Steel Water Tank

1.The appearance of the water tank is beautiful and elegant,one-time stretch forming,no welding is required,and the defects of the corrosion-resistant welding joint of the stainless steel welding water tank are eliminated.

2.The whole water tank is bolted;The size can be arbitrarily combined,and it is easy to assemble and disassemble;No welding equipment is needed during installation.

3.The assembled stainless steel water tank is simple and quick to construct,and does not require a argon arc welding welder.(Example:A50m3 water tank requires only 48 hours to install).

4.The water tank connectors are connected by special materials developed by the Grad Group.

5.The water tank sealing material is anti-aging,high temperature resistant,corrosion resistant,no secondary pollution,and the service life and sanitation are up to relevant standards.

6.The assembled stainless steel water tank has high preservation rate,the water tank is molded and detachable,and it can be used for secondary assembly.

Stainless steel water tank

Stainless steel water tanks refer to water tanks made from stainless steel plates through processes such as welding and assembly. Most stainless steel water tanks are made of stainless steel plates of materials such as 304, 316L, and 444, which are formed through die stamping and then assembled on site by welding. Compared with other water tanks, stainless steel water tanks have many features such as beautiful appearance, light weight, high strength, corrosion resistance, high temperature resistance, clean water quality, no seepage, earthquake resistance, no secondary water pollution, easy installation, no maintenance required and easy cleaning

Application:

Stainless steel water tank is suitable for large hotels,institutions,apartments,research and teaching buildings,food processing, medical and health,electronics industry and other places with high water quality requirements (Except the user of high chloride ion content in water).

Specification standard

No | Main dimensions mm | Thickness mm | |||||||||

Volume m³ | L | B | H | Side | |||||||

Bottom | Top | 1 | 2 | 3 | 4 | 5 | |||||

1 | 1 | 1000 | 1000 | 1000 | 1.5 | 1.0 | 1.5 | ||||

2 | 6 | 2000 | 2000 | 1500 | 2.0 | 1.0 | 2.0 | 1.5 | |||

3 | 10 | 2500 | 2000 | 2000 | 2.0 | 1.0 | 2.0 | 1.5 | |||

4 | 18.75 | 3000 | 2500 | 2500 | 2.5 | 1.0 | 2.5 | 2.0 | 1.5 | ||

5 | 30 | 4000 | 2500 | 3000 | 2.5 | 1.0 | 2.5 | 2.0 | 1.5 | ||

6 | 42 | 4000 | 3000 | 3500 | 3.0 | 1.0 | 3.0 | 2.5 | 2.0 | 1.5 | |

7 | 100 | 5000 | 5000 | 4000 | 3.0 | 1.0 | 3.0 | 2.5 | 2.0 | 1.5 | |

8 | 222.5 | 10000 | 5000 | 4500 | 3.5 | 1.0 | 3.5 | 3.0 | 2.5 | 2.0 | 1.5 |

9 | 1250 | 25000 | 10000 | 5000 | 3.5 | 1.0 | 3.5 | 3.0 | 2.5 | 2.0 | 1.5 |

Why choose GRAD water tank?

1.WRAS certified, reliable quality.

2.15+ years oversea installation experience, timely after-sale response.

3.31+ years FRP composite material products manufacturing experience, one-stop service for full range of water treatment products.

4.Different panel size options to meet customized capacity requirements.

5.Various steel accessories options to meet different applications.

6.Excellent agent policy to keep win-win cooperation with local agents.

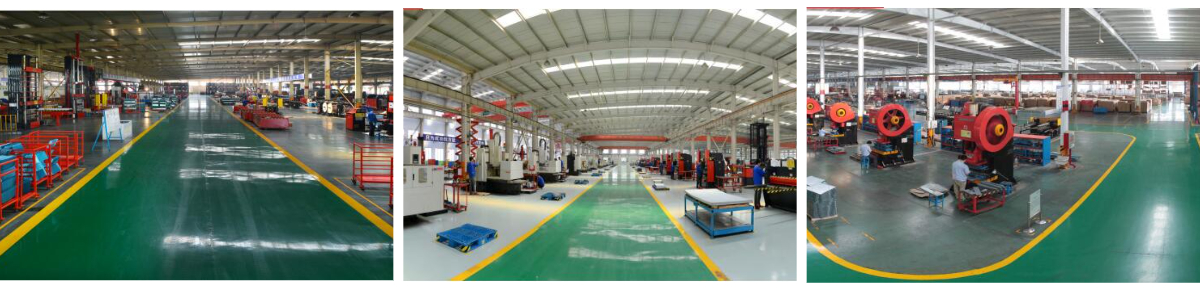

About us

Establised in 1993, GRAD Group covers an area of 1.15 million square meters and has more than 2,000 employees, with an annual output value of nearly 4 billion yuan. GRAD Group's main business: central air conditioning chiller and terminal products, FRP water tank, FRP winding pipe, FRP storage tank, wind turbine cabin cover, environmental protection equipment, and other more than 130 varieties. GRAD Group is the pillar enterprise of the “Dezhou Central Air-Conditioning City” named by the China Refrigeration and Air-Conditioning Industry Association. It ranks the top 10 among central air-conditioning enterprises in the country, The top 3 composite material enterprises,and gets the first-class qualification for the installation of national electromechanical equipment and the second-class qualification for air purification engineering. GRAD Group can undertake central air conditioning engineering, purification engineering construction.