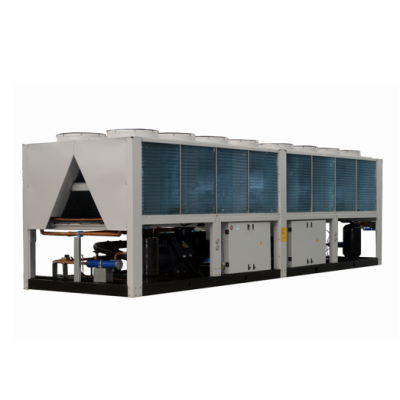

Screw Water Chiller

1.GRAD has the National Laboratory of Air Conditioning Products recognized by CNAS, which is used for the design, development and experimental research of water-cooled chiller and the factory test of products.

2.Strict factory product quality control, so that users can buy at ease, with satisfaction.

3.GRAD screw type water cooled chiller series products ware tested by the national air conditioning quality testing center, the technical performance indicators are higher than GB/T184330.1-2007"Vapor compression cycle cold water (heat pump) unit Part 1: Industrial or commercial and similar uses of cold water (heat pump) units "standard, product quality is stable, reliable operation, has been praised by the majority of users at home and abroad.

The water-cooled screw chiller adopts the semi-closed double-screw compressor, and uses the single circuit or multi-circuit design. The protection and control facilities are placed in the control cabinet and the running state of the host is displayed on the computer monitor. All units are assembled in the factory and leave the factory after being operated and debugged. The application scope of this series of the units includes various commercial and civilian building facilities, such as shopping malls, office buildings,commercial buildings, factory workshops, hotels, hospitals and so on.

The design, manufacturing and inspection of GRAD water cooled screw chiller shall be in accordance with theGB/T18430.1-2007 Water Chilling (Heat Pump) Packages Use the Vapor compression Cycle-Part 1:Water Chilling (Heat Pump) Packages for Industrial& Commercial and Similar Application.

High efficiency compressor

The unit adopts wellknown brand semi-closed screw compressor. Compared with piston compressor, semi-closed screw compressor has the following advantages:

(1)Fewer parts (about 1 /3 of the piston compressor), simple structure, less wearing parts, high reliability, long life

(2) The compressor: uniform and continuous suction and exhaust, low exhaust temperature, small vibration, insensitive to wet compression, and strong resistance to liquid shock;

(3) COP of dry unit can reach more than 4.6, COP of full liquid/falling film unit can reach more than5.3

(4) In terms of energy regulation, screw compressors have more advantages, achieving 25-100% stepless energy regulation.

Shell and tube evaporator

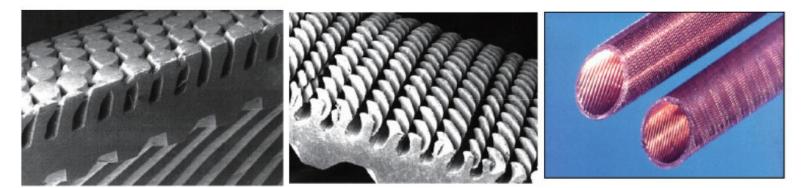

1. The dry unit matches the dry shell and tube evaporator with high efficiency heat exchange tube

(1) The most advanced DAE efficient evaporation heat transfer tube, multi-head spiral fin and spiral protruding on the surface of the tube can greatly improve the heat transfer coefficient and heat transfer capacity.

(2) The internal structure of the evaporator is optimized and the efficient liquid homogenizer is configured to solve the problem of the uniformity of the distribution of cooling in the system.

(3) Improve the sealing structure of the refrigerant water baffle, solve the problems of the baffle leakage, greatly improve the heat transfer efficiency of the evaporator, so as to ensure that the unit reaches a higher performance level.

(4) The unique heat exchanger cooling process design technology is used to rationally match the system to ensure the balanced relationship between the refrigeration process and the water side cooling capacity, and give full play to the high efficiency of the heat exchanger:meanwhile

Reasonable system matching makes the unit more energy saving.

Ultra-efficient falling film evaporator

(1) Single circuit or double circuit refrigerant system design: the refrigerant evaporates in the shell side, and the cold water flows through the pipe to be cooled. All heat exchange tubes are infiltrated in the refrigerant, Effectively increase the heat transfer efficiency, improve the evaporation temperature.

(2) Shell: The production and test are in accordance with the provisions of NB/T47012-2020"Pressure vessel for refrigeration equipment" standard.

(3) Copper pipe: seamless copper pipe for full liquid unit using the most advanced internal and external fin strengthening technology in China.

(4)Effectively control the liquid level with the electronic expansion valve. Make the unit to achieve the best operating state.

(5) Compared with the full liquid evaporator, the falling film evaporator reduces the amount of refrigerant charge, improves the of about 10%, of the heat exchange efficiency, and makes the oil return more stable and the operation more reliable.

Shell and tube water-cooled condenser with high performance heat exchange tube

(1) The most advanced DAE high efficiency condensation heat transfer tube, with multiple spiral ribs and spiral

protruding on the outer surface of the tube, so that the heat transfer coefficient and heat transfer capacity are greatly improved.

(2) The optimized design of the internal structure greatly improves the anti-corrosion and anti-fouling ability of the condenser, and gives full play to the heat transfer effect of the condenser, so as to ensure that the unit achieves a higher performance level.

(3) Shell and tube condenser is also installed the safety valve, air relief valve, etc., to ensure the safety of shell and tube condenser and the convenience of cleaning and maintenance.

Unit vibration avoidance design, ensure the unit low noise, low vibration

(1) The spring or rubber shock absorber is set below the compressor of the unit, and the vibration absorption

efficiency is above 85%, that is, the vibration transmission rate is less than 0.15, which reduces the vibration of the unit and the system vibration, thus reducing the noise of the unit.

(2) All the pipes of the unit system are fixed with anti-vibration plastic pipe clips to reduce the noise caused by the vibration of the unit and the system.

Brand refrigeration system accessories

(1) All parts of the cooling system used parts from famous brand manufacturers, such as detachable filter dryer, expansion valve, solenoid valve, sight glass, high and low pressure sensors, etc adopt the world class famous brand manufacturers products, to ensure that the unit has a high level of performance.

(2) All materials of the unit can be entered into the factory after 100% inspection to ensure the high reliability of the refrigeration system of the unit.

Advanced and highly reliable intelligent control system and control technology

(1) Multi-machine control system in addition to single-machine automatic configuration and functions, but also has the display of multi-unit operation, according to the return water temperature computer automatically determine whether the air conditioning system is part of the unit or all the unit operation.

(2) Equipped with RS485/RS232 communication interface, convenient for users to achieve centralized monitoring and remote monitoring of the unit.

(3) The unit has the function of controlling the balanced operation of multiple compressors to ensure the efficient operation of the unit.

(4) The falling film unit adopts the national invention patent "real-time control of refrigerant flow" to make the unit more accurate and stable operation.

Unit energy regulation mode

The unit performs logical calculation according to the chilled water return water or outlet water temperature to control the operating state and start and stop of the unit. Each unit adopts segmental or stepless energy regulation to achieve efficient and energy-saving operation of the unit.

The structure of the unit is reasonable, the installation and debugging, the maintenance and management are convenient and fast

(1) The layout of the unit is reasonable, and the installation and maintenance space is optimized, which is convenient for daily cleaning, maintenance and overhaul.

(2) The unit leaves the factory in the form of the whole machine, the low-pressure part is wrapped with the insulation layer before leaving the factory, the system has been filled with fluorine refueling, and only connect the water pipe after arriving at the site. After the power is turned on, the unit can be turned on.

(3) The computer will automatically start the pump motor and compressor according to the program, and coordinate the control of the refrigeration, delay, interlock, protection and automatic adjustment of temperature of the unit. Thereafter, the unit runs at the set temperature under computer control, and automatically adjusts the energy according to the change of the inlet temperature of the evaporator.

The installation of the unit is flexible, which can be controlled on-site or remotely, and is easy to check and maintain.

Due to the efficiency and stability of the falling film chiller, it can completely replace the full liquid chiller, and the falling film chiller has the following advantages:

(1) The use of high efficiency falling film evaporator, its heat transfer efficiency increased by more than 15% than the traditional full liquid evaporator , the unit operating costs saving 30%. The application in the unit can make the unit performance coefficient up to the national energy-saving certification level one. At the same time, the falling film evaporator successfully obtained the national utility model patent.

(2) Using the national invention patent "refrigerant flow real-time control", real-time flow control according to the change of user load, more accurate control precision, more reliable unit operation; At the same time, the level

control of the unit is more stable, so that the required deviation of the unit to the basic levelness is within10%, which is a leading position in the same industry.

The use of independent research and development has successfully obtained the national utility model patent of ultra-high efficiency and low resistance oil separator, oil separation efficiency of up to 99.99%, the unit oil return more reliable, longer service life of the unit.

(3) Adopt the first domestic liquid distribution technology and the condenser refrigerant export structure with national utility model patent technology, reduce the refrigerant charge amount, reduce the utilization rate of refrigerant, and the unit is more environmentally friendly.

(4)Intelligent remote monitoring technology is used to realize monitoring functions such as "unit alarm message reminder", "unit fault remote processing", and "unit operation data memory". Let the user use more assured, unit operation more efficient.

Product application scope

Screw water cooled chiller is widely used in hotels, shopping malls, office buidings, exhibiion halls, airports, stadiums and other public faclites comfort central air condtioning system,and it can meet the process air condtioning system different requirements of electronic, pharmaceutical, biological, textile, chemical, metallurgy, pharmaceutical, electic power, machinery and otherindustries.

Structure Diagram of Water Cooled Screw Chiller

No. | Name | No. | Name |

1 | Compressor | 8 | Expansion valve |

2 | Evaporator | 9 | Safety valve |

3 | Condenser | 10 | Exhaust valve |

4 | Electric cabinet | 11 | Emergency stop |

5 | Dry filter | 12 | Touch screen |

6 | Sight glass | 13 | Unit base |

7 | Solenoid valve |

About us

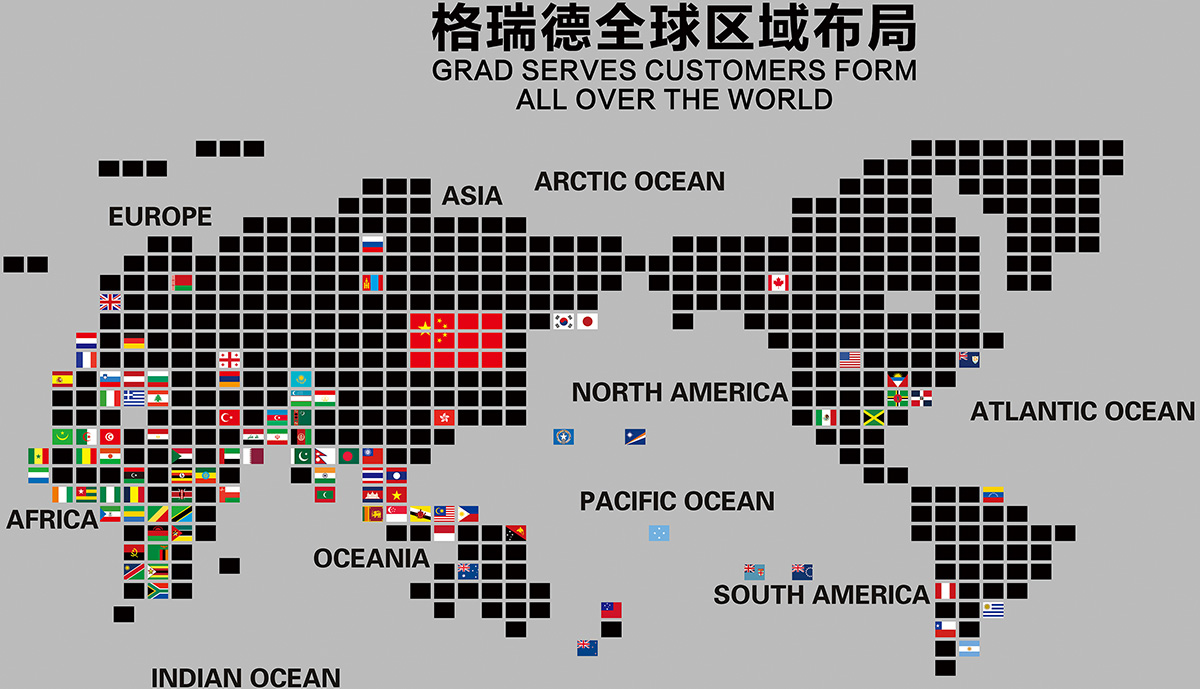

GRAD sales network covers over 100 countries and regions like America, Australia Indonesia, Malaysia, UAE, Thailand, Nigeria etc and has established branch company in USA, and set up offices in Cambodia and Thailand to make overall layout of global market.

Manufacturer:Shandong GRAD Group Co.,Ltd.

Established Time:1993

Covers an area of:700,000sqm

Main products:Central air conditioners,ventilators ,GRP Composite material products,Environment protection products

Employment : 2500+ employees

Registered capital: ¥ 100 million

Equipment price : ¥370 million

Total capital :¥ 925 million

Annual output value: ¥over 3 billion

Design team:300+

Overseas offices:

1. Thailand and Cambodia offices

2. USA branch company

FAQ

Q1. Where is your loading port?

A: Qingdao/Shanghai/Tianjin, China or else port as for your request.

Q2. What's your company's main products?

A: Our company is specialized in central air-conditioning,ventilation and GRP Composite material products.

Q3. What's the MOQ for your production?

A: The MOQ is 1pcs or depends on your products requirements.

Q4. What’s your payment term.

A: T/T and L/C.

Q5. Where is your factory?

A:We are in Dezhou, Shandong province. 1 hour to Beijing and 4 hours to Shanghai by bullet train. Our nearest airport is Jinan Yaoqiang airport.