Fan Coil Unit

1.30+ years manufacturer

2.AHRI & CE certified.

3.1500sets/day production capacity to guarantee timely delivery.

4.Fast reaction for after-sales problem.

5.Multiple types with various models to meet customization requirements.

6.Patent appearance design.

7.Production and sales integration, better understand market requirements to offer OEM/ODM service.

8.Factory direct sales to offer cost-effective product.

The GRAD fan coil unit, with a national patent for appearance, features a compact and sturdy structure. The entire unit is lightweight and aesthetically pleasing, with a thin body design that can effectively save indoor space. The surface cooler adopts high-quality air conditioning purple copper tubes, combined with high-efficiency hydrophilic aluminum foil window aluminum fins. The tubes are mechanically expanded as a whole and formed in one piece. The tubes and fins are closely combined. The overall heat exchange area of the surface cooler is large. With multiple reverse flow designs, the heat exchange efficiency is high, and the energy efficiency exceeds the national standard by more than 15%. The fan motor is optimally matched, with a large fan wheel running at a low speed to enhance the fan's efficiency. High-efficiency sound-absorbing and heat-insulating materials are adopted to reduce the operating noise of the unit while ensuring the air volume and static pressure at the outlet. The noise level is 1 to 2db lower than the national standard. It has a wide range of air volume, with a maximum supply air volume of 3400m ³ /h. Grede fan coil units offer a wide variety of products that can be customized. There are six structural forms to choose from, including horizontal concealed installation, horizontal exposed installation, vertical concealed installation, vertical exposed installation, ceiling-mounted cassette type and high static pressure large air volume type, with an extremely high cost performance.

Fan coil units are ideal terminal products for central air conditioning. Fan coil units are one of the terminal devices of air conditioning systems, composed of small fans, motors, and coils, etc. When chilled water or hot water flows through the coils, it exchanges heat with the air outside the coils, cooling, dehumidifying or heating the air to regulate the indoor air parameters. It is mainly used as a terminal device for cooling and heating in application.

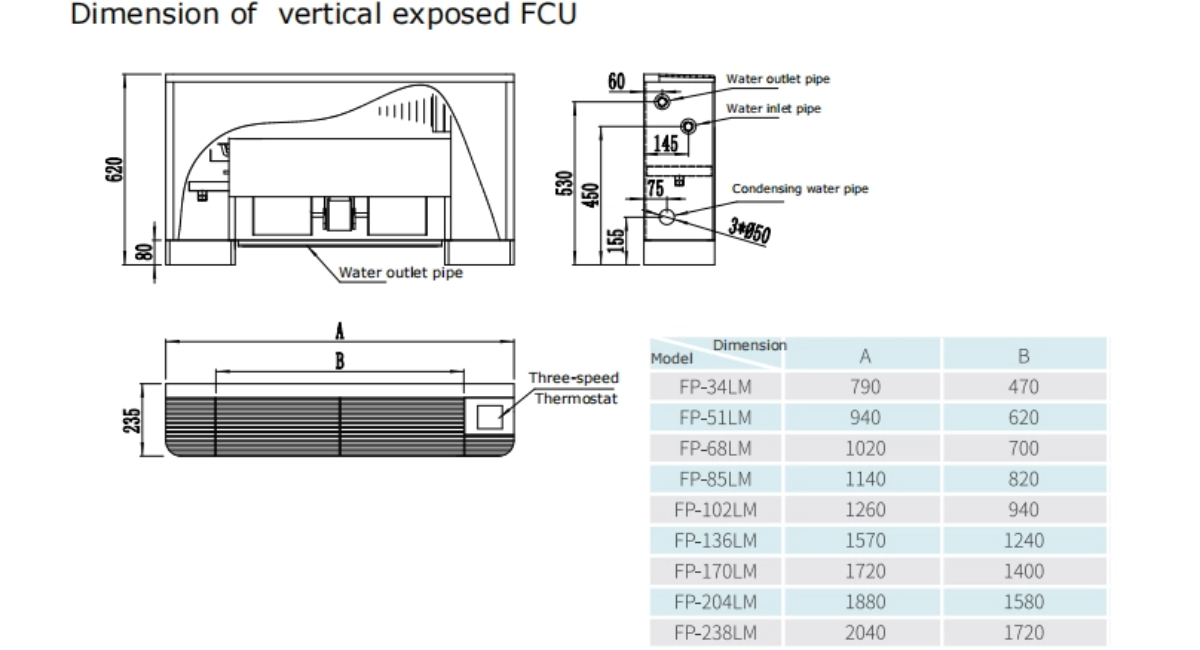

FP-LM Vertical exposed type

The electrostatic painting shell makes it elegant color and appearance. It can be put on the floor directly and match well with indoor decoration. It is easy to mount,demount and maintain and is of reliable performance.

Model No. | FP-34LM | FP-51LM | FP-68LM | FP-85LM | FP-102LM | FP-136LM | FP-170LM | FP-204LM | FP-238LM |

Air Volume (m³/h) | 340 | 510 | 680 | 850 | 1020 | 1360 | 1700 | 2040 | 2380 |

Cooling Capacity(kw) | 1.8 | 2.7 | 3.6 | 4.5 | 5.4 | 7.2 | 9 | 10.8 | 12.6 |

Heating Capacity(Kw) | 2.7 | 4.05 | 5.4 | 6.75 | 8.1 | 10.8 | 13.5 | 16.2 | 18.9 |

Power Supply | 220V/1PH/50Hz | ||||||||

Power Input (W) | 36 | 50 | 60 | 74 | 93 | 130 | 147 | 183 | 221 |

Noise (dB) | 37 | 39 | 41 | 43 | 45 | 46 | 48 | 50 | 52 |

Water volume(kg/h) | 310 | 470 | 620 | 780 | 930 | 1240 | 1550 | 1860 | 2170 |

Water resistance(kPa) | ≤30 | ||||||||

Weight(kg) | 27 | 32 | 33.5 | 36 | 39 | 52 | 61.5 | 64.5 | 67.5 |

Water Plate | Iron plate with paiting and insulated | ||||||||

Maximum working pressure(MPa) | 1.6 | ||||||||

Inlet and Outlet water pipe | Rc 3/4" (DN20) internal thread ,DN20 | ||||||||

Condensate pipe | R2 3/4" (DN20) internal thread ,DN20 | ||||||||

About us

GRAD Group devotes itself to be a central air conditioning customization expert around you and provides you a comprehensive energy solution, GRAD possesses national mechanical and electrical equipment installation Class I qualification and purification equipment installation Class II qualification. GRAD has the overall project contacting ability. It has contracted national class and provincial class technology research projects for many times. The accumulated patents for technological achievements has passed 150 items. There are more than 300 senior engineers available for central air conditioning design and solution. The 700,000 ㎡ manufacturing base includes the whole cental air conditioning series: from chiller to terminal products. The high efficient falling film centrifugal chiller maintains domestic leading position and the large fan wall air handling unit has filled domestic blank and been listed in the national torch plan. GRAD has the national class air conditioning testing center and has passed CNAS certification. The products quality can be well guaranteed. Some of projects gained China Construction Project Luban Prize and National High Quality Project.At the mean while, GRAD has established more than 30 offices allover China, such as Beijing, Tianjin, Shenyang, Xi’an, Wuhan, Nanjing, etc. The sales, design, installation and after sales network has covered every corner of China. Moreover, its products have been exported to more than 100 countries.

GRAD sales network covers over 100 countries and regions like America, Australia Indonesia, Malaysia, UAE, Thailand, Nigeria etc and has established branch company in USA, and set up offices in Cambodia and Thailand to make overall layout of global market.

Fault 1: Water leakage

The drip tray overflowed. The common reasons are: the drainage outlet (pipe) is blocked, the water is not discharged or the drainage is not smooth.

1. The drip tray is tilted

2. The vent valve is not closed

3, the pipe joints are not tightly connected

4, the tuyere water leakage. Water leakage of tuyere can be used ABS material tuyere

Fault 2: The blowing wind is not cold enough (hot)

1. Improper setting of temperature gear;

2, there is air in the coil;

3. Abnormal water supply temperature;

4. Insufficient water supply;

5. Coil fin oxidation.