Air Source Heat Pump Installation

1.It operates efficiently within an ultra-wide ambient temperature range of -30℃ to 43℃

2. Precise frost measurement, rapid defrosting, reduced defrosting frequency, and shortened defrosting time

3. Mobile APP operation, remote control, fault warning, and online diagnosis

4. High-efficiency shell and tube heat exchange technology, water-side heat exchanger and flow protection, ultra-high energy efficiency ratio

5. It has a wide range of applications and is suitable for radiator heating, floor radiant heating, central air conditioning cooling and heating

Air Source Heat Pump Installation

Product introduction:

Air source heat pump is a kind of energy-saving device that can make the heat flow from the low heat source air to the high heat source.

The GRAD air source heat pump unit is equipped with a self-developed NB-iot Internet of Things remote intelligent control module. It can be operated via a mobile phone APP, eliminating the need for dedicated personnel to stand by. It offers fault early warning prompts and online diagnosis. It can operate efficiently in an ambient temperature range of -30℃ to 43℃, with a maximum water outlet temperature of 60℃. It has various terminal forms and is suitable for radiator, floor radiant, central air conditioning cooling and heating. The national patented intelligent defrosting technology accurately detects frost, quickly defrosts, significantly reduces the frequency of defrosting, and greatly shortens the defrosting time. In addition, this unit also has unique advantages such as modular customization, no need to build a machine room, environmental protection and energy conservation, high efficiency and low noise, and wide application range.

Air-cooled modular cold (hot) water unit

● The use of electronic expansion valve intelligent adjustment of refrigerant flow, more accurate control, more reliable unit operation.

● The use of environmental protection R410A refrigerant, wide operating range, refrigeration operating environment temperature of 18 ~ 48℃, heating operating environment temperature range of -15 ~ 25℃, applicable to a wider range of areas.

| Heat pump unit parameter table (low temperature type) | ||||||||

| unit type | AR40BHR | AR50BHR | AR80BHR | AR100BHR | AR160BH | AR200BHR | ||

| Normal Temperature Condition | Heating Capacity | kW | 49 | 57 | 98 | 114 | 196 | 228 |

| Input Power | kW | 11.1 | 12.9 | 22.2 | 25.8 | 44.4 | 51.6 | |

| Water yield | L/h | 1054 | 1225 | 2108 | 2450 | 4216 | 4900 | |

| Rated Working Condirion | Heating Capacity | kW | 37 | 44 | 74 | 88 | 148 | 176 |

| Input Power | kW | 10.4 | 12.1 | 20.8 | 24.2 | 41.6 | 48.4 | |

| Water yield | L/h | 795 | 946 | 1590 | 1892 | 3180 | 3784 | |

| Low Temperature Condirion | Heating Capacity | kW | 28 | 30 | 52 | 60 | 104 | 120 |

| Input Power | kW | 10.8 | 12.6 | 21.6 | 25.2 | 43.2 | 50.4 | |

| Water yield | L/h | 486 | 560 | 972 | 1120 | 1944 | 2240 | |

| Climatic type (Outdoor ambient temperature range) | ‘-30℃~48℃ | |||||||

| Maximum outlet temperature | 60℃ | |||||||

| Power supply specification | 3N~50Hz 380V | |||||||

| Maximum operating current of the unit | A | 30 | 40 | 60 | 80 | 120 | 160 | |

| Refrigerant | R410A | |||||||

| Waterside heat exchanger | Circulating water flow | m3/h | 8.4 | 9.8 | 16.9 | 19.6 | 33.7 | 39.2 |

| resistance | kPa | 15~40 | ||||||

| Inlet and outlet nozzle size | DN | 40 | 40 | 65 | 65 | 80 | 80 | |

| Overall dimension | Length | mm | 1200 | 1200 | 2110 | 2110 | 2110 | 2110 |

| Width | mm | 1080 | 1080 | 1080 | 1080 | 2405 | 2405 | |

| Height | mm | 2160 | 2160 | 2160 | 2160 | 2160 | 2160 | |

| Noise | dB(A) | 66 | 67 | 68 | 69 | 70 | 70 | |

| Unit weight | kg | 400 | 450 | 800 | 850 | 1600 | 1650 | |

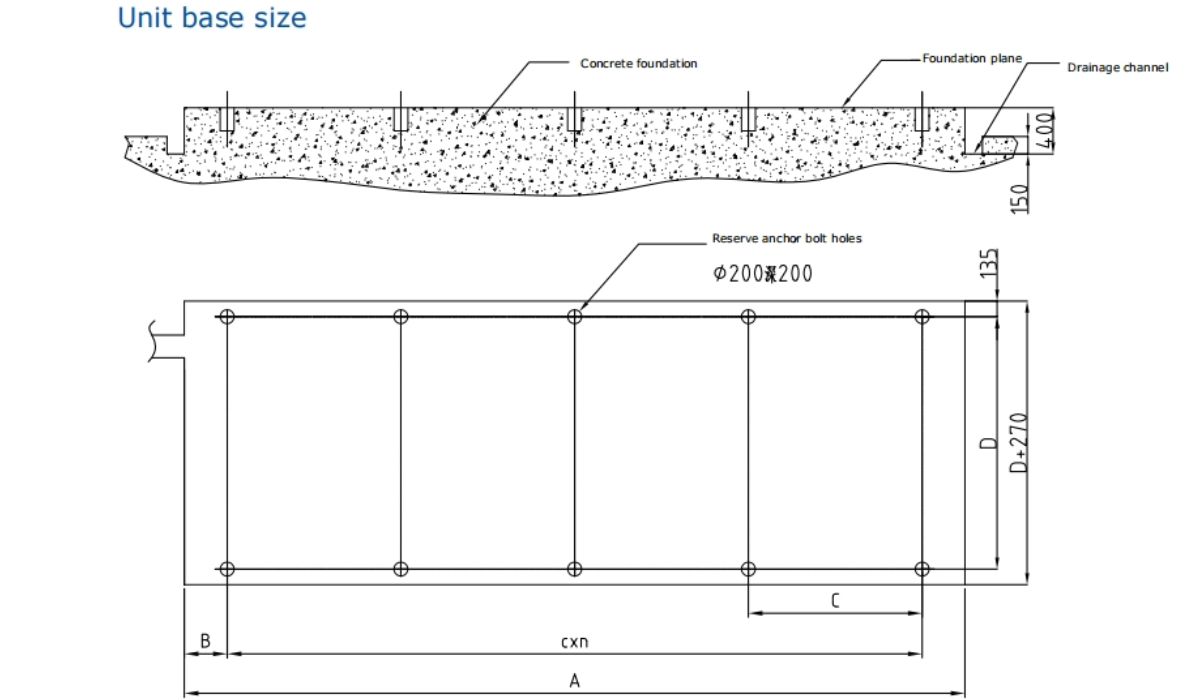

Unit installation guide

Note:

1. The installation base should be designed by professionals according to the site conditions.

2. The installation foundation must be concrete or steel structure, the strength can withstand the operating weight of the equipment, the upper surface is required to be smooth and reserved drainage tank.

3. Adding rubber shock pad between the unit and the foundation, install shock absorber when the model is large.

4. The unit is fixed with M16 anchor bolts.

5. More than 1.5m space should be left around the unit to facilitate air circulation and equipment maintenance.

6. Space above 2.0-2.5m should be reserved above the unit to ensure smooth air flow.