Cooling Tower Air Conditioning

1.CTI certification

Authoritative certification, exported to the European and American markets

2. Long lifespan

The vacuum intake air duct and pultruded panel are made of fiberglass reinforced plastic, which is of high strength and corrosion resistance

3. Low noise

Patented technology of integral water spray packing, with lower noise

4. Efficient cooling

Integral packing, uniform water distribution and large heat exchange area

5. Easy installation

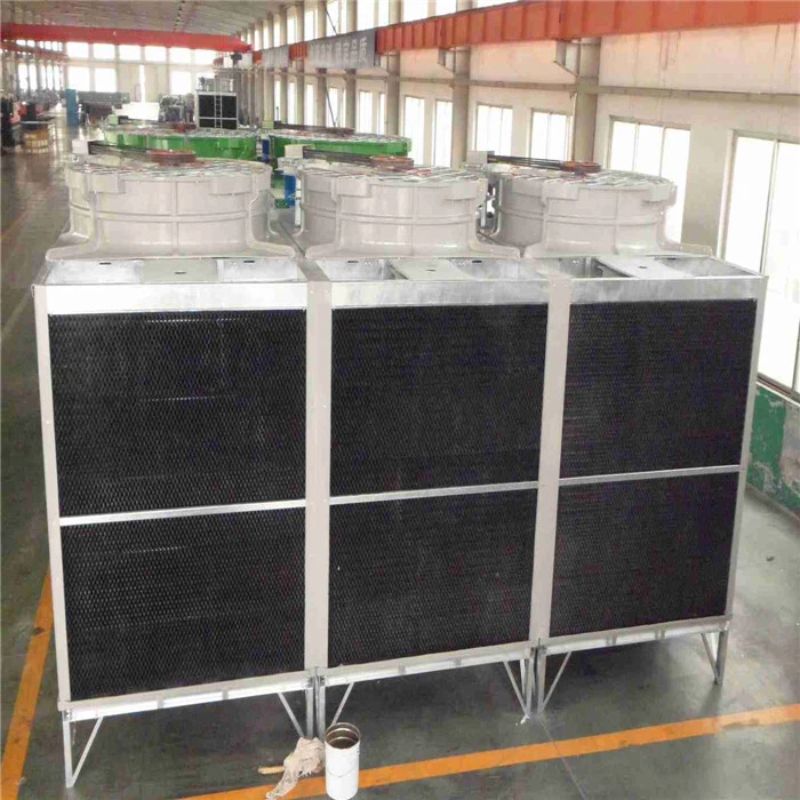

Modular design: Steel parts are welded into blocks before leaving the factory, reducing on-site welding

Cooling Tower Air Conditioning

GRAD Core technology

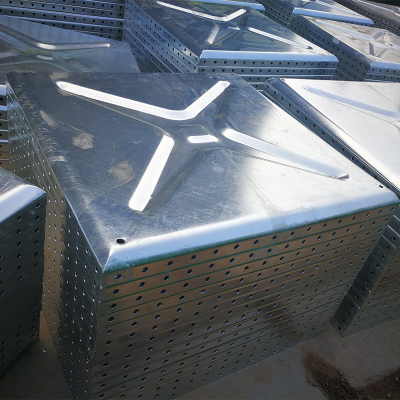

The spray water tray is made by one-time molding process, with no seams as a whole, eliminating dripping and splashing water at the water tray. The frame is formed by one-time bending of hot-dip galvanized steel plates, with C-shaped groove reinforcement design. The fiberglass reinforced plastic air duct is formed by vacuum introduction process, and its strength and toughness are increased by more than 50% compared with the hand lay-up process. All fiberglass reinforced plastic parts have abandoned the original hand lay-up process. The panels are made by pultrusion, the water tanks by molding, and the corners by molding. The overall appearance of the equipment is more aesthetically pleasing. The semi-enclosed water chamber is set up to effectively block debris and prevent direct sunlight from shining on the water chamber, which could cause pollution to the water system by algae, bacteria, etc. The tower body is equipped with fiberglass reinforced plastic (FRP) protective plates, and the outer layer of the protective plates is formed with high-quality imported gel coat, which is resistant to ultraviolet rays and aging, thus extending the service life of the equipment. It adopts a modular design of 100-700 square meters per hour, suitable for connecting multiple towers together. It occupies a small area and is elegant and stylish. Steel parts are welded into blocks before leaving the factory, reducing on-site welding and ensuring the safe operation of the equipment.

Model | Water yield m3/h | Cooling efficient×103 K cal/h | Motor power KW | The fan diameter Φ mm | The tower body lift mH2O | Overall dimensions (mm) | Noise dB(A) | ||||

L | W | H | P | R | T | ||||||

BHD-100 | 100 | 500 | 2.2 | 1768 | 3.5 | 3800 | 2060 | 3350 | 60.1 | 57.4 | 50.0 |

BHD-125 | 125 | 625 | 3 | 1768 | 3.5 | 4200 | 2060 | 3350 | 61.2 | 57.6 | 51.2 |

BHD-150 | 150 | 750 | 3 | 2168 | 3.6 | 4200 | 2460 | 3350 | 61.4 | 57.8 | 51.5 |

BHD-175 | 175 | 875 | 4 | 2168 | 3.6 | 4600 | 2460 | 3350 | 62.3 | 58.1 | 52.9 |

BHD-200 | 200 | 1000 | 4 | 2560 | 3.8 | 4600 | 2860 | 3350 | 62.5 | 58.7 | 53.4 |

BHD-225 | 225 | 1125 | 5.5 | 2560 | 3.9 | 5000 | 2860 | 4000 | 63.1 | 59.3 | 53.8 |

BHD-250 | 250 | 1250 | 5.5 | 2954 | 4.0 | 5000 | 3260 | 4000 | 63.4 | 59.8 | 54.5 |

BHD-300 | 300 | 1500 | 7.5 | 2954 | 4.0 | 5400 | 3260 | 4000 | 64.3 | 60.6 | 55.2 |

BHD-330 | 330 | 1650 | 7.5 | 3340 | 4.2 | 5400 | 3660 | 4000 | 63.9 | 60.4 | 54.7 |

BHD-370 | 370 | 1850 | 11 | 3340 | 4.4 | 5800 | 3660 | 4500 | 64.2 | 60.7 | 55.1 |

BHD-400 | 400 | 2000 | 11 | 3744 | 4.9 | 5800 | 4060 | 4500 | 64.7 | 61.3 | 55.7 |

BHD-450 | 450 | 2250 | 15 | 3744 | 4.9 | 6200 | 4060 | 4500 | 65.3 | 61.4 | 56.1 |

BHD-500 | 500 | 2500 | 15 | 4140 | 5.0 | 6600 | 4460 | 5000 | 65.4 | 61.7 | 56.3 |

BHD-600 | 600 | 3000 | 18.5 | 4140 | 5.3 | 7000 | 4460 | 5000 | 66.1 | 62.4 | 57.1 |

BHD-700 | 700 | 3500 | 18.5 | 4540 | 5.3 | 7400 | 4860 | 5000 | 67.3 | 63.6 | 58.2 |

Technical parameters of BHD series of square cross-flow GRP cooling towers

2. It must be quiet around the cooling tower before determination of noise, the environmental noise should be 10dB (A) or more lower than the noise at the measuring point R under normal work of the tower, otherwise, it should be corrected. Please consult the technical personnel of the company for corrected value.

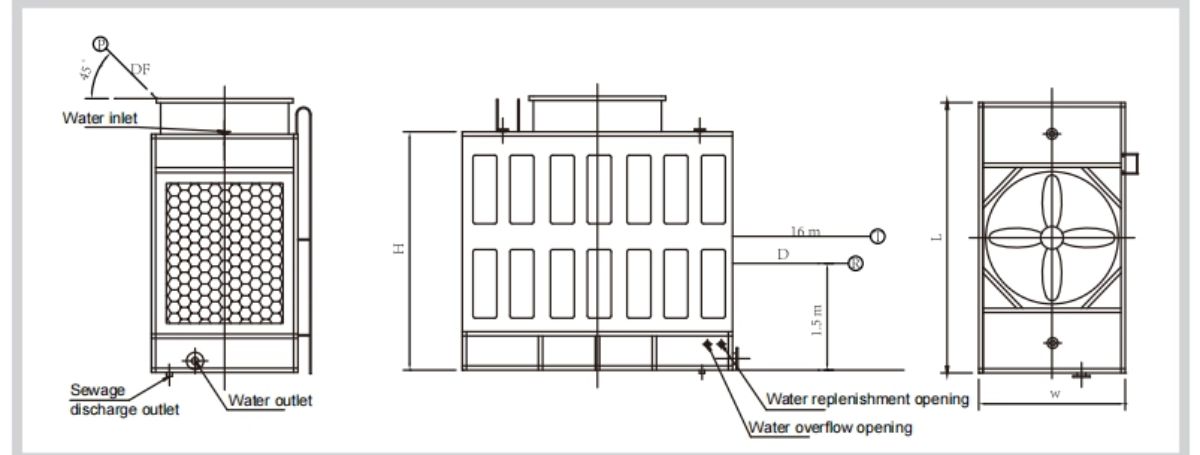

3. DF shown in the figure is the distance of equivalent diameter of the air outlet: 1.5≤DF≤5m.

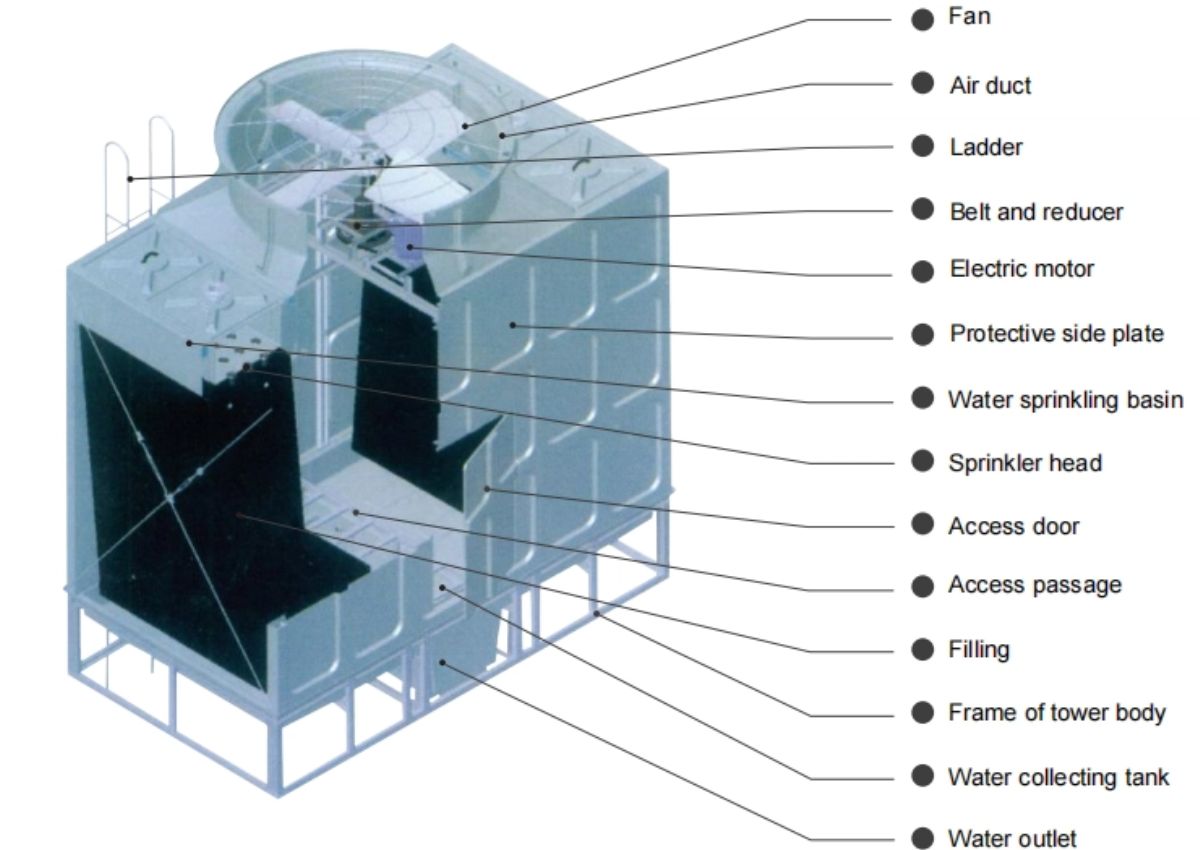

Major components

Electric motor

The motor is the special motor for totally closed cooling towers and it is suitable for continuous operation in a hot-humid environment for a long term with high efficiency, low noise, long service life and high reliability. And also, the domestic or imported motors and corresponding inverters can be equipped according to customer requirements.

Fan

The surface of fan is treated with the electrochemical anticorrosion. The fan passes the balance debugging, has the space warp structure with large chord angle, and has the characteristics of large air volume, high efficiency, static operation and corrosion resistance.

Air duct

The air duct is an arc transition made of high quality GRP composite material with smooth appearance, which can effectively reduce the wind resistance and provide a good air flow environment.

Sprinkler head

The square sprinkler head is used. The whole spray surface is square, and there is no dead angle or no overlap in the spraying. The cooling water is sent evenly to every corner of the filling. The sprinkler head has the characteristics of long service life, no blockage and high efficiency.

Filling

The padding is the combination of high quality modified PVC trapezoid blocks with self-reinforcing air inlet surface and water collecting surface, good surface hydrophilicity, large heat dissipation area, small wind resistance, high cooling efficiency and corrosion resistance.

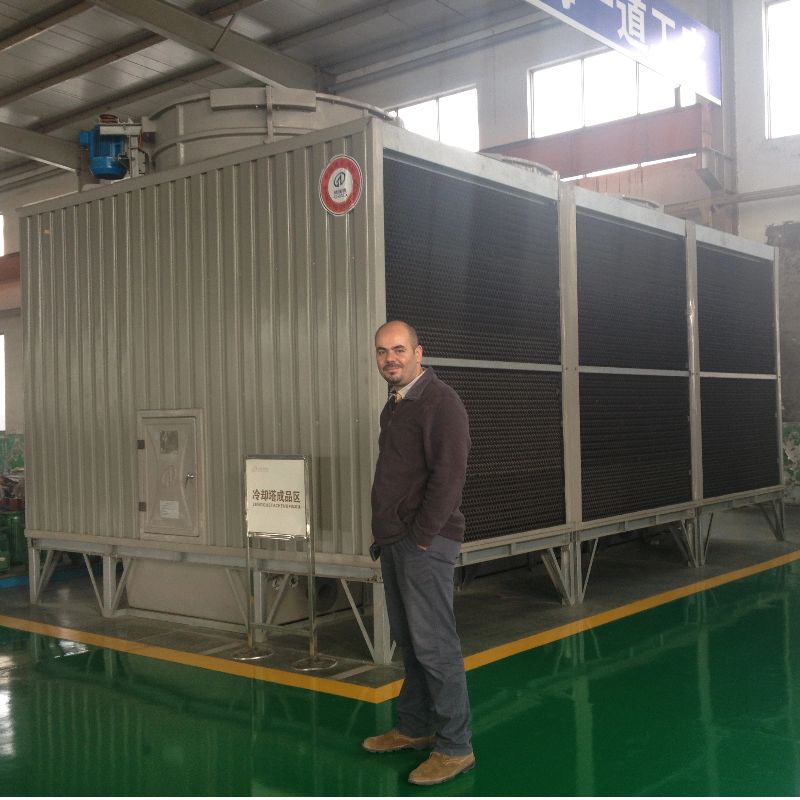

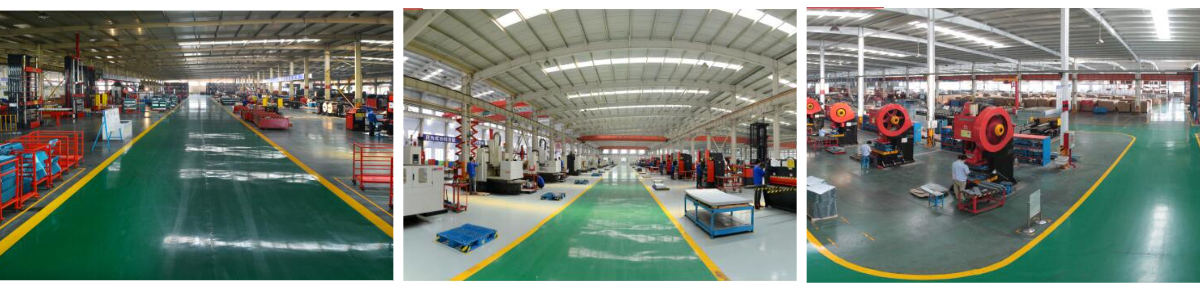

Establised in 1993, GRAD Group covers an area of 1.15 million square meters and has more than 2,000 employees, with an annual output value of nearly 4 billion yuan. GRAD Group's main business: central air conditioning chiller and terminal products, FRP water tank, FRP winding pipe, FRP storage tank, wind turbine cabin cover, environmental protection equipment, and other more than 130 varieties. GRAD Group is the pillar enterprise of the “Dezhou Central Air-Conditioning City” named by the China Refrigeration and Air-Conditioning Industry Association. It ranks the top 10 among central air-conditioning enterprises in the country, The top 3 composite material enterprises,and gets the first-class qualification for the installation of national electromechanical equipment and the second-class qualification for air purification engineering. GRAD Group can undertake central air conditioning engineering, purification engineering construction.