Residential Cooling Tower

1.CTI certification

Authoritative certification, exported to the European and American markets

2. Long lifespan

The vacuum intake air duct and pultruded panel are made of fiberglass reinforced plastic, which is of high strength and corrosion resistance

3. Low noise

Patented technology of integral water spray packing, with lower noise

4. Efficient cooling

Integral packing, uniform water distribution and large heat exchange area

5. Easy installation

Modular design: Steel parts are welded into blocks before leaving the factory, reducing on-site welding

Residential Cooling Tower

Cooling tower is mainly applied to air conditioning cooling system, freezing series, injestion molding, leather, power generation, and steam turbine, aluminum profile processing, air compressor, industrial cooling tower, cooling for industrial production or refrigeration technology process.

The main functions of cooling towers are as follows

Cooling: The cooling tower achieves heat dissipation by spraying high-temperature water or other liquids onto the packing layer, utilizing the heat exchange between water and air, thereby reducing the liquid's temperature to the set range.

Realize recycling: The cooling tower conveys the dissipated water back to the equipment for recycling, thereby reducing water consumption and improving the utilization efficiency of water resources.

Protecting equipment: In industrial production, some equipment needs to operate in high-temperature environments. However, high temperatures can have adverse effects on the equipment. Therefore, cooling towers are required to reduce the temperature of the equipment to the normal range to ensure its normal operation.

Energy conservation: Cooling towers can reduce the temperature of liquids to the set range by utilizing natural wind or forced convection through fans, thereby reducing energy consumption and improving energy utilization efficiency.

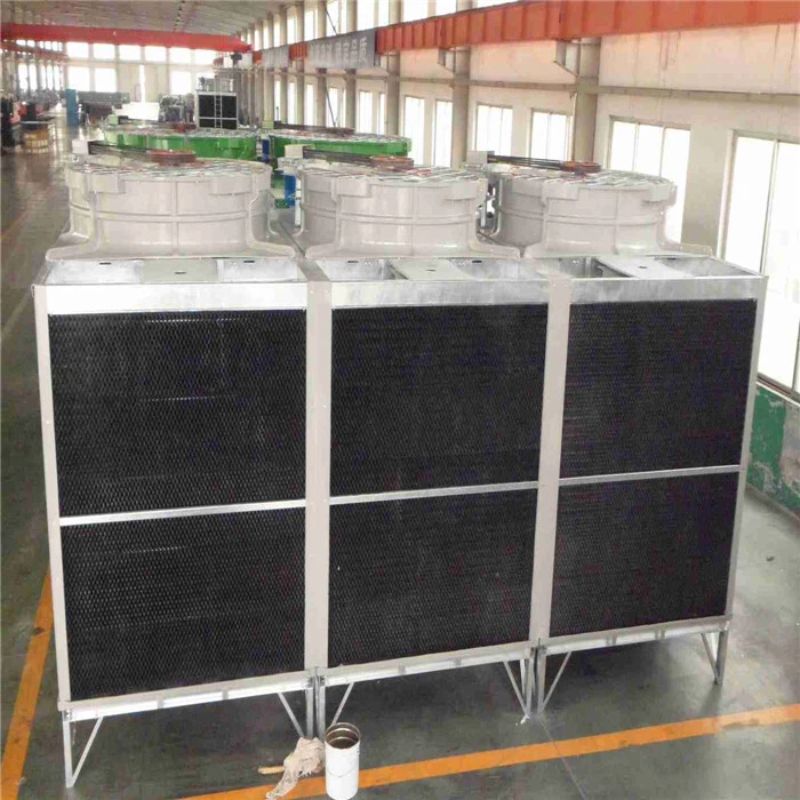

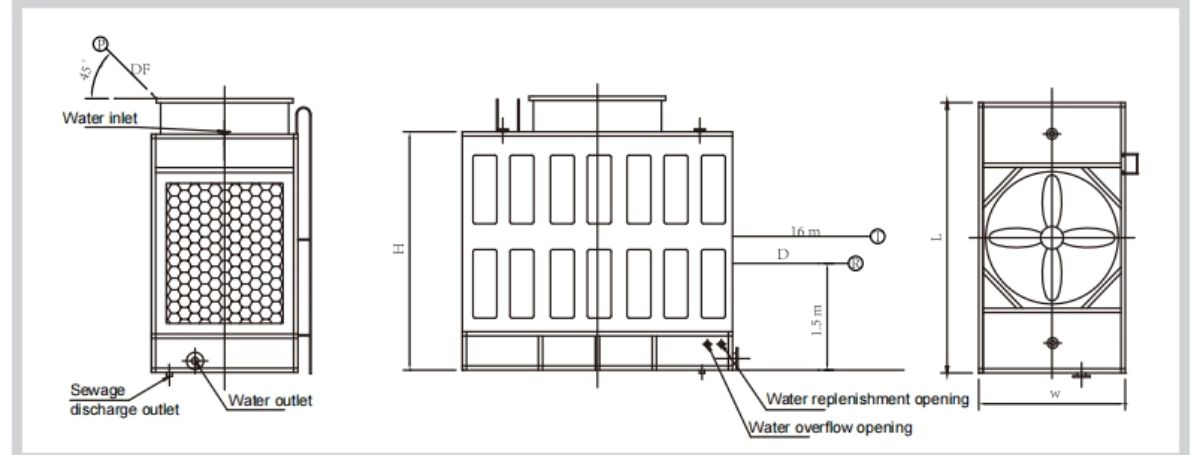

Cross Flow series Cooling Tower is an improved model on structure and technology from the traditional squqare cooling tower .Every internal component is appropriately used.All parts and materials are rigidly checked and tested to make sure their service life and operation.The improved mechaniaed technology not noly ensures the high quality of the cooling tower.but also e ecively reduces the dead weight of the tower,making the Cross Flow series Cooling Tower series endowed with advantages ofsmall in size,light in weight,high e cient,long service life and stable operation.Equipped with frequency inventer,this series can autornatically regulate the fan speed as the cooling water temperature changes under diferent temperature and load which can save energy and lower noise.

Technical parameters of BHD series of square cross-flow GRP cooling towers

Technical and specification parameters of BHD-100~BHD- 700

Model | Water yield m3/h | Cooling efficient×103 K cal/h | Motor power KW | The fan diameter Φ mm | The tower body lift mH2O | Overall dimensions (mm) | Noise dB(A) | ||||

L | W | H | P | R | T | ||||||

BHD-100 | 100 | 500 | 2.2 | 1768 | 3.5 | 3800 | 2060 | 3350 | 60.1 | 57.4 | 50.0 |

BHD-125 | 125 | 625 | 3 | 1768 | 3.5 | 4200 | 2060 | 3350 | 61.2 | 57.6 | 51.2 |

BHD-150 | 150 | 750 | 3 | 2168 | 3.6 | 4200 | 2460 | 3350 | 61.4 | 57.8 | 51.5 |

BHD-175 | 175 | 875 | 4 | 2168 | 3.6 | 4600 | 2460 | 3350 | 62.3 | 58.1 | 52.9 |

BHD-200 | 200 | 1000 | 4 | 2560 | 3.8 | 4600 | 2860 | 3350 | 62.5 | 58.7 | 53.4 |

BHD-225 | 225 | 1125 | 5.5 | 2560 | 3.9 | 5000 | 2860 | 4000 | 63.1 | 59.3 | 53.8 |

BHD-250 | 250 | 1250 | 5.5 | 2954 | 4.0 | 5000 | 3260 | 4000 | 63.4 | 59.8 | 54.5 |

BHD-300 | 300 | 1500 | 7.5 | 2954 | 4.0 | 5400 | 3260 | 4000 | 64.3 | 60.6 | 55.2 |

BHD-330 | 330 | 1650 | 7.5 | 3340 | 4.2 | 5400 | 3660 | 4000 | 63.9 | 60.4 | 54.7 |

BHD-370 | 370 | 1850 | 11 | 3340 | 4.4 | 5800 | 3660 | 4500 | 64.2 | 60.7 | 55.1 |

BHD-400 | 400 | 2000 | 11 | 3744 | 4.9 | 5800 | 4060 | 4500 | 64.7 | 61.3 | 55.7 |

BHD-450 | 450 | 2250 | 15 | 3744 | 4.9 | 6200 | 4060 | 4500 | 65.3 | 61.4 | 56.1 |

BHD-500 | 500 | 2500 | 15 | 4140 | 5.0 | 6600 | 4460 | 5000 | 65.4 | 61.7 | 56.3 |

BHD-600 | 600 | 3000 | 18.5 | 4140 | 5.3 | 7000 | 4460 | 5000 | 66.1 | 62.4 | 57.1 |

BHD-700 | 700 | 3500 | 18.5 | 4540 | 5.3 | 7400 | 4860 | 5000 | 67.3 | 63.6 | 58.2 |

Note:

1. Test the cooling efficiency under the working conditions of the water inlet temperature of 37°C, water outlet temperature of 32°C, ambient wet bulb temperature of 28°C and atmospheric pressure of 99.4kPa.

2.The indicated noise value is the measured value at a running frequency of 50Hz. Please see the frequency comparison table for actual running noise. (The data is subject to change without prior notice)

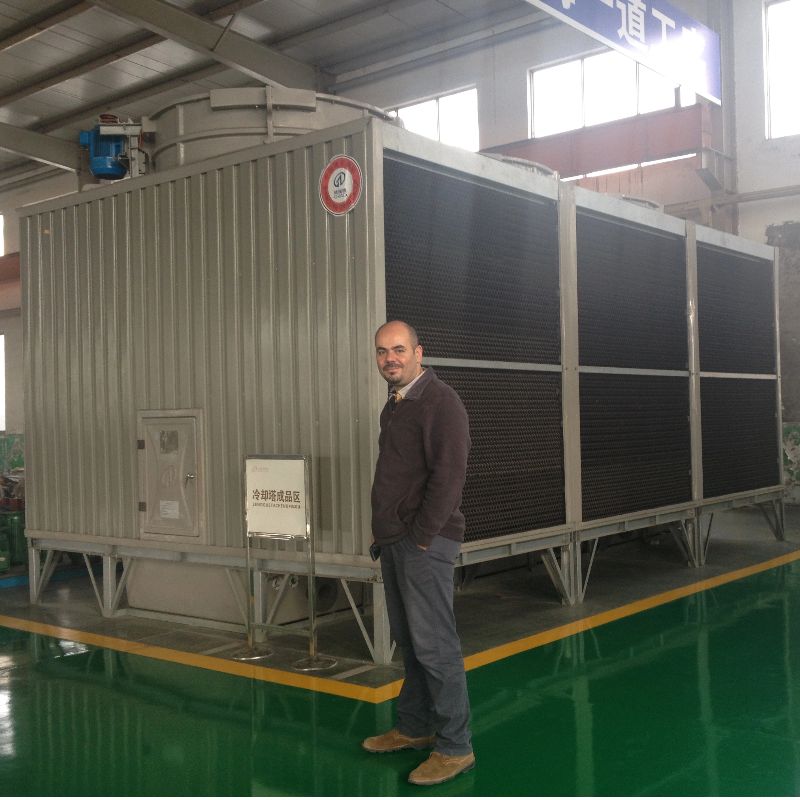

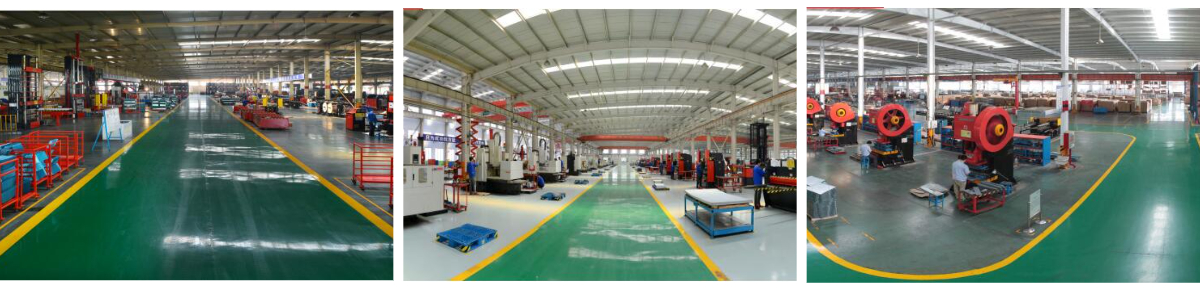

About us

GRAD Group Establised in 1993, GRAD Group covers an area of 1.15 million square meters and has more than 2,000 employees, with an annual output value of nearly 4 billion yuan. GRAD Group's main business: central air conditioning chiller and terminal products, FRP water tank, FRP winding pipe, FRP storage tank, wind turbine cabin cover, environmental protection equipment, and other more than 130 varieties.

Main products:Central air conditioners,ventilators ,GRP Composite material products,Environment protection products

Employment : 2500+ employees

Registered capital: ¥ 100 million

Equipment price : ¥370 million

Total capital :¥ 925 million

Annual output value: ¥over 3 billion

Design team:300+

Overseas offices:

1. Thailand and Cambodia offices

2. USA branch company