Refrigerated Water Chiller

Test ability, technical level

1.GRAD has the National Laboratory of Air Conditioning Products recognized by CNAS, which is used for the design, development and experimental research of water-cooled chiller and the factory test of products.

2.Strict factory product quality control, so that users can buy at ease, with satisfaction.

3.GRAD screw type water cooled chiller series products ware tested by the national air conditioning quality testing center, the technical performance indicators are higher than GB/T184330.1-2007"Vapor compression cycle cold water (heat pump) unit Part 1: Industrial or commercial and similar uses of cold water (heat pump) units "standard, product quality is stable, reliable operation, has been praised by the majority of users at home and abroad.

Water Cooled Screw Chiller adopts the semi-closed double-screw compressor, and uses the single circuit or multi-circuit design.Its parts are easy to maintain.The protection and control facilities are placed in the control cabinet and the running state of the host is displayed on the computer monitor. All units are assembled in the factory and leave the factory after being operated and debugged. The application scope of this series of the units includes various commercial and civilian building facilities, such as shopping malls, office buildings, commercial buildings, factory workshops, hotels, hospitals and so on.

1. High efficiency and low noise: it has a higher EER and the COP value can be as much as over 4.6.

2. Reasonable system structure: the unit can be horizontal or vertical which is easy to install.

3. Intelligent regulation: the unit can adjust automatically as per the loading, which can save energy a lot.

4. Good performance and reliable.

Applications:

This unit is mainly used for cooling in summer, which is widely used in comfort central air conditioning system for communal facilities like hotel, shopping mall, office building, exhibition hall, airport, gym etc. Meanwhile, it can meet the various requirements of process air conditioning system for industries like electricity, pharmacy, biology, light textile, metal and mechanical industries etc.

Components

1. Semihermetic screw refrigeration compressor, with simpler structure, even and continuous inlet and exhaust air, small running shock, high stability and long life span.

2. Shell & tube evaporator and condenser

3. Expansion valve: electronic expansion valve control system can meet as much as 2600 steps control precision, which can make the unit keep optimal condition.

4. All the assembly work will be finished in the factory and the unit can be delivered after qualified operation and trial test.

5. Microcomputer control system.

A partial parameter table of water-cooled screw chiller R22 | ||||||||||||||||||

Unit Model | LSW055 | LSW110 | LSW180 | LSW250 | LSW300 | LSWD110 | LSWD180 | LSWD240 | LSWD320 | LSWD380 | LSWD540 | LSWF560 | LSWF600 | LSWF720 | LSWF920 | LSWF1000 | ||

Refrigeration capacity | KW | 193 | 387 | 630 | 880 | 1055 | 386 | 634 | 844 | 1126 | 774 | 1899 | 1960 | 2110 | 253 | 3240 | 3517 | |

power supply | 3N-50HZ 380V | |||||||||||||||||

Starting mode | Y-∆ or shunt winding | |||||||||||||||||

Energy control | 25%-100% | 12.5%-100% | 6.25%-100% | |||||||||||||||

Compressor | Type | Semi-closed screw type | ||||||||||||||||

Quantity | 1 | 2 | 4 | |||||||||||||||

Power input for refrigeration | KW | 40.8 | 82.3 | 131.3 | 104.5 | 215.5 | 71.6 | 134 | 179.6 | 234.6 | 278 | 398.6 | 418 | 448 | 527.1 | 675 | 732.7 | |

Condenser | Type | Shell and tube heat exchanger | ||||||||||||||||

Waterside resistance | KPa | 40-80 | ||||||||||||||||

Connecting pipe specification | DN | 80 | 100 | 125 | 150 | 150 | 100 | 150 | 150 | 200 | 200 | 200 | 150 | 150 | 200 | 200 | 200 | |

Water flow | m3/h | 36.8 | 80.7 | 130.9 | 183.7 | 218.5 | 78.7 | 132.1 | 176.1 | 234 | 277.6 | 395.2 | 409 | 440 | 525.8 | 673.4 | 730.9 | |

Evaporator | Type | Shell and tube heat exchanger | ||||||||||||||||

Waterside resistance | KPa | 40-80 | ||||||||||||||||

Connecting pipe specification | DN | 80 | 100 | 125 | 150 | 150 | 100 | 150 | 150 | 200 | 200 | 200 | 150 | 150 | 200 | 150 | 150 | |

Water flow | m3/h | 29.6 | 66.6 | 108.4 | 151.4 | 181.5 | 66.4 | 109 | 145.2 | 193.7 | 229.8 | 326.7 | 337 | 363 | 168.6 | 216.7 | 229.8 | |

Partial heat recovery | Quantity | KW | 42 | 94 | 152 | 214 | 254.1 | 91.52 | 153.6 | 204.7 | 272.1 | 322.8 | 459.5 | 475.6 | 511.6 | 237.8 | 304.5 | 322.8 |

Waterside resistance | Unit | 40-80 | ||||||||||||||||

Connecting pipe specification | KW | 50 | 65 | 80 | 80 | 100 | 65 | 80 | 80 | 100 | 100 | 125 | 100X2 | 100X2 | 100X2 | 125X2 | 125X2 | |

Water flow | m3/h | 7.1 | 16.1 | 26.2 | 36.7 | 43.7 | 15.7 | 26.4 | 35.2 | 46.8 | 55.5 | 79 | 81.8 | 88 | 105.2 | 134.7 | 146.2 | |

Company Information

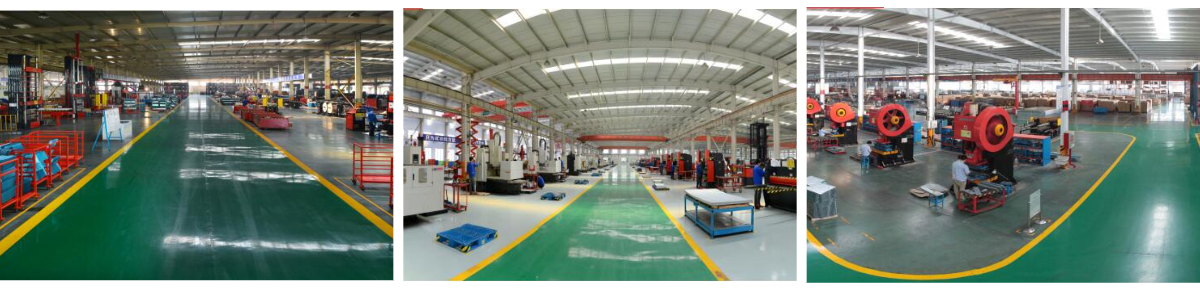

GRAD Group devotes itself to be a central air conditioning customization expert around you and provides you a comprehensive energy solution, GRAD possesses national mechanical and electrical equipment installation Class I qualification and purification equipment installation Class II qualification. GRAD has the overall project contacting ability. It has contracted national class and provincial class technology research projects for many times. The accumulated patents for technolog achievements has passed 110 items. There are more than 300 senior engineers available for central air conditioning design and solution. The 700,000 ㎡ manufacturing base includes the whole central air conditioning series: from chiller to terminal products. The high efficient falling film centrifugal chiller maintains domestic leading position and the large fan wall air handling unit has filled domestic blank and been listed in the national torch plan. GRAD has the national class air conditioning testing center and has passed CNAS certification. The products quality can be well guaranteed. Some of projects gained China Construction Project Luban Prize and National High Quality Project. At the same time, GRAD has established more than 30 offices all over China, such as Beijing, Tianjin, Shenyang, Xi’an, Wuhan, Nanjing, etc. The sales, design, installation and after sales network has covered every corner of China. Moreover, its products have been exported to more than 100 countries.