Glass Fiber Reinforced Plastic Pipe

Why choose GRAD FRP winding pipe?

1.Top 3 brands and annual output manufacturers.

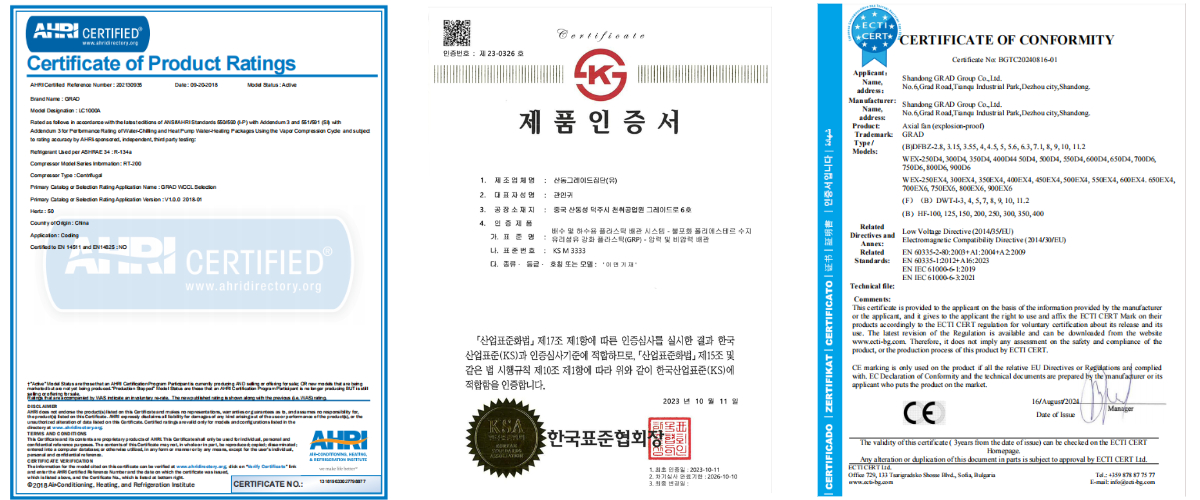

2.Qualified by Korean KS certificate, which is the only one in China.

3.Over 30+ years production experience since 1993.

4.50+ years of lifespan, durable products.

5.China national projects participation experience:

South-to-North Water Diversion Project

Yellow Water to East China Diversion Project

Guizhou Jiayan Water Conservancy Project and Northwest Guizhou Water Supply Project

6.Overseas pipeline project achievements:

Yeosu Water Treatment Plant Project in South Korea

Sewage Pipeline Project in Battambang Province, Cambodia

Indonesia West Kalimantan 2 x 50 MW coal-fired power stations FRP pipe project

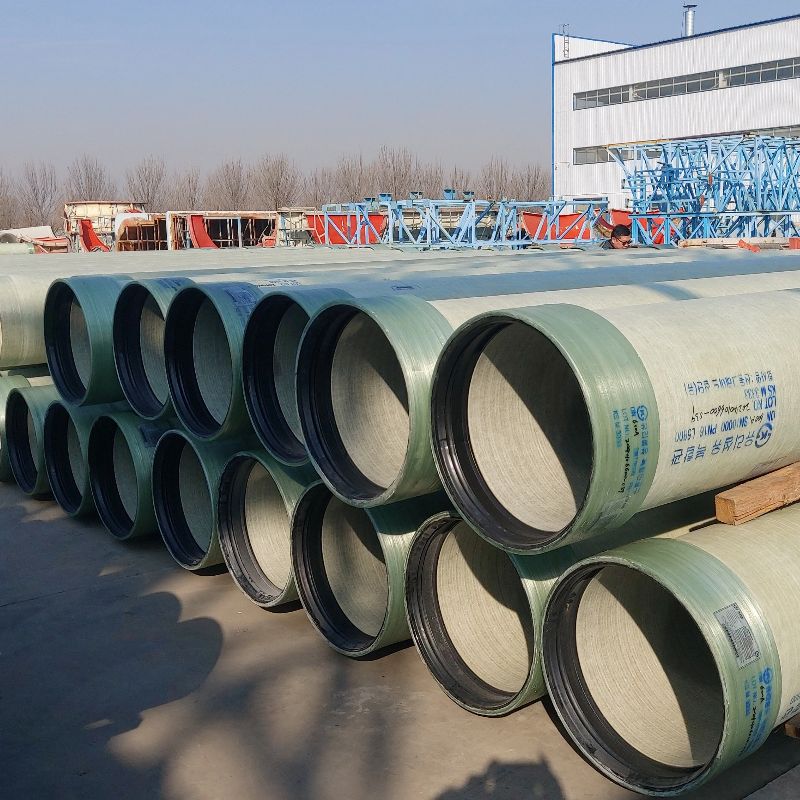

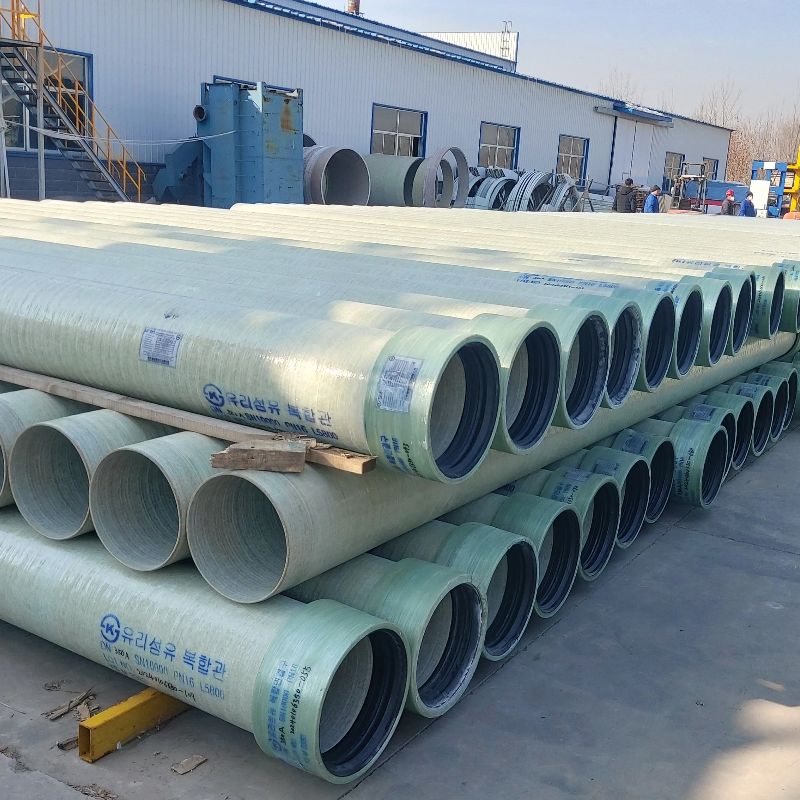

Glass Fiber Reinforced Plastic Pipe

Glass Fiber Reinforced Plastic Pipe are manufactured using the process of Continuance Filament Winding (CFW). Our range of GRP pipe products offer structural strengths and corrosion resistance for optimum performance within high pressure applications. FRP is lightweight, extremely strong, easy to install, and resistant to deterioration.

Application

Application of GRP pipes for underground and aboveground piping systems includes:

Potable water and clean water transportation lines

Main conveyance and network lines for irrigation.

Rainwater and drainage lines.Sewer line

Industrial wastewater lines

Subsea piping, water intake, discharge lines and diffusers.

Piping of chemical plants

Circulation lines of power plants

ipelines of hydroelectric power plants.

Jacking pipe and -relining pipelines

Drinking water storage

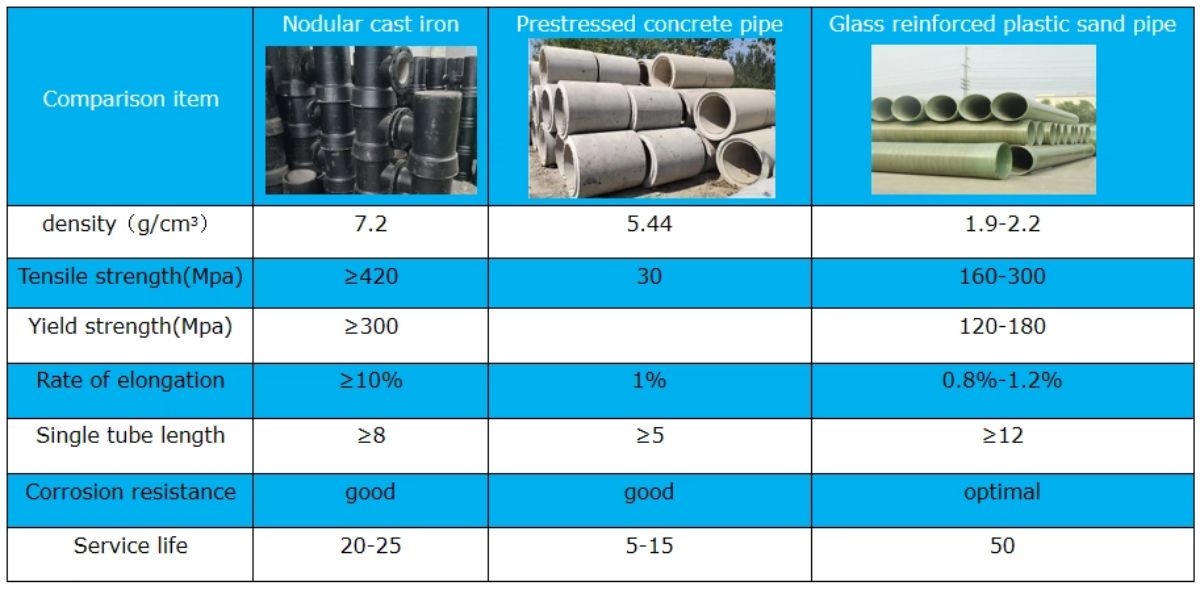

※Long Service Life

Pipes are designed in compliance with the international standards to serve a minimum of 50 years. Operating and maintenance costs are negligibly small. .

※Safe Connections

GRP pipe joints are designed with the flexible connection method, and the sealing is provided by couplings having full-face integrated elastomeric seal.

※Surge Pressure Absorption

Additional pressure increases occurring due to surges are far less when compared with metal pipes. They are designed to absorb 40% of the surge pressure, without increasing the pressure class.

About Us

GRAD sales network covers over 100 countries and regions like America, Australia Indonesia, Malaysia, UAE, Thailand, Nigeria etc and has established branch company in USA, and set up offices in Cambodia and Thailand to make overall layout of global market.

GRAD Group devotes itself to be a central air conditioning customization expert around you and provides you a comprehensive energy solution, GRAD possesses national mechanical and electrical equipment installation Class I qualification and purification equipment installation Class II qualification. GRAD has the overall project contacting ability. It has contracted national class and provincial class technology research projects for many times. The accumulated patents for technolog achievements has passed 110 items. There are more than 300 senior engineers available for central air conditioning design and solution. The 700,000 ㎡ manufacturing base includes the whole central air conditioning series: from chiller to terminal products. The high efficient falling film centrifugal chiller maintains domestic leading position and the large fan wall air handling unit has filled domestic blank and been listed in the national torch plan. GRAD has the national class air conditioning testing center and has passed CNAS certification. The products quality can be well guaranteed. Some of projects gained China Construction Project Luban Prize and National High Quality Project. At the same time, GRAD has established more than 30 offices all over China, such as Beijing, Tianjin, Shenyang, Xi’an, Wuhan, Nanjing, etc. The sales, design, installation and after sales network has covered every corner of China. Moreover, its products have been exported to more than 100 countries.