FRP Pipes

1.Top 3 brands and annual output manufacturers.

2.Qualified by Korean KS certificate, which is the only one in China.

3.Over 30+ years production experience since 1993.

4.The most advanced continuous winding production machine is used for FRP/GRP fabrication.

5.National level test laboratory to make sure the products performance.

6.50+ years of lifespan, durable products.

7.China national projects participation experience:

South-to-North Water Diversion Project

Yellow Water to East China Diversion Project

8.Overseas pipeline project achievements:

Yeosu Water Treatment Plant Project in South Korea

Sewage Pipeline Project in Battambang Province, Cambodia

Indonesia West Kalimantan 2 x 50 MW coal-fired power stations FRP pipe project

Introduction

The FRP pipes produced by GRAD group is divided into two types: Fiber wind FRP craft tube and Fiber wind FRP nip pipe.Fiber wind FRP pipe is the main product which develops the market successful, it mainly uses in the petroleum, the chemical industry,the electric power,the medicine area and so on. It has the advantage of light weight, high intensity the installing is very convenient.The fiber wind FRP nip pipe is the GRAD group after manufacturing many years successfully and the technical research and development to great today’s result. It is the representative of the reliability ,security and economy, mainly uses in buried the tube and long transport pipeline. It has the advantage of light weight corrosion resistance,long life service,the circulating and the service cost are low and so on may suggest the project serves lots of fee.

FRP winding pipe characteristics

1. Excellent physics mechanics characteristics

The density of the FRP tube material is 1.8-2.1g/cm3.It is about 25 percent of the steel. The density is higher than rolled steel , cast iron and plastic. The weight of the FRP tube is not more than 33 percent of the same specification steel tube, The physics mechanics characteristics. The FRP tube’s heat expanding modulus is almost the same as the steel. The heat exchange modulus is 0.5% of the steel. It is a good insulation material of heat and electricity.

2. Anti chemistry eroding, The using lifespan is longer

The FRP tube has the special characteristic of anti chemistry eroding, under the star studded condition of the tube. It depends on the request of the medium to choose the different anti eroding tube. As for the vertical burying FRP filling voile tube the lifespan must be more than 40 years.

3. Hydraulics characteristics

Excellent Hydraulics characteristics mean that a smaller pipe diameter or a smaller power delivery pump can be selected, so as to reduce the initial investment of pipeline engineering, save electricity and reduce operating costs

4. Low fee of installing and maintenance

The FRP tube doesn’t need special antisepticise disposal, heat preservation can reduce thinness, the pipeline is light, little suspending equipment tonnage, consume little power, long single FRP pipeline, few tie-in on the scene, so the construction is convenient.

5. Unpolluted medium

The FRP pipeline’s density is higher, no impurity peel off and shed, no cauterization, without microorganism and bacteria, so it will not bring any pollution to the transporting material.

Material | Fiber-wound fiberglass reinforced plastic | steel | Cast iron | PVC |

specific gravity | 1.8-2.1 | 7.84 | 7.84 | 1.4 |

Tensile strength | 160-320 | 380 | 187 | 50-60 |

Specific strength | 100-168 | 48.5 | 25.5 | 36.8 |

Coefficient of thermal expansion (10-6/℃) | 11.2 | 12.3 | 60-80 | |

Thermal conductivity coefficient | 0.48 | 113 | 0.21 |

About us

Shandong GRAD Group is a large modern enterprise with over two decades history. Our business started in 1993, with staff of over 2200, we are focus on R&D, production, marketing, installation and maintenance for central air conditioning system and G R P composite material products. We are committed to providing customers with one-stop central air-conditioning and FRP composite material product solutions.

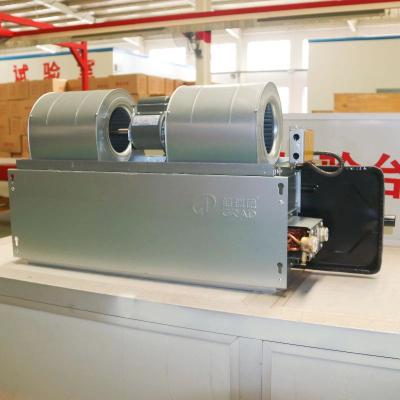

For central air conditioning products, we have production facility covering 450000 sqm, we can offer products for the whole system including chillers, heat pumps, cooling towers, A H U s, F C U s and ventilation products. To better participate international project, we have C T I, C E, A H R I certificates to guarantee our products quality.

For G R P composite material products, we have production facility covering 700000 sqm. With its feature of light weight, high strength, anti-corrosion and long service life, the G R P products are ideal replacement for steel products. We can offer process like vacuum injection, G R P winding, S M C mould pressing, molding pultrusion and hand paste. Based on different process, we can offer clients customized products.

GRAD international business starts in 2009, now its products have been exported to 100 countries and regions.

Our services

Before-sale services:

(1) Tell customers how to use our products and matters needing attention.

(2) Guide customers to choose the best and economic product, recover the investment within short time.

(3) Site inspection if you need.

In-Sale services:

(1)Quality control must be inspected strictly.

(2)In accordance with the agreements stipulated in the contract.

After-sale services:

(1) If the project needs our installation guidance, we can send our engineer and translator. We can also send customers installation video to

teach them how to fix and operate with our product.

(2) Usually, our product warranty is 18 months after leaving factory or 12 months after installation. within this months, all parts broken will be responsible for our factory.

(3) Regular contact with customer, consult with the customer feedback, come true with the customer's two-way communication.