Cooling Tower Air Conditioning System

1.CTI certification

Authoritative certification, exported to the European and American markets

2. Long lifespan

The vacuum intake air duct and pultruded panel are made of fiberglass reinforced plastic, which is of high strength and corrosion resistance

3. Low noise

Patented technology of integral water spray packing, with lower noise

4. Efficient cooling

Integral packing, uniform water distribution and large heat exchange area

5. Easy installation

Modular design: Steel parts are welded into blocks before leaving the factory, reducing on-site welding

Cooling Tower Air Conditioning System

The main functions of cooling towers are as follows

Cooling: The cooling tower achieves heat dissipation by spraying high-temperature water or other liquids onto the packing layer, utilizing the heat exchange between water and air, thereby reducing the liquid's temperature to the set range.

Realize recycling: The cooling tower conveys the dissipated water back to the equipment for recycling, thereby reducing water consumption and improving the utilization efficiency of water resources.

Protecting equipment: In industrial production, some equipment needs to operate in high-temperature environments. However, high temperatures can have adverse effects on the equipment. Therefore, cooling towers are required to reduce the temperature of the equipment to the normal range to ensure its normal operation.

Energy conservation: Cooling towers can reduce the temperature of liquids to the set range by utilizing natural wind or forced convection through fans, thereby reducing energy consumption and improving energy utilization efficiency.

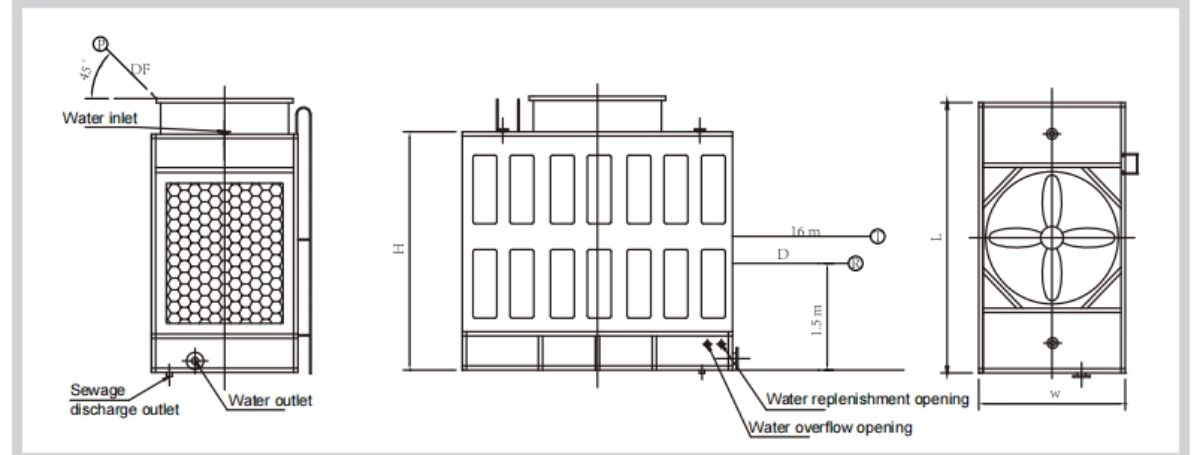

Technical parameters of BHD series of square cross-flow GRP cooling towers

1. The measuring points (R) and (T) are all in the direction of air inlet of the cooling tower. The equivalent diameter D=1.13 W L, among which, L and W are respectively the side length of the cooling tower.

2. It must be quiet around the cooling tower before determination of noise, the environmental noise should be 10dB (A) or more lower than the noise at the measuring point R under normal work of the tower, otherwise, it should be corrected. Please consult the technical personnel of the company for corrected value.

3. DF shown in the figure is the distance of equivalent diameter of the air outlet: 1.5≤DF≤5m.

Application

The Cross Flow cooling towers produced by GRAD have all passed the performance tests of the American Refrigeration Institute and obtained the CTI certification certificate. It can be widely applied in shopping malls, hotels, schools, libraries, office buildings, exhibition halls, airports, stadiums, subways, high-speed railways and other places with high requirements for noise control, providing supporting services for refrigeration chillers.

Technical and specification parameters of BHD-100~BHD- 700

Model | Water yield m3/h | Cooling efficient×103 K cal/h | Motor power KW | The fan diameter Φ mm | The tower body lift mH2O | Overall dimensions (mm) | Noise dB(A) | ||||

L | W | H | P | R | T | ||||||

BHD-100 | 100 | 500 | 2.2 | 1768 | 3.5 | 3800 | 2060 | 3350 | 60.1 | 57.4 | 50.0 |

BHD-125 | 125 | 625 | 3 | 1768 | 3.5 | 4200 | 2060 | 3350 | 61.2 | 57.6 | 51.2 |

BHD-150 | 150 | 750 | 3 | 2168 | 3.6 | 4200 | 2460 | 3350 | 61.4 | 57.8 | 51.5 |

BHD-175 | 175 | 875 | 4 | 2168 | 3.6 | 4600 | 2460 | 3350 | 62.3 | 58.1 | 52.9 |

BHD-200 | 200 | 1000 | 4 | 2560 | 3.8 | 4600 | 2860 | 3350 | 62.5 | 58.7 | 53.4 |

BHD-225 | 225 | 1125 | 5.5 | 2560 | 3.9 | 5000 | 2860 | 4000 | 63.1 | 59.3 | 53.8 |

BHD-250 | 250 | 1250 | 5.5 | 2954 | 4.0 | 5000 | 3260 | 4000 | 63.4 | 59.8 | 54.5 |

BHD-300 | 300 | 1500 | 7.5 | 2954 | 4.0 | 5400 | 3260 | 4000 | 64.3 | 60.6 | 55.2 |

BHD-330 | 330 | 1650 | 7.5 | 3340 | 4.2 | 5400 | 3660 | 4000 | 63.9 | 60.4 | 54.7 |

BHD-370 | 370 | 1850 | 11 | 3340 | 4.4 | 5800 | 3660 | 4500 | 64.2 | 60.7 | 55.1 |

BHD-400 | 400 | 2000 | 11 | 3744 | 4.9 | 5800 | 4060 | 4500 | 64.7 | 61.3 | 55.7 |

BHD-450 | 450 | 2250 | 15 | 3744 | 4.9 | 6200 | 4060 | 4500 | 65.3 | 61.4 | 56.1 |

BHD-500 | 500 | 2500 | 15 | 4140 | 5.0 | 6600 | 4460 | 5000 | 65.4 | 61.7 | 56.3 |

BHD-600 | 600 | 3000 | 18.5 | 4140 | 5.3 | 7000 | 4460 | 5000 | 66.1 | 62.4 | 57.1 |

BHD-700 | 700 | 3500 | 18.5 | 4540 | 5.3 | 7400 | 4860 | 5000 | 67.3 | 63.6 | 58.2 |

Note:

1. Test the cooling efficiency under the working conditions of the water inlet temperature of 37°C, water outlet temperature of 32°C, ambient wet bulb temperature of 28°C and atmospheric pressure of 99.4kPa.

2.The indicated noise value is the measured value at a running frequency of 50Hz. Please see the frequency comparison table for actual running noise. (The data is subject to change without prior notice)

About us

Establised in 1993, GRAD Group covers an area of 1.15 million square meters and has more than 2,000 employees, with an annual output value of nearly 4 billion yuan. GRAD Group's main business: central air conditioning chiller and terminal products, FRP water tank, FRP winding pipe, FRP storage tank, wind turbine cabin cover, environmental protection equipment, and other more than 130 varieties. GRAD Group is the pillar enterprise of the “Dezhou Central Air-Conditioning City” named by the China Refrigeration and Air-Conditioning Industry Association. It ranks the top 10 among central air-conditioning enterprises in the country, The top 3 composite material enterprises,and gets the first-class qualification for the installation of national electromechanical equipment and the second-class qualification for air purification engineering. GRAD Group can undertake central air conditioning engineering, purification engineering construction.

GRAD sales network covers over 100 countries and regions like America, Australia Indonesia, Malaysia, UAE, Thailand, Nigeria etc and has established branch company in USA, and set up offices in Cambodia and Thailand to make overall layout of global market.