Glycol Chiller Air Conditioner

Compact & Space-Saving – Small footprint, easy installation & maintenance.

Smart & Energy-Efficient – Auto-load adjustment for optimal performance.

Quiet & Reliable – High-efficiency scroll compressor, low noise & long lifespan.

Intelligent Control – Real-time monitoring, diagnostics, and safety protection.

Modular & Scalable – Flexible configuration (2-8 modules), large cooling capacity.

Multi-Protection System – Safeguards against freezing, phase loss, overheating, etc.

Glycol Chiller Air Conditioner

The GRAD air-cooled scroll chiller (heater) unit adopts refrigeration components and control components of internationally renowned brands, and is equipped with an advanced intelligent control solution. After long-term stable operation verification, it features high efficiency and energy conservation, environmental friendliness, and stability and reliability. With a variety of specifications and complete functions, it can achieve interlocking control of 8 units and be connected to the building control system (BAS), easily meeting the air conditioning needs of different occasions. The air-cooled scroll type cold (hot) water unit has multiple advantages such as no cooling water system, simple pipeline, flexible installation, moderate investment, short construction period, and the ability to be invested in phases. It is widely used in various comfortable and artistic occasions such as villas, hotels, hospitals, office buildings, restaurants, supermarkets, and theaters.

Product Advantages

①The unit has a compact structure, occupies a small area, and features a simple pipeline design. It only requires external water pipes and is easy to install and maintain.

② Intelligent control: The unit can automatically adjust the output of the compressor put into operation according to the load changes, ensuring that the unit maintains the best coordination with the highest efficiency at all times.

③ It adopts imported fully enclosed scroll refrigeration compressors. It features high efficiency, low noise, small vibration, reliable operation and long service life.

④ It adopts a microcomputer control system, featuring powerful safety protection, communication, fault diagnosis, automatic adaptation and other functions. It can automatically monitor various parameters and operating conditions during the operation of the unit.

⑤ The units are divided into integral type and modular type. The modular unit is assembled from 2 to 8 modules and features large cooling capacity, mutual backup, and intermittent operation.

⑥It provides multiple protection functions such as high and low pressure protection, anti-freezing protection for chilled water, power phase sequence protection, phase loss protection, insufficient water flow protection, and compressor motor overheating protection.

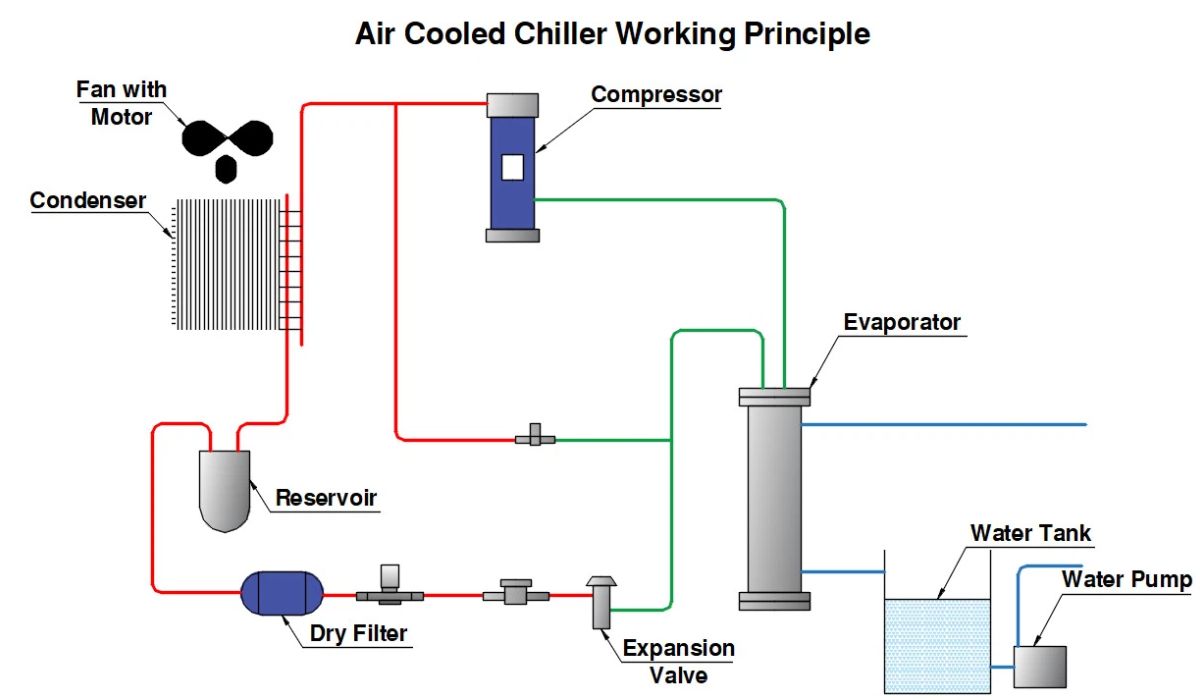

Working Principle

When the air-cooled water chiller is working, the refrigerant absorbs the heat from the cooled object in the evaporator and vaporizes. The compressor continuously draws the gas generated in the evaporator and compresses it into high-temperature and high-pressure vapor. The refrigerant vapor is then sent to the condenser to exchange heat with the air. After releasing heat, it condenses into liquid. The liquid refrigerant is decompressed after passing through the expansion valve. Then it enters the evaporator to absorb the heat of the cooled object and vaporizes again. This heat exchange process is repeated until the industrial water is cooled to the required temperature.

Shandong GRAD Group is a large modern enterprise with over two decades history. Our business started in 1993, with staff of over 2200, we are focus on R&D, production, marketing, installation and maintenance for central air conditioning system and G R P composite material products. We are committed to providing customers with one-stop central air-conditioning and FRP composite material product solutions.

For central air conditioning products, we have production facility covering 450000 sqm, we can offer products for the whole system including chillers, heat pumps, cooling towers, A H U s, F C U s and ventilation products. To better participate international project, we have C T I, C E, A H R I certificates to guarantee our products quality.

For G R P composite material products, we have production facility covering 700000 sqm. With its feature of light weight, high strength, anti-corrosion and long service life, the G R P products are ideal replacement for steel products. We can offer process like vacuum injection, G R P winding, S M C mould pressing, molding pultrusion and hand paste. Based on different process, we can offer clients customized products.

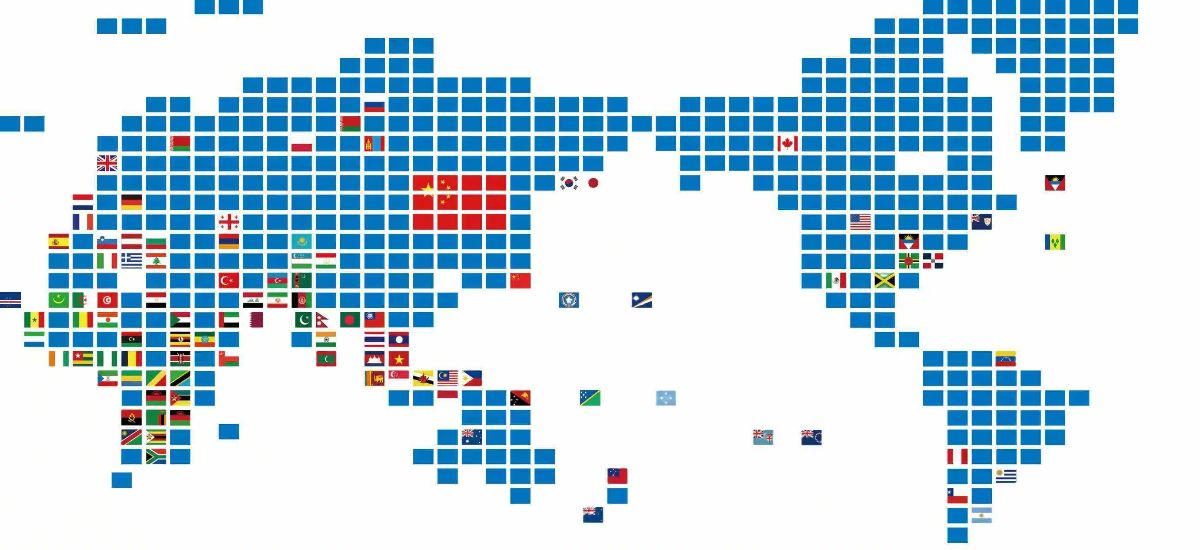

GRAD international business starts in 2009, now its products have been exported to 100 countries and regions.

GRAD, as a flagship enterprise in central air conditioner and G R P composite material products industry, is dedicated to be a one-stop supplier for global purchasing agents.

Why Choose GRAD?

✔ 30+ Years of HVAC Expertise

✔ Strong International Presence (100+ Countries)

✔ Advanced Manufacturing with 500,000 sqm Facility

✔ 1,000+ Patents for Innovative Solutions

✔ Commitment to Quality & Sustainability At GRAD, we strive to create comfortable, efficient, and environmentally friendly climate control systems for a better future. For more information, visit our official website or contact us directly.