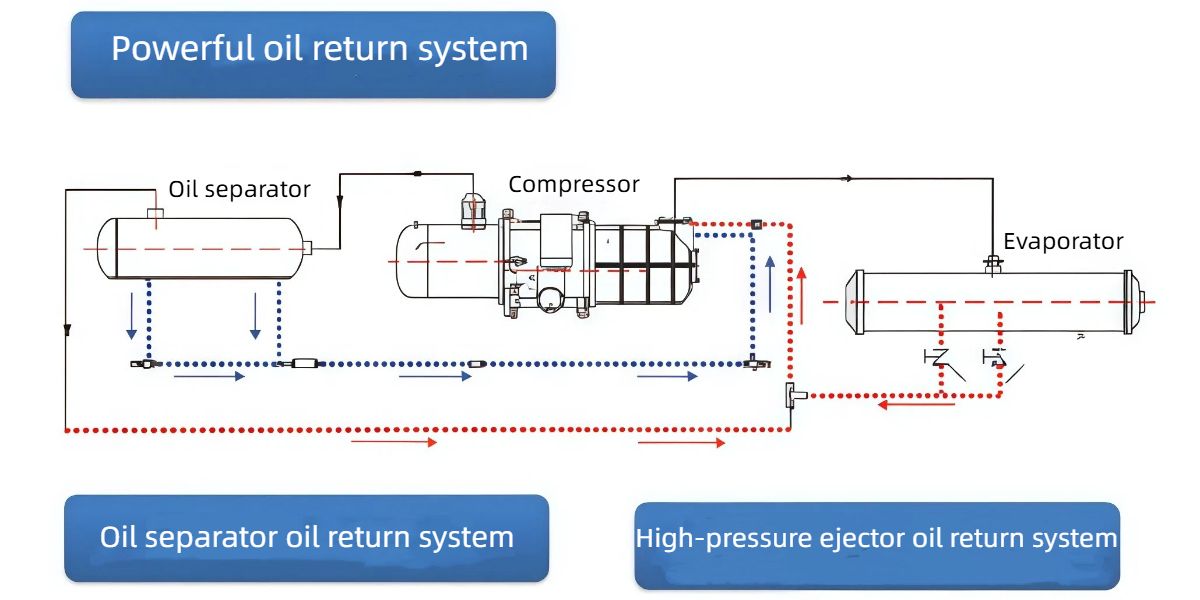

Stable and reliable

The GRAD national patent external high-efficiency oil separation technology, through the high-efficiency external secondary oil separator composed of the shell, end head, intake pipe assembly, baffle, oil and gas filter screen assembly, outlet assembly, return oil port and sight glass, adopts the three-stage separation principle of oil and gas collision deflection separation, gravity sedimentation separation and filtration separation to separate the refrigerant gas and the lubricating oil in the gas Its structure is simple, easy to manufacture, with high separation efficiency, stable and reliable operation of the unit, and no risk of liquid carrying in the suction.

Application scope

Comfort air conditioning systems: large supermarkets or commercial complexes, hotels, shopping malls, office buildings, exhibition halls, airports, stadiums, etc.

Process air conditioning systems: electronics, biology, light textile, chemical engineering, metallurgy, pharmaceuticals, power, machinery, etc.

1.GRAD has the National Laboratory of Air Conditioning Products recognized by CNAS, which is used for the design, development and experimental research of water-cooled chiller and the factory test of products.

2.Strict factory product quality control, so that users can buy at ease, with satisfaction.

3.GRAD screw type water cooled chiller series products ware tested by the national air conditioning quality testing center, the technical performance indicators are higher than GB/T184330.1-2007"Vapor compression cycle cold water (heat pump) unit Part 1: Industrial or commercial and similar uses of cold water (heat pump) units "standard, product quality is stable, reliable operation, has been praised by the majority of users at home and abroad.

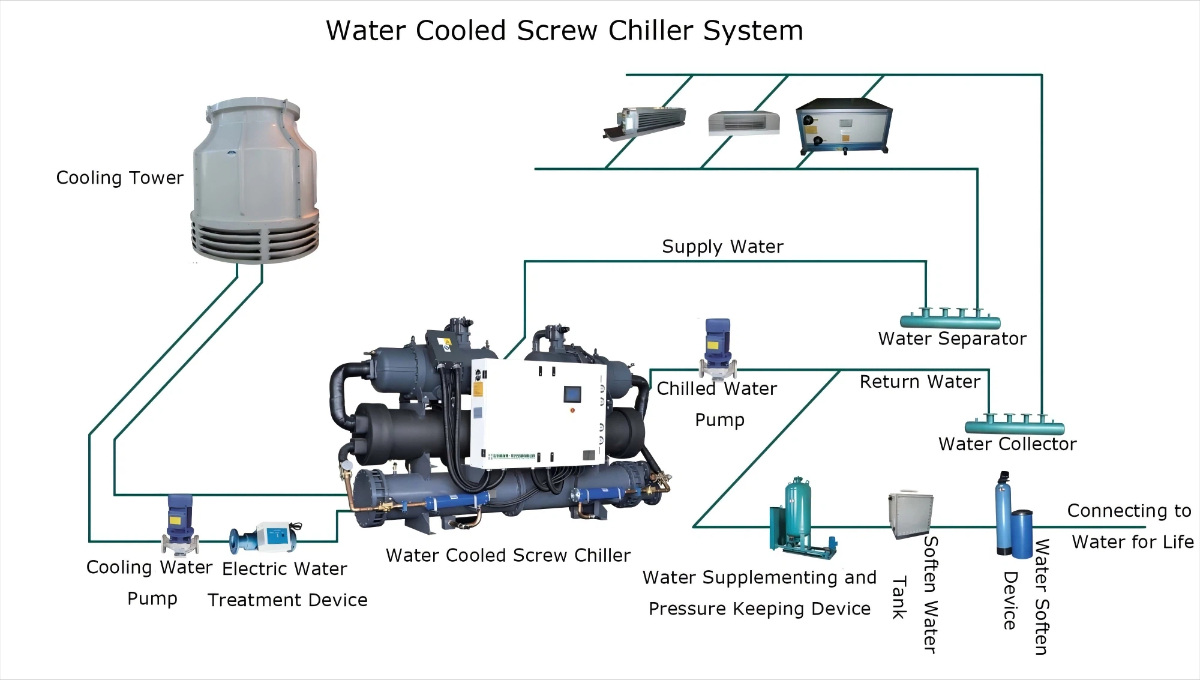

Water -Cooled Central Air Conditioning System Customized Service

We offer professional water-cooled central air conditioning customized system services. We can conduct preliminary system design based on the specific needs of each project, ensuring the integrity and efficiency of the entire water-cooling system.

For further information about our customized central air conditioning water-cooled system services, please contact our professional team. We are dedicated to providing you with the highest quality service.

Manufacturer:Shandong GRAD Group Co.,Ltd.

Established Time:1993

Covers an area of:700,000sqm

Main products:Central air conditioners,ventilators ,GRP Composite material products,Environment protection products

Employment : 2500+ employees

Registered capital: ¥ 100 million

Equipment price : ¥370 million

Total capital :¥ 925 million

Annual output value: ¥over 3 billion

Design team:300+

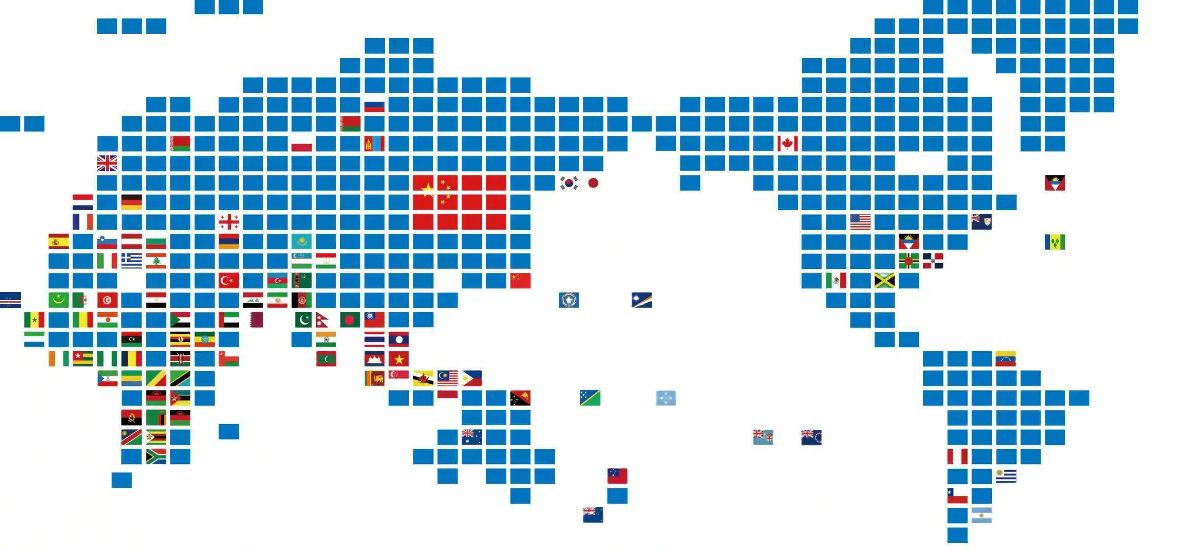

Overseas offices:

1. Thailand and Cambodia offices

2. USA branch company

GRAD international business starts in 2009, now its products have been exported to 100 countries and regions.

GRAD, as a flagship enterprise in central air conditioner and G R P composite material products industry, is dedicated to be a one-stop supplier for global purchasing agents.