Water Cooled Water Chiller

Test ability, technical level

1.GRAD has the National Laboratory of Air Conditioning Products recognized by CNAS, which is used for the design, development and experimental research of water-cooled chiller and the factory test of products.

2.Strict factory product quality control, so that users can buy at ease, with satisfaction.

3.GRAD screw type water cooled chiller series products ware tested by the national air conditioning quality testing center, the technical performance indicators are higher than GB/T184330.1-2007"Vapor compression cycle cold water (heat pump) unit Part 1: Industrial or commercial and similar uses of cold water (heat pump) units "standard, product quality is stable, reliable operation, has been praised by the majority of users at home and abroad.

Water Cooled Water Chiller

Water Cooled Water Chiller adopts the semi-closed double-screw compressor, and uses the single circuit or multi-circuit design. The protection and control facilities are placed in the control cabinet and the running state of the host is displayed on the computer monitor. All units are assembled in the factory and leave the factory after being operated and debugged. The application scope of this series of the units includes various commercial and civilian building facilities, such as shopping malls, office buildings,commercial buildings, factory workshops,

hotels, hospitals and so on.

Equipped with a cutting-edge PLC control system, the water-cooled water chiller ensures precise temperature regulation and energy management. The intelligent interface allows users to monitor operating parameters—such as cooling capacity, power consumption, and refrigerant pressure—in real time via touchscreen or remote devices. With adaptive load adjustment, the unit dynamically optimizes performance to match demand, further reducing energy consumption by up to 15%.

Environmental Sustainability

Aligned with global green initiatives, the chiller utilizes eco-friendly refrigerants (R134a or R513A) with low GWP (Global Warming Potential), complying with international environmental standards like EPA and EU F-Gas regulations. The compact design and reduced refrigerant charge minimize carbon footprint while maintaining high efficiency. Additionally, the unit’s noise levels are optimized to below 75dB, ensuring minimal disturbance in urban installations.

Customization & Scalability

To cater to diverse project needs, GRAD offers tailored solutions including modular designs for large-scale applications. Clients can choose between single-circuit units (for consistent loads) or multi-circuit systems (for zoned cooling), with optional heat recovery modules to repurpose waste heat for domestic hot water or industrial processes.

| A partial parameter table of water-cooled screw chiller R22 | ||||||||||||||||||

| Unit Model | LSW055 | LSW110 | LSW180 | LSW250 | LSW300 | LSWD110 | LSWD180 | LSWD240 | LSWD320 | LSWD380 | LSWD540 | LSWF560 | LSWF600 | LSWF720 | LSWF920 | LSWF1000 | ||

| Refrigeration capacity | KW | 193 | 387 | 630 | 880 | 1055 | 386 | 634 | 844 | 1126 | 774 | 1899 | 1960 | 2110 | 253 | 3240 | 3517 | |

| power supply | 3N-50HZ 380V | |||||||||||||||||

| Starting mode | Y-∆ or shunt winding | |||||||||||||||||

| Energy control | 25%-100% | 12.5%-100% | 6.25%-100% | |||||||||||||||

| Compressor | Type | Semi-closed screw type | ||||||||||||||||

| Quantity | 1 | 2 | 4 | |||||||||||||||

| Power input for refrigeration | KW | 40.8 | 82.3 | 131.3 | 104.5 | 215.5 | 71.6 | 134 | 179.6 | 234.6 | 278 | 398.6 | 418 | 448 | 527.1 | 675 | 732.7 | |

| Condenser | Type | Shell and tube heat exchanger | ||||||||||||||||

| Waterside resistance | KPa | 40-80 | ||||||||||||||||

| Connecting pipe specification | DN | 80 | 100 | 125 | 150 | 150 | 100 | 150 | 150 | 200 | 200 | 200 | 150 | 150 | 200 | 200 | 200 | |

| Water flow | m3/h | 36.8 | 80.7 | 130.9 | 183.7 | 218.5 | 78.7 | 132.1 | 176.1 | 234 | 277.6 | 395.2 | 409 | 440 | 525.8 | 673.4 | 730.9 | |

| Evaporator | Type | Shell and tube heat exchanger | ||||||||||||||||

| Waterside resistance | KPa | 40-80 | ||||||||||||||||

| Connecting pipe specification | DN | 80 | 100 | 125 | 150 | 150 | 100 | 150 | 150 | 200 | 200 | 200 | 150 | 150 | 200 | 150 | 150 | |

| Water flow | m3/h | 29.6 | 66.6 | 108.4 | 151.4 | 181.5 | 66.4 | 109 | 145.2 | 193.7 | 229.8 | 326.7 | 337 | 363 | 168.6 | 216.7 | 229.8 | |

| Partial heat recovery | Quantity | KW | 42 | 94 | 152 | 214 | 254.1 | 91.52 | 153.6 | 204.7 | 272.1 | 322.8 | 459.5 | 475.6 | 511.6 | 237.8 | 304.5 | 322.8 |

| Waterside resistance | Unit | 40-80 | ||||||||||||||||

| Connecting pipe specification | KW | 50 | 65 | 80 | 80 | 100 | 65 | 80 | 80 | 100 | 100 | 125 | 100X2 | 100X2 | 100X2 | 125X2 | 125X2 | |

| Water flow | m3/h | 7.1 | 16.1 | 26.2 | 36.7 | 43.7 | 15.7 | 26.4 | 35.2 | 46.8 | 55.5 | 79 | 81.8 | 88 | 105.2 | 134.7 | 146.2 | |

Application scope

Comfort air conditioning systems: large supermarkets or commercial complexes, hotels, shopping malls, office buildings, exhibition halls, airports, stadiums, etc.

Process air conditioning systems: electronics, biology, light textile, chemical engineering, metallurgy, pharmaceuticals, power, machinery, etc.

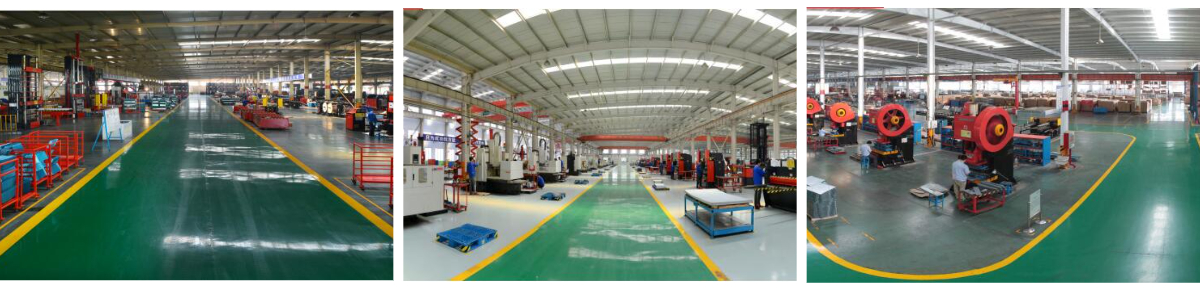

About us

GRAD Group founded in 1993 in Dezhou, shandong province,that is an enterprise group focusing on the artificial environment,and spanning five strategic new industries of new energy, new materials, equipment manufacturing, energy conservation and environmental protection, and information technology.GRAD products and services spread around the China and world with 100 countries and regions. They are widely used in infrastructure projects, commercial real estate, industrial manufacturing, agricultural development, electronic information, automobile engineering, medicine, environmental protection treatment, ocean engineering, rail transportation and other fields. With more than 10,000 employees, GRAD Group owned the production bases in Shandong, Guizhou, Sichuan, Xinjiang ,Inner Mongolia and so on.And GRAD Group has established r&d centers in Shanghai, Beijing, Jinan, Lanzhou and Los Angeles.

FAQ

Q1. Where is your loading port?

A: Qingdao/Shanghai/Tianjin, China or else port as for your request.

Q2. What's your company's main products?

A: Our company is specialized in central air-conditioning,ventilation and GRP Composite material products.

Q3. What's the MOQ for your production?

A: The MOQ is 1pcs or depends on your products requirements.

Q4. What’s your payment term.

A: T/T and L/C

Q5. What’s the lifespan of the unit?

A: Designed for 15–20 years of service, subject to proper maintenance per GRAD’s guideline