Air Handler

1. High efficiency and energy saving

According to customer requirements, variable frequency compressors can be adopted, which have high energy efficiency. PLC programming supports different communication protocols and multiple modes to choose from

2. Simple and easy operation

The control system is advanced. The hand controller can be installed in the control room and supports remote operation

3. Safe and reliable

It features functions such as over-temperature protection for compressor exhaust, overload and overheating protection, high and low pressure protection, over-temperature protection for electric heating, and password protection

4. Complete range of varieties

Cold (hot) air type, constant temperature and humidity type, etc. can be selected as needed to achieve year-round cooling

Air Handler

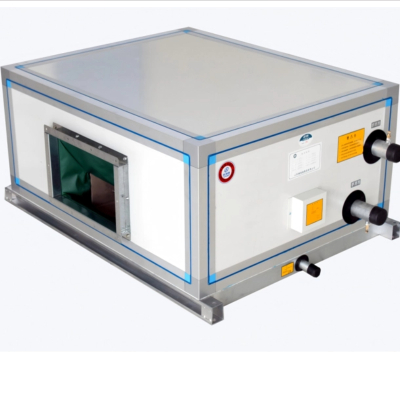

Overview

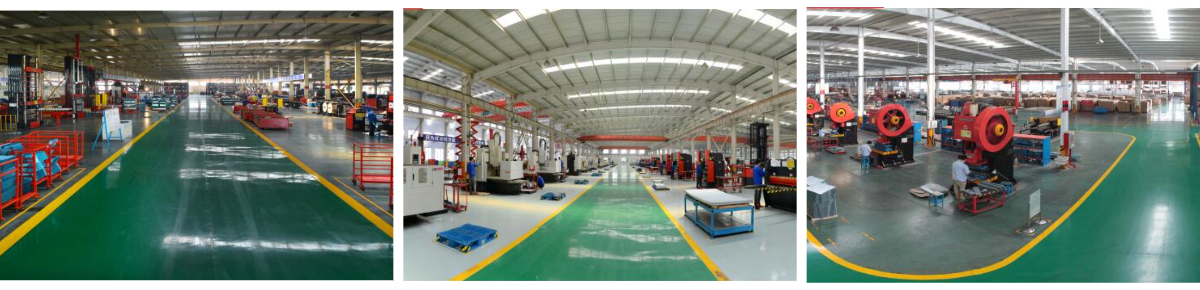

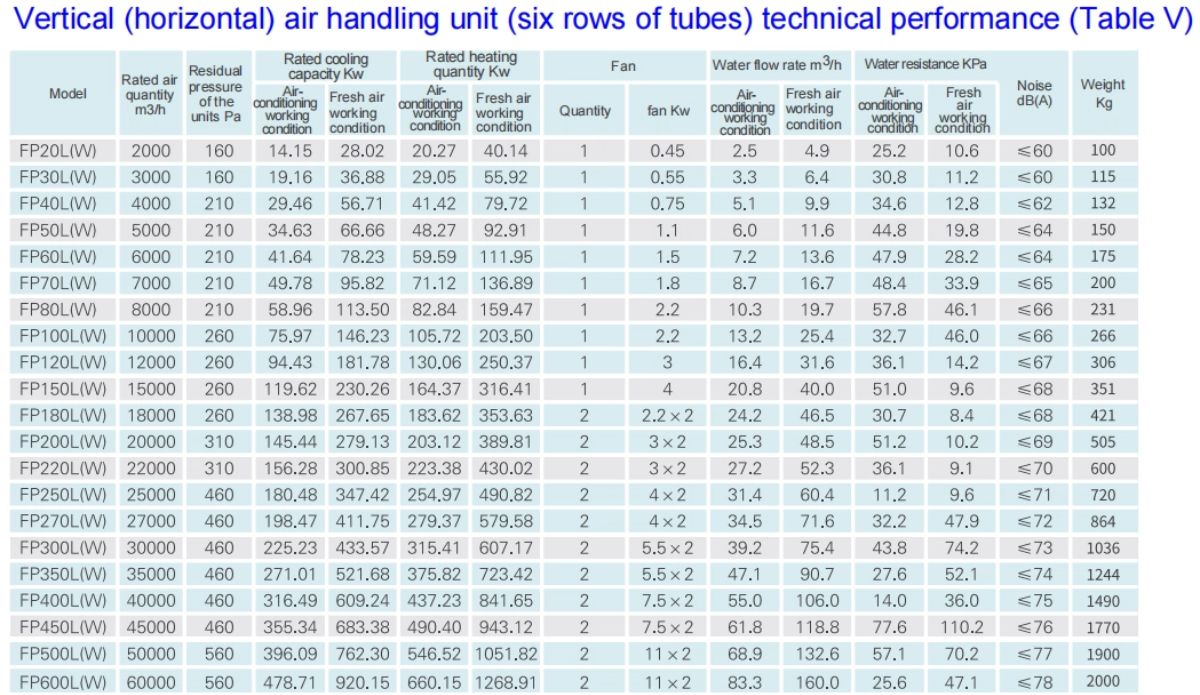

GRAD Air Handler covers vertical (air volume from 2000 ~ 60000m3 /h), horizontal (wind increased from 2000 ~ 60000m3/h), and ceiling-type (air volume from 1000 ~ 16000m3/h) three series of air-handling unit to meet customers’ need of cooling, heating, humidification, dehumidification and so on. It is widely applied in hotels, theaters, shopping malls, office buildings and a variety of places requires comfortable environment. It also can be used in electronics, chemical, medical, pharmaceutical, cigarettes, food, light engineering and other industrial buildings.

↘Panel structure

A: The panel is formed by two layers of colored steel plates. Filler between the layers is high-density polyurethane or polystyrene, which has a better performance in thermal isolation than other materials like glass wool. o ̀ thermal bridge will be produced while working in all weather or working conditions.

B: panels are fixed in a special way, with sealing material to strengthen its thermal and air resistance. This structure has the best performance in thermal isolation, noise reduction and intensity, so it can be used in places require high quality of air.

↘Cooler

The selected parameters of surface air cooler are designed by CAD/coi1 software. The standard cooler normally has copper pipes of φ6. It is tightened by an overall rise up of brass strung by corrugated aluminum fin tubes. Staggered copper pipes have good heat transfer performance, low airflow resistance and superior corrosion resistance, ensuring the cooler has a higher heat transfer coefficient and a longer life.

↘Fan, motorl

A: unit adopts centrifugal fan with both air inlet. The fan runs smoothly in the rigorous static and dynamic balance ̀ test.

B: With ball bearings sealed, and functions of pre-lubricating, self-aligning, self-locking, automatic thrust, etc., the fan is maintenance-free in normal use.

C: Fans of a small model unit are driven directly by external sub-motor, no belt, and easy to maintain.

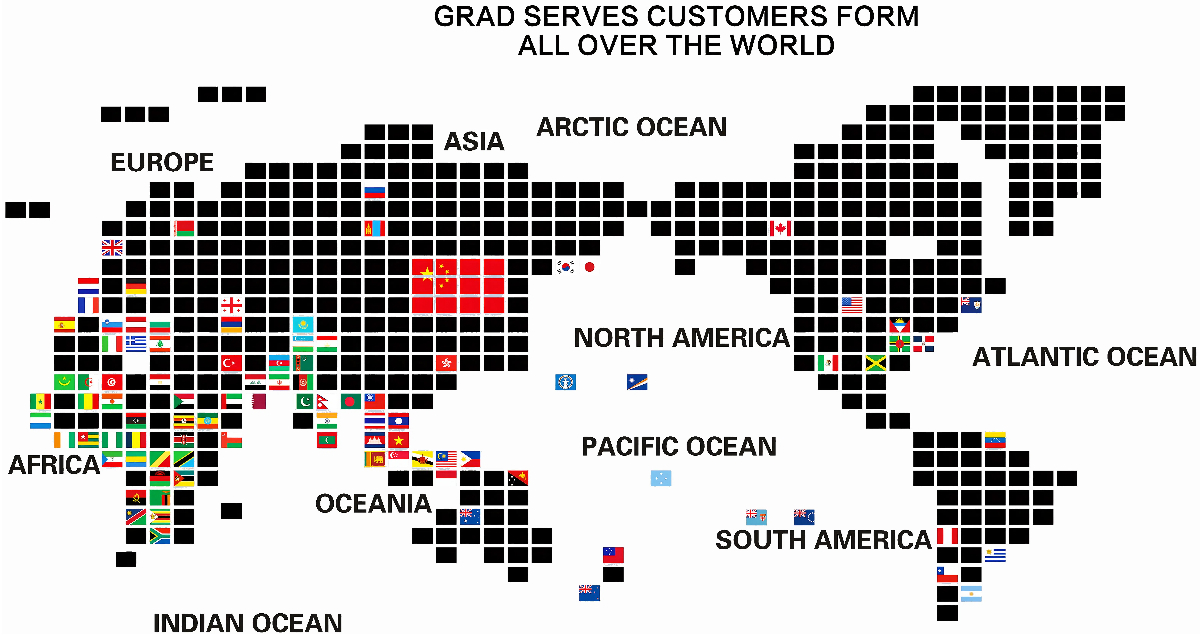

GRAD sales network covers over 100 countries and regions like America, Australia Indonesia, Malaysia, UAE, Thailand, Nigeria etc and has established branch company in USA, and set up offices in Cambodia and Thailand to make overall layout of global market.

Express and payment

1. Delivery Day: 20 days after deposit is confirmed.

2. Delivery Term: FOB,CIF,CFR or EXW are welcomed.

3. Payment Term: T/T,30% deposit,70% before delivery or 100% Irrevocable L/C at sight.

4. Warranty: Warranty for 12 months from the date of shipment from the factory.

5. Payment Currency: USD,EUR or CNY.

6. For sample or small quantity one or two, We suggest Express DHL etc.