Product Description

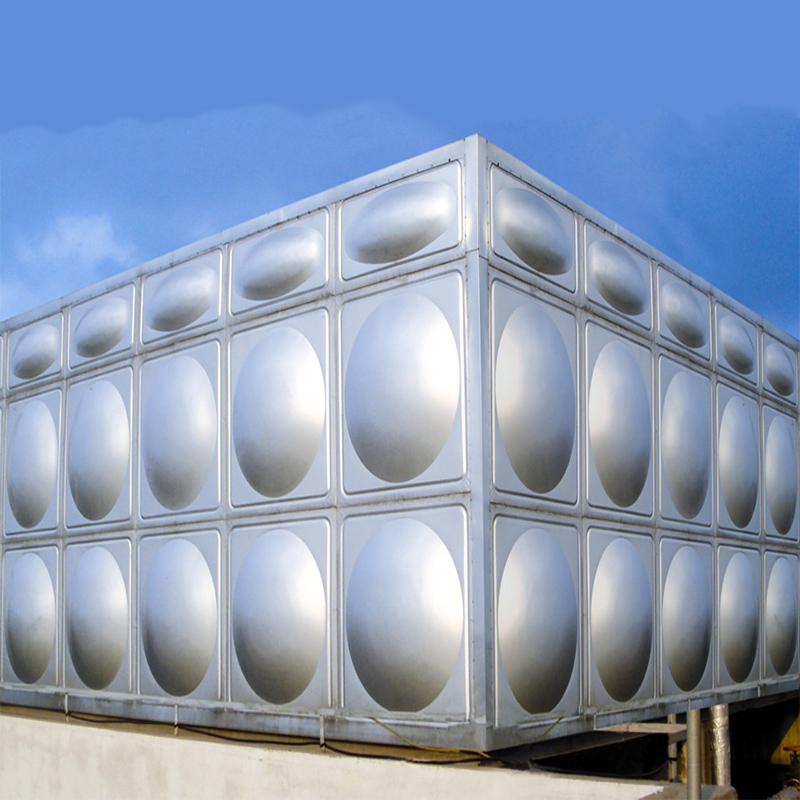

1.Stainless steel water tank is generally made of SUS304 stainless steel sheet,which has stable physical and chemical proper- ties,no pollution to water quality,and ensures clean and hygienic water quality;

2.Stamping and forming,high strength,lightweight,neat appearance,beautiful and elegant;

3.The water tank panel is generally made of above 3042B board with high nickel 8.0,the surface is smooth and beautiful,and easy to clean;

![Stainless Water Tank Stainless Water Tank]()

4.Due to the dense oxide layer on the surface,the corrosion resistance is superior and the sealing performance is good; 5.High impact resistance and strong seismic performance;

6.Compared with other types of water tanks,the selection of high quality materials;High quality food grade stainless steel SUS304 greatly prolongs the service life of the water tank,and it s better prevent secondary pollution of water quality.

7.The structure is unique and reasonable:The high-strength stamping panel and the uniform stainless steel ribs in the tank make the pressure uniform and reasonable.

8.Quick construction:standard stamping module 1500×1000,1500×500,1000×1000,1000×5000,500×500mm free assembly on-site assembly and welding,no lifting equipment required.

![Stainless Water Tank Stainless Water Tank]()

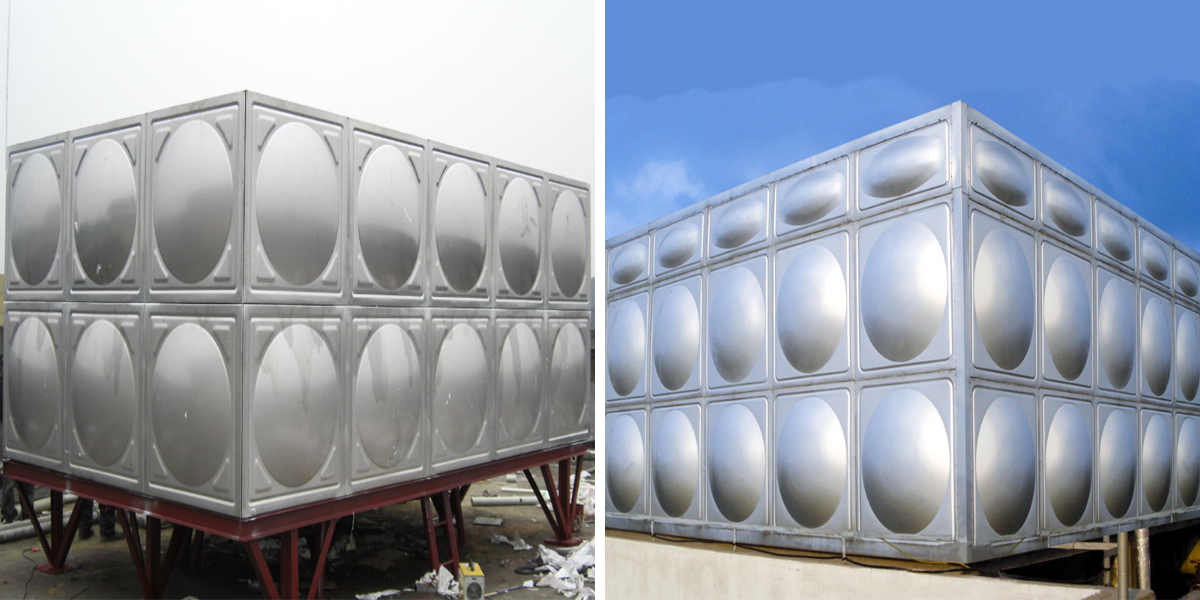

Application

Stainless steel water tank is suitable for large hotels,institutions,apartments,research and teaching buildings,food processing, medical and health,electronics industry and other places with high water quality requirements (Except the user of high chloride ion content in water).

Specification Standard

No | Main dimensions mm | Thickness mm |

Volume m³ | L | B | H | Side |

Bottom | Top | 1 | 2 | 3 | 4 | 5 |

1 | 1 | 1000 | 1000 | 1000 | 1.5 | 1.0 | 1.5 |

|

|

|

|

2 | 6 | 2000 | 2000 | 1500 | 2.0 | 1.0 | 2.0 | 1.5 |

|

|

|

3 | 10 | 2500 | 2000 | 2000 | 2.0 | 1.0 | 2.0 | 1.5 |

|

|

|

4 | 18.75 | 3000 | 2500 | 2500 | 2.5 | 1.0 | 2.5 | 2.0 | 1.5 |

|

|

5 | 30 | 4000 | 2500 | 3000 | 2.5 | 1.0 | 2.5 | 2.0 | 1.5 |

|

|

6 | 42 | 4000 | 3000 | 3500 | 3.0 | 1.0 | 3.0 | 2.5 | 2.0 | 1.5 |

|

7 | 100 | 5000 | 5000 | 4000 | 3.0 | 1.0 | 3.0 | 2.5 | 2.0 | 1.5 |

|

8 | 222.5 | 10000 | 5000 | 4500 | 3.5 | 1.0 | 3.5 | 3.0 | 2.5 | 2.0 | 1.5 |

9 | 1250 | 25000 | 10000 | 5000 | 3.5 | 1.0 | 3.5 | 3.0 | 2.5 | 2.0 | 1.5 |

Packaging and Shipping

![Water Storage Tanks Water Storage Tanks]()

About us

![Water Storage Tanks Water Storage Tanks]()

![Water Storage Tanks Water Storage Tanks]()

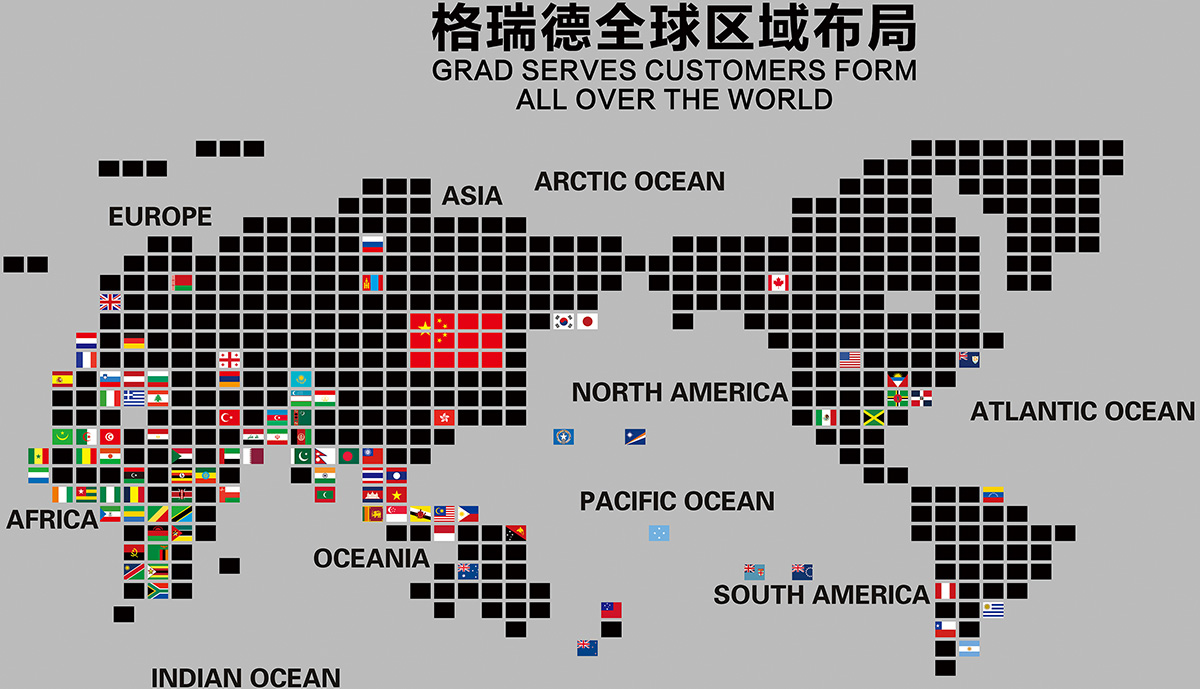

GRAD's sales network extends to over 100 countries and regions, including the United States, Australia, Indonesia, Malaysia, the UAE, Thailand, Nigeria, and more. The company has established a branch in the USA and set up offices in Cambodia and Thailand to support its comprehensive global market strategy.

![Water Storage Tanks Water Storage Tanks]()

Manufacturer:Shandong GRAD Group Co.,Ltd.

Established Time:1993

Covers an area of:700,000sqm

Main products:Central air conditioners,ventilators ,GRP Composite material products,Environment protection products

Employment : 2500+ employees

Registered capital: ¥ 100 million

Equipment price : ¥370 million

Total capital :¥ 925 million

Annual output value: ¥over 3 billion

Design team:300+

Overseas offices:

1. Thailand and Cambodia offices

2. USA branch company

FAQ

Q1: Where is your loading port?

A: Our main loading ports are Qingdao, Shanghai, and Tianjin, China. Other ports can be arranged upon request.

Q2: What are your company’s main products?

A: We specialize in central air-conditioning systems, ventilation equipment, and GRP (Glass Reinforced Plastic) composite material products.

Q3: What is your minimum order quantity (MOQ)?

A: The MOQ is 1 piece, or it can vary depending on the specific product requirements.

Q4: What are your payment terms?

A: We accept T/T and L/C payments.

Q5: Where is your factory located?

A: Our factory is located in Dezhou, Shandong Province—just 1 hour from Beijing and 4 hours from Shanghai by high-speed train. The nearest airport is Jinan Yaoqiang International Airport.