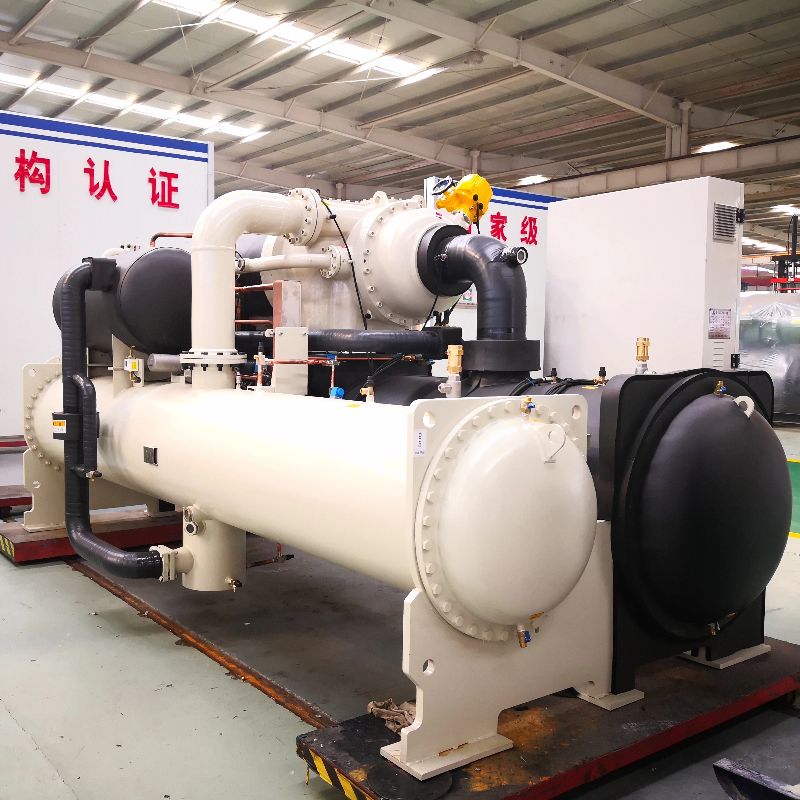

Industrial Water Chiller

1. Bipolar compression

Adopting bipolar compression enhances the energy efficiency of the unit and broadens the capacity adjustment range of the unit

2. National patent

High-efficiency falling film evaporation technology

3. Invention patent

Flash evaporation tank technology

4. Self-developed

Remote intelligent control

5. Anti-surge technology

The combination of prevention, control and alarm makes the unit safer and more reliable

Industrial Water Chiller

Industrial Water Chiller is the use of electricity as a power source, freon refrigerant in the evaporator refrigerant evaporation, freon evaporation wet steam compressor compressed into high temperature and high pressure gas, the water cooling condenser is condensed into a liquid, the expansion valve throttling recirculation into the evaporator. Thus, the freezing water at 7 C -12 C is made for air conditioning at the end of air conditioning.

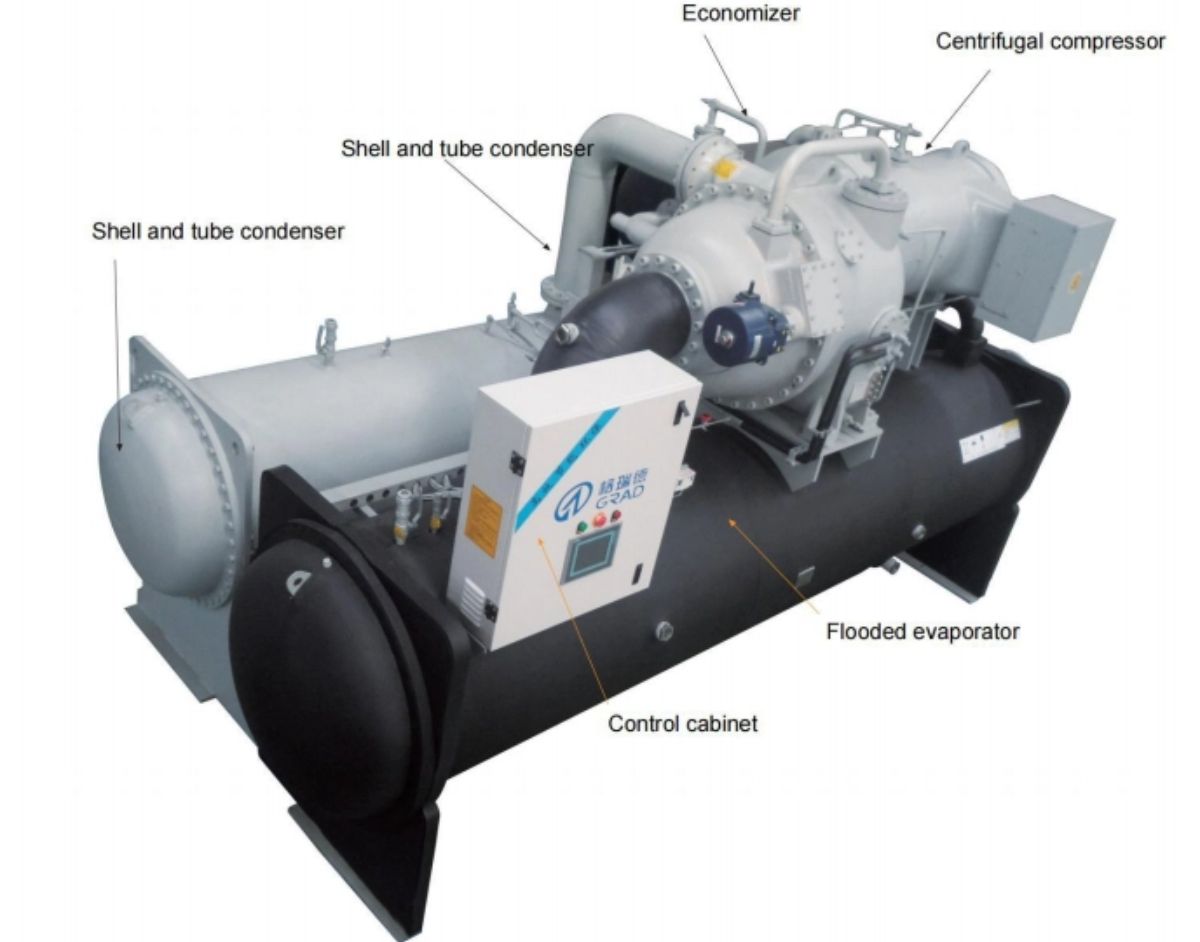

Unit features

(1)Unit adopts two-stage centrifugal compressor with high energy efficiency

•Three-phase bipolar squirrel cage induction motor Y- △ start, direct start or soft start.

•High efficiency two-stage compression and economizer design. Protection level - IP54.

•High-strength aluminum enclosed impeller. Enclosed impeller is more efficient than open type.

(2)The unit adopts SIEMENS microcomputer intelligent control

•Simple operation, complete protection, Chinese interface, real-time monitoring, clear display of all running data, extremely convenient operation. Capacity adjustment is wide with 10~100% stepless capacity adjustment.

•It has perfect protection functions, such as power protection, high voltage protection, low voltage protection, oil temperature protection, etc., which makes the unit running more reliable.

•The unit has advanced multiple anti-surge function, and adopts the combination of prevention, control and alarm, so that the unit can meet customers’ demand for cooling capacity in a safe range.

•Visually display switch state, analog state, input, alarm and fault, etc.

(3)Diversified unit throttling control programs

•According to different working conditions and requirements, three throttling programs are available: orifice plate, orifice plate and solenoid valve in parallel connection, orifice plate and electric control valve in parallel connection.

•Orifice plate+electric control valve in parallel connection is the most accurate for throttling control but the cost is higher, so it can be as an optional program.

•Each set of orifice plates is customized according to centrifuge and unit performance to achieve the best matching with unit performance.

•Since orifice plate has no any movable parts, its reliability is better than various throttle valves by mechanical transmission.

(4)Separate oil return system

•The oil pump is built in compressor with separate oil return and cooling system, making the compressor lubrication more reliable.

•The unit adopts injection pump as oil return component, and uses high pressure gas as power to complete oil return function at low pressure side.

Technical parameters table of centrifugal water cooled cold water chiller (Part I)

Model | LC350A | LC400A | LC450A | LC500A | LC550A | LC600A | LC650A | LC700A | LC750A | LC800A | LC850A | LC900A | ||

Cooling capacity | RT | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | |

KW | 1231 | 1407 | 1583 | 1759 | 1934 | 2286 | 2462 | 2638 | 2814 | 3165 | 3341 | 3165 | ||

104Kca/h | 106 | 121 | 136 | 151 | 166 | 197 | 212 | 227 | 242 | 257 | 272 | 272 | ||

Electric motor | Power (kw) | 208 | 242 | 277 | 306 | 334 | 340 | 369 | 400 | 425 | 452 | 483 | 513 | |

Power supply | 380-3ph-50hz | 6000/10000V-3ph-50hz | ||||||||||||

Cooling mode | Refrigerant spray cooling | |||||||||||||

Performance factor COP (KW/KW) | 5.92 | 5.81 | 5.72 | 5.75 | 5.8 | 6.2 | 6.19 | 6.16 | 6.21 | 6.22 | 6.19 | 6.17 | ||

refrigerant | R134a | |||||||||||||

Evaporator | Cold water flow (m3/h) | 212 | 242 | 272 | 302 | 333 | 363 | 393 | 423 | 454 | 484 | 514 | 544 | |

Cold water press drop ( kpa) | 65 | 84 | 82 | 86 | 87 | 84 | 81 | 81 | 87 | 88 | 87 | 87 | ||

Number of pass cold water inlet and outlet | 2 | |||||||||||||

Temperature ( ℃) | 12/7 | |||||||||||||

Connection diameter (DN) | 200 | 250 | 300 | |||||||||||

Condenser | Cooling water flow (m3/h) | 265 | 302 | 340 | 378 | 416 | 454 | 491 | 529 | 567 | 605 | 643 | 681 | |

Cooling water press drop ( kpa) | 70 | 85 | 87 | 84 | 89 | 87 | 80 | 77 | 84 | 88 | 85 | 84 | ||

Number of pass cooling water inlet and outlet | 2 | |||||||||||||

Temperature ( ℃) | 30/35 | |||||||||||||

Connection diameter (DN) | 200 | 250 | 300 | |||||||||||

Company Information

Establised in 1993, GRAD Group covers an area of 1.15 million square meters and has more than 2,000 employees, with an annual output value of nearly 4 billion yuan. GRAD Group's main business: central air conditioning chiller and terminal products, FRP water tank, FRP winding pipe, FRP storage tank, wind turbine cabin cover, environmental protection equipment, and other more than 130 varieties. GRAD Group is the pillar enterprise of the “Dezhou Central Air-Conditioning City” named by the China Refrigeration and Air-Conditioning Industry Association. It ranks the top 10 among central air-conditioning enterprises in the country, The top 3 composite material enterprises,and gets the first-class qualification for the installation of national electromechanical equipment and the second-class qualification for air purification engineering. GRAD Group can undertake central air conditioning engineering, purification engineering construction.

GRAD sales network covers over 100 countries and regions like America, Australia Indonesia, Malaysia, UAE, Thailand, Nigeria etc and has established branch company in USA, and set up offices in Cambodia and Thailand to make overall layout of global market.

Express and payment

1. Delivery Day: 20 days after deposit is confirmed.

2. Delivery Term: FOB,CIF,CFR or EXW are welcomed.

3. Payment Term: T/T,30% deposit,70% before delivery or 100% Irrevocable L/C at sight.

4. Warranty: Warranty for 12 months from the date of shipment from the factory.

5. Payment Currency: USD,EUR or CNY.

6. For sample or small quantity one or two, We suggest Express DHL etc.