Fiberglass Cooling Tower

1.CTI certification

Authoritative certification, exported to the European and American markets

2. Long lifespan

The vacuum intake air duct and pultruded panel are made of fiberglass reinforced plastic, which is of high strength and corrosion resistance

3. Low noise

Patented technology of integral water spray packing, with lower noise

4. Efficient cooling

Integral packing, uniform water distribution and large heat exchange area

5. Easy installation

Modular design: Steel parts are welded into blocks before leaving the factory, reducing on-site welding

Fiberglass Cooling Tower

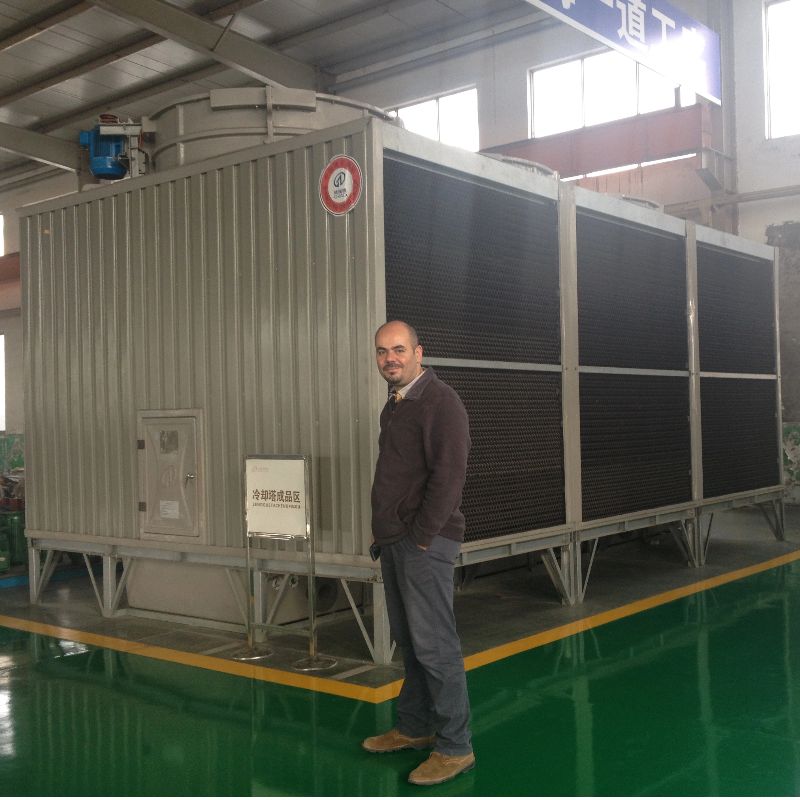

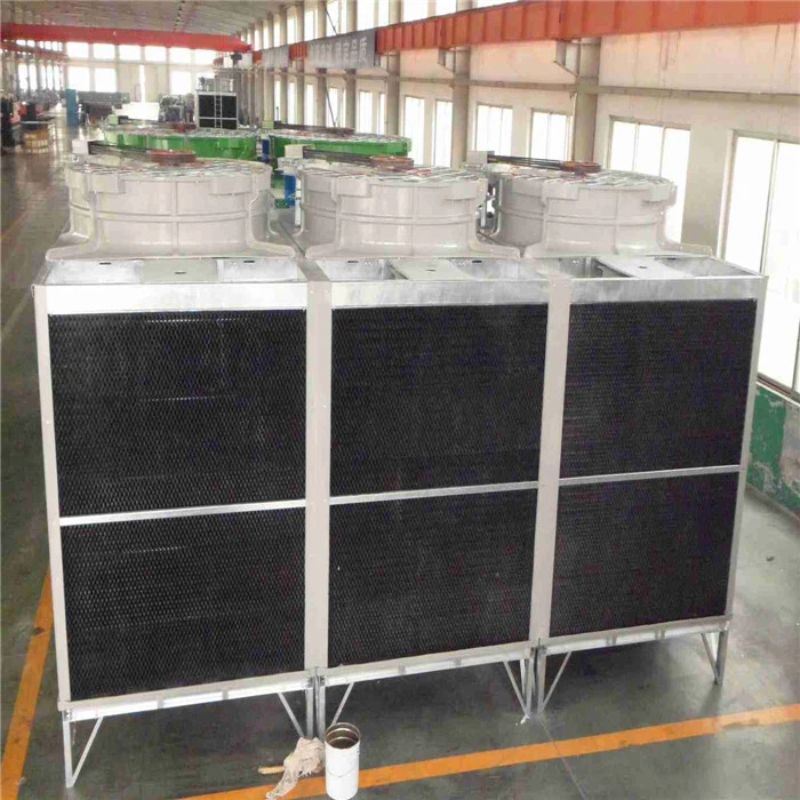

Special Design, Special Quality

Fiberglass cross-flow cooling towers are optimized in design of their structure and process on the basis of the traditional square GRP cooling tower. The function of each inner part is reasonably selected. All components and materials are strictly selected and tested to ensure a long service life and reliable operation. The unique excellent mechanized process improvement provides reliable guarantee for high quality of the cooling tower and effectively reduces the weight of the tower to make the BHD series of square counter-flow GRP cooling towers with the characteristics of small volume, light weight, high efficiency, durability and stable operation. At the same time, the cooling towers can be equipped with a new frequency conversion device to realize automatic regulation of fan speed with cooling water temperature under different temperature conditions and different load conditions, so as to achieve the purpose of energy saving and noise reduction, and save equipment operation cost for users.

Cooling: The cooling tower achieves heat dissipation by spraying high-temperature water or other liquids onto the packing layer, utilizing the heat exchange between water and air, thereby reducing the liquid's temperature to the set range.

Realize recycling: The cooling tower conveys the dissipated water back to the equipment for recycling, thereby reducing water consumption and improving the utilization efficiency of water resources.

Protecting equipment: In industrial production, some equipment needs to operate in high-temperature environments. However, high temperatures can have adverse effects on the equipment. Therefore, cooling towers are required to reduce the temperature of the equipment to the normal range to ensure its normal operation.

Energy conservation: Cooling towers can reduce the temperature of liquids to the set range by utilizing natural wind or forced convection through fans, thereby reducing energy consumption and improving energy utilization efficiency.

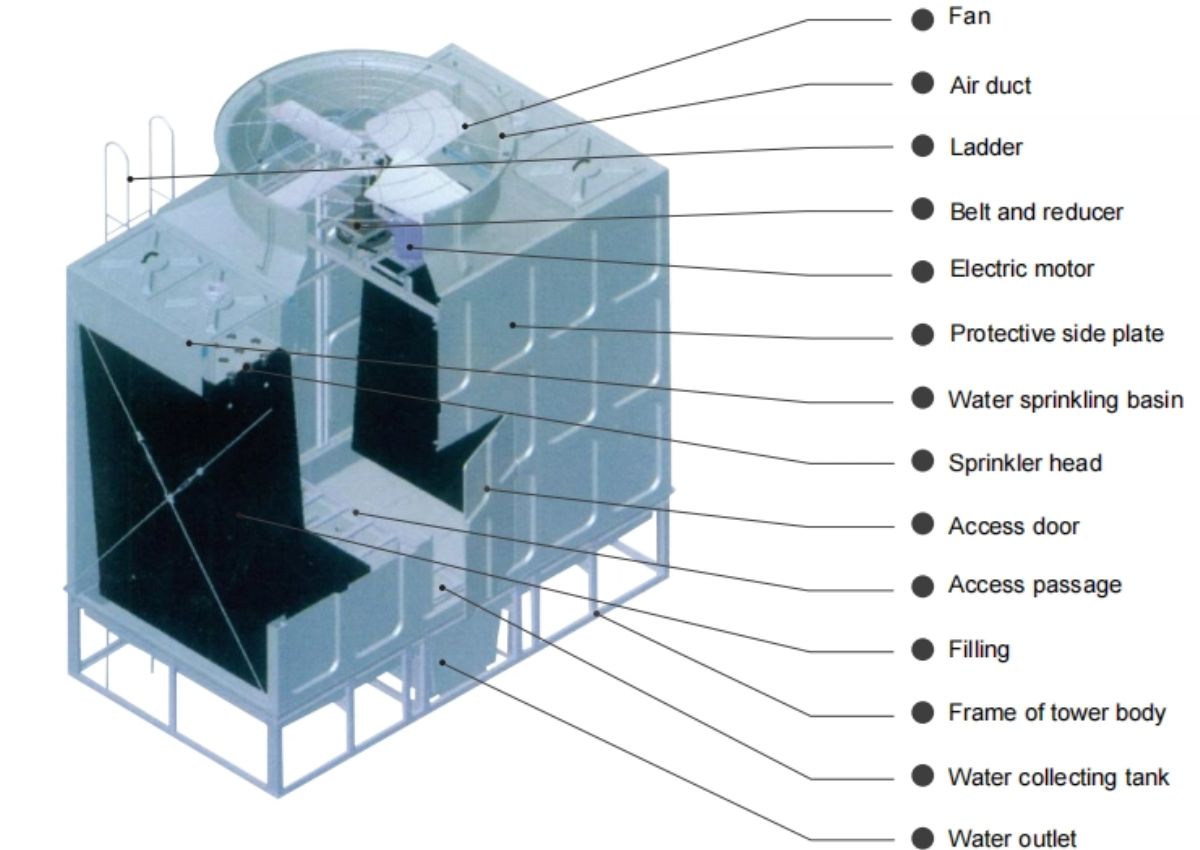

Major components

Electric motor

The motor is the special motor for totally closed cooling towers and it is suitable for continuous operation in a hot-humid environment for a long term with high efficiency, low noise, long service life and high reliability. And also, the domestic or imported motors and corresponding inverters can be equipped according to customer requirements.

Fan

The surface of fan is treated with the electrochemical anticorrosion. The fan passes the balance debugging, has the space warp structure with large chord angle, and has the characteristics of large air volume, high efficiency, static operation and corrosion resistance.

Filling

The padding is the combination of high quality modified PVC trapezoid blocks with self-reinforcing air inlet surface and water collecting surface, good surface hydrophilicity, large heat dissipation area, small wind resistance, high cooling efficiency and corrosion resistance.

Frame

The frame adopts high strength steel parts with the surface treated by anticorrosion treatment. It has features of corrosion resistant, light weight and easy assembly

Model | Water yield m3/h | Cooling efficient×103 K cal/h | Motor power KW | The fan diameter Φ mm | The tower body lift mH2O | Overall dimensions (mm) | Noise dB(A) | ||||

L | W | H | P | R | T | ||||||

BHD-100 | 100 | 500 | 2.2 | 1768 | 3.5 | 3800 | 2060 | 3350 | 60.1 | 57.4 | 50.0 |

BHD-125 | 125 | 625 | 3 | 1768 | 3.5 | 4200 | 2060 | 3350 | 61.2 | 57.6 | 51.2 |

BHD-150 | 150 | 750 | 3 | 2168 | 3.6 | 4200 | 2460 | 3350 | 61.4 | 57.8 | 51.5 |

BHD-175 | 175 | 875 | 4 | 2168 | 3.6 | 4600 | 2460 | 3350 | 62.3 | 58.1 | 52.9 |

BHD-200 | 200 | 1000 | 4 | 2560 | 3.8 | 4600 | 2860 | 3350 | 62.5 | 58.7 | 53.4 |

BHD-225 | 225 | 1125 | 5.5 | 2560 | 3.9 | 5000 | 2860 | 4000 | 63.1 | 59.3 | 53.8 |

BHD-250 | 250 | 1250 | 5.5 | 2954 | 4.0 | 5000 | 3260 | 4000 | 63.4 | 59.8 | 54.5 |

BHD-300 | 300 | 1500 | 7.5 | 2954 | 4.0 | 5400 | 3260 | 4000 | 64.3 | 60.6 | 55.2 |

BHD-330 | 330 | 1650 | 7.5 | 3340 | 4.2 | 5400 | 3660 | 4000 | 63.9 | 60.4 | 54.7 |

BHD-370 | 370 | 1850 | 11 | 3340 | 4.4 | 5800 | 3660 | 4500 | 64.2 | 60.7 | 55.1 |

BHD-400 | 400 | 2000 | 11 | 3744 | 4.9 | 5800 | 4060 | 4500 | 64.7 | 61.3 | 55.7 |

BHD-450 | 450 | 2250 | 15 | 3744 | 4.9 | 6200 | 4060 | 4500 | 65.3 | 61.4 | 56.1 |

BHD-500 | 500 | 2500 | 15 | 4140 | 5.0 | 6600 | 4460 | 5000 | 65.4 | 61.7 | 56.3 |

BHD-600 | 600 | 3000 | 18.5 | 4140 | 5.3 | 7000 | 4460 | 5000 | 66.1 | 62.4 | 57.1 |

BHD-700 | 700 | 3500 | 18.5 | 4540 | 5.3 | 7400 | 4860 | 5000 | 67.3 | 63.6 | 58.2 |

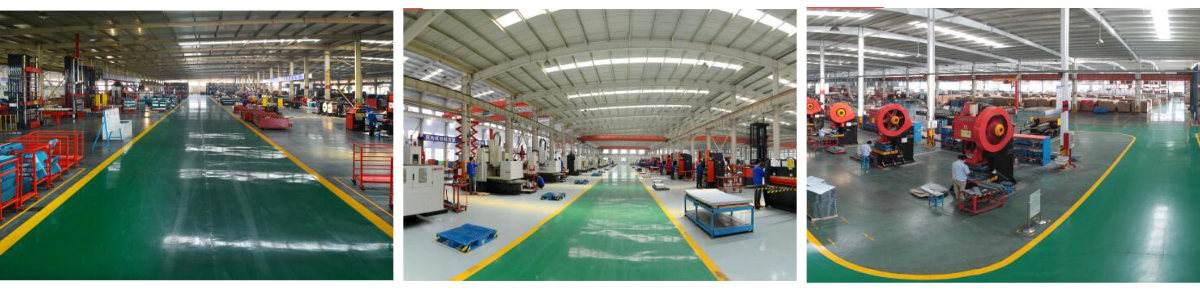

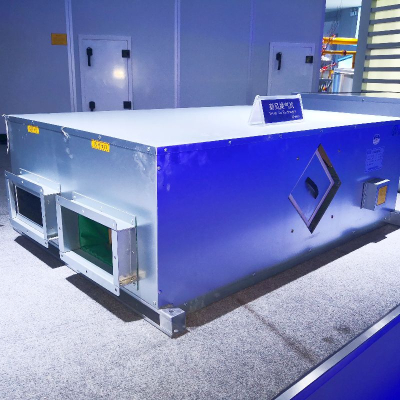

About us

GRAD Group devotes itself to be a central air conditioning customization expert around you and provides you a comprehensive energy solution, GRAD possesses national mechanical and electrical equipment installation Class I qualification and purification equipment installation Class II qualification. GRAD has the overall project contacting ability. It has contracted national class and provincial class technology research projects for many times. The accumulated patents for technolog achievements has passed 110 items. There are more than 300 senior engineers available for central air conditioning design and solution. The 700,000 ㎡ manufacturing base includes the whole central air conditioning series: from chiller to terminal products. The high efficient falling film centrifugal chiller maintains domestic leading position and the large fan wall air handling unit has filled domestic blank and been listed in the national torch plan. GRAD has the national class air conditioning testing center and has passed CNAS certification. The products quality can be well guaranteed. Some of projects gained China Construction Project Luban Prize and National High Quality Project. At the same time, GRAD has established more than 30 offices all over China, such as Beijing, Tianjin, Shenyang, Xi’an, Wuhan, Nanjing, etc. The sales, design, installation and after sales network has covered every corner of China. Moreover, its products have been exported to more than 100 countries.