Fan Coil Heater

Why choose us ?

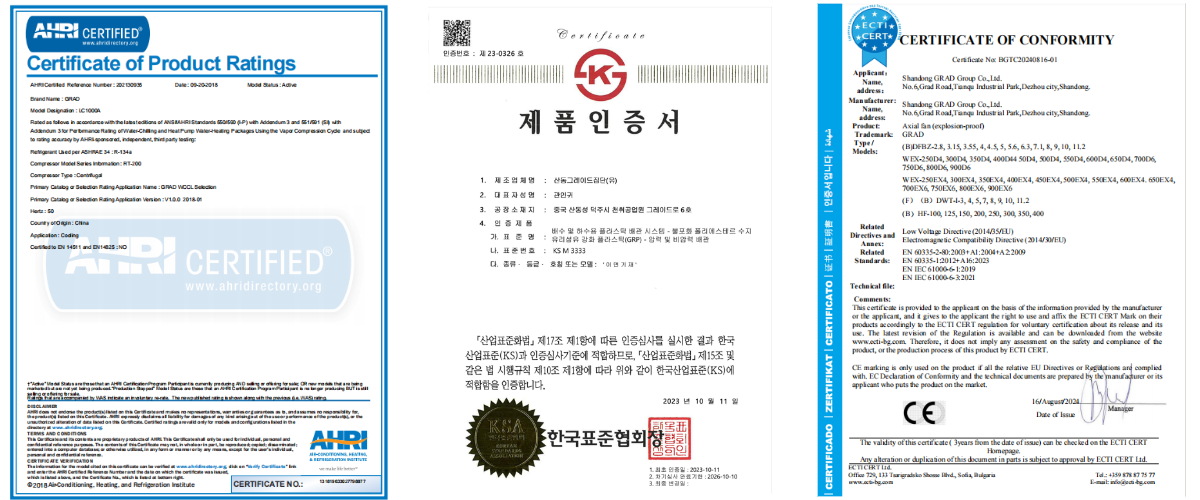

1.With AHRI and CE certificate.

2.Professional team with over 30 years industry knowledge.

3.Oversea installation.

4.Customization accepted.

5.we are factory,OEM/ODM welcome.

6.1500sets/day production capacity to guarantee timely delivery.

7.Fast reaction for after-sales problem.

Fan Coil Heater

FCU product

Fan Coil Heater mainly consists of centrifugal fan and heat exchanger etc., which is one of the terminals in the central air conditioning system. It has been widely applied in air conditioning occasions of civil or industrial buildings with large space or of multiple rooms like hotel, restaurant, factory, exhibition hall, shopping mall and office buildings.

It can meet the requirements of cooling, dehumidification and heating etc., which can create a fresh, quiet and year-round balmy working and living conditions.

Introduction

FCU improved the performance after optimized design;There are high efficiency type and standard type.The standard FCU can meet the national standard parameters;And the high efficiency FCU can meet the parameters higher 20% than national standard

Application

GRAD fan coil units are widely used in hotels,restaurants,factories,hospitals,exhibitions,shopping malls and office buildings.

Specifications

Air volume=340-2380m3/h

The rated cooling capacity=1.8-12.6kw

The rated heating capacity=2.7-18.9kw

The input power=36-221W

Model No. | FP-34LM | FP-51LM | FP-68LM | FP-85LM | FP-102LM | FP-136LM | FP-170LM | FP-204LM | FP-238LM |

Air Volume (m³/h) | 340 | 510 | 680 | 850 | 1020 | 1360 | 1700 | 2040 | 2380 |

Cooling Capacity(kw) | 1.8 | 2.7 | 3.6 | 4.5 | 5.4 | 7.2 | 9 | 10.8 | 12.6 |

Heating Capacity(Kw) | 2.7 | 4.05 | 5.4 | 6.75 | 8.1 | 10.8 | 13.5 | 16.2 | 18.9 |

Power Supply | 220V/1PH/50Hz | ||||||||

Power Input (W) | 36 | 50 | 60 | 74 | 93 | 130 | 147 | 183 | 221 |

Noise (dB) | 37 | 39 | 41 | 43 | 45 | 46 | 48 | 50 | 52 |

Water volume(kg/h) | 310 | 470 | 620 | 780 | 930 | 1240 | 1550 | 1860 | 2170 |

Water resistance(kPa) | ≤30 | ||||||||

Weight(kg) | 27 | 32 | 33.5 | 36 | 39 | 52 | 61.5 | 64.5 | 67.5 |

Water Plate | Iron plate with paiting and insulated | ||||||||

Maximum working pressure(MPa) | 1.6 | ||||||||

Inlet and Outlet water pipe | Rc 3/4" (DN20) internal thread ,DN20 | ||||||||

Condensate pipe | R2 3/4" (DN20) internal thread ,DN20 | ||||||||

About us

GRAD Group devotes itself to be a central air conditioning customization expert around you and provides you a comprehensive energy solution, GRAD possesses national mechanical and electrical equipment installation Class I qualification and purification equipment installation Class II qualification. GRAD has the overall project contacting ability. It has contracted national class and provincial class technology research projects for many times. The accumulated patents for technological achievements has passed 150 items. There are more than 300 senior engineers available for central air conditioning design and solution. The 700,000 ㎡ manufacturing base includes the whole cental air conditioning series: from chiller to terminal products. The high efficient falling film centrifugal chiller maintains domestic leading position and the large fan wall air handling unit has filled domestic blank and been listed in the national torch plan. GRAD has the national class air conditioning testing center and has passed CNAS certification. The products quality can be well guaranteed. Some of projects gained China Construction Project Luban Prize and National High Quality Project.At the mean while, GRAD has established more than 30 offices allover China, such as Beijing, Tianjin, Shenyang, Xi’an, Wuhan, Nanjing, etc. The sales, design, installation and after sales network has covered every corner of China. Moreover, its products have been exported to more than 100 countries.

Failure 1:water leakage

Water tray overflow. Common caused by blocked drainage,the water can’t be drained out or poor drainage.

1. Drain tray is inclined.

2. Relief valve does not close.

3. Pipe connectors are poor sealed.

4. Air vent leakage, ABS air vents can be replacement.

Failure 2: supply air is lack of cooling/heating.

1. Improper setting of temperature gear.

2. There is air in the fan coil unit.

3. Abnormal water supply temperature.

4. Insufficient water supply.

5. Fins of cooling coil are of oxidation.Here’s a continuation of the content in the same technical style