Aquatic Chiller

Test ability, technical level

1.GRAD has the National Laboratory of Air Conditioning Products recognized by CNAS, which is used for the design, development and experimental research of water-cooled chiller and the factory test of products.

2.Strict factory product quality control, so that users can buy at ease, with satisfaction.

3.GRAD screw type water cooled chiller series products ware tested by the national air conditioning quality testing center, the technical performance indicators are higher than GB/T184330.1-2007"Vapor compression cycle cold water (heat pump) unit Part 1: Industrial or commercial and similar uses of cold water (heat pump) units "standard, product quality is stable, reliable operation, has been praised by the majority of users at home and abroad.

Aquatic Chiller

GRAD Water-Cooled Screw Chiller

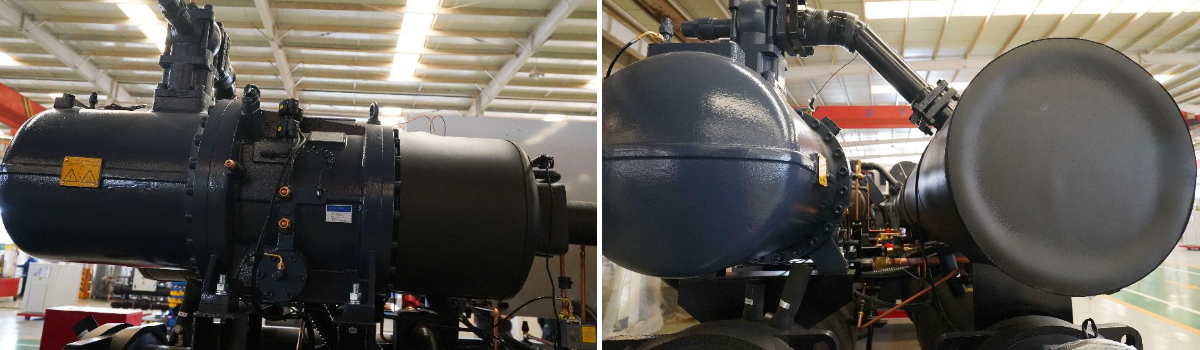

Featuring semi-closed twin-screw compressors, our chillers offer single or multi-circuit designs for flexible cooling solutions. The integrated control system, housed in a centralized cabinet, provides real-time monitoring via a computer interface.

Fully factory-assembled and tested, these units ensure reliable performance for commercial and industrial applications, including:

Shopping malls & office buildings

Hotels & hospitals

Factories & commercial facilities

Compliant with GB/T18430.1-2007, GRAD chillers meet stringent standards for efficiency, safety, and durability in vapor compression cooling systems.

Product application scope

Screw water cooled chiller is widely used in hotels, shopping malls, office buidings, exhibiion halls, airports, stadiums and other public faclites comfort central air condtioning system,and it can meet the process air condtioning system different requirements of electronic, pharmaceutical, biological, textile, chemical, metallurgy, pharmaceutical, electic power, machinery and otherindustries.

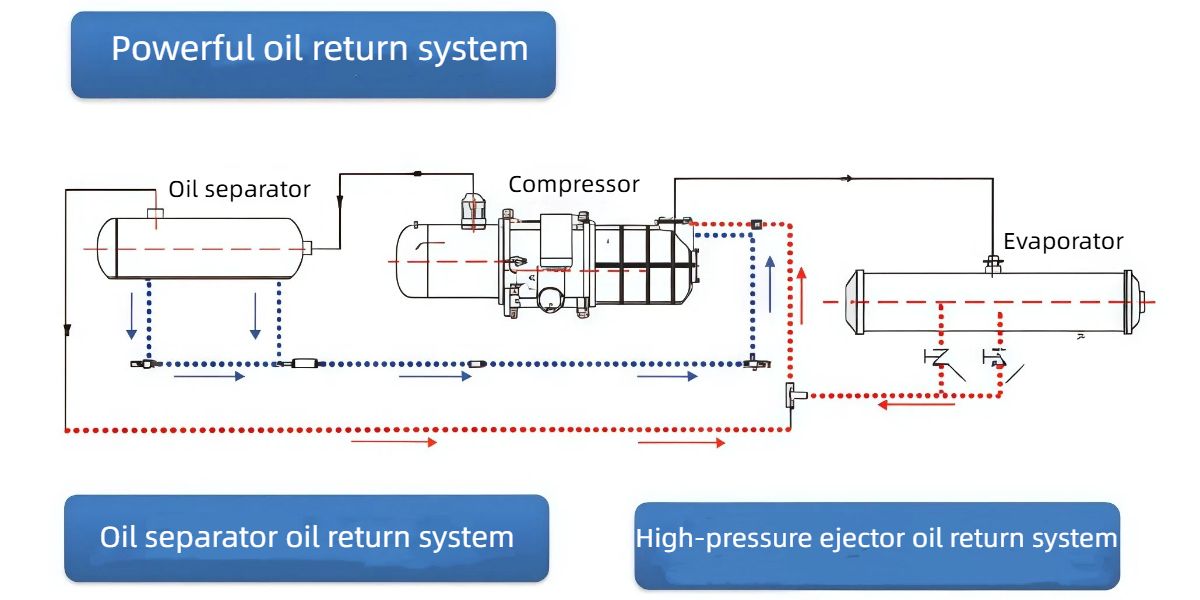

Core Technology

By integrating four breakthrough technologies—real-time flow control, high-efficiency falling film evaporation, advanced oil separation & return, and IoT remote monitoring—the chiller achieves 10% higher energy efficiency while ensuring low-maintenance, cost-effective operation. The remote intelligent service center enables real-time performance tracking and rapid online fault resolution, delivering superior reliability and seamless after-sales support.

Energy Efficiency

Featuring patented falling film evaporation technology, the chiller utilizes a precision liquid distributor to evenly coat refrigerant over high-efficiency heat exchange tubes, forming a thin film for maximum heat transfer. Compared to traditional flooded evaporators, this innovation delivers:

✔ 10%+ higher heat exchange efficiency

✔ 27% reduction in refrigerant charge

✔ Improved oil return performance

✔ 20%+ smaller unit footprint (optimizing machine room space)

Patent: Falling Film Evaporator for Refrigeration and Air Conditioning (No. ZL201520313780.5)

Reliability & Stability

The GRAD-patented external oil separation system employs a three-stage separation process (deflection, gravity sedimentation, and filtration) to efficiently remove lubricating oil from refrigerant gas. Key benefits:

✔ High separation efficiency

✔ Compact, durable design

✔ Stable operation with no liquid carryover risk

✔ Easy maintenance with visible oil return monitoring

About us

Establised in 1993, GRAD Group covers an area of 1.15 million square meters and has more than 2,000 employees, with an annual output value of nearly 4 billion yuan. GRAD Group's main business: central air conditioning chiller and terminal products, FRP water tank, FRP winding pipe, FRP storage tank, wind turbine cabin cover, environmental protection equipment, and other more than 130 varieties. GRAD Group is the pillar enterprise of the “Dezhou Central Air-Conditioning City” named by the China Refrigeration and Air-Conditioning Industry Association. It ranks the top 10 among central air-conditioning enterprises in the country, and gets the first-class qualification for the installation of national electromechanical equipment and the second-class qualification for air purification engineering. GRAD Group can undertake central air conditioning engineering, purification engineering construction.