Fan Coil HVAC System

Leading in technology

Six provincial-level enterprise technology centers and nearly 500 patent technology achievements participated Seventeen national and industry standards have been formulated

The entire industrial chain

Solar energy + ventilation and air conditioning, cooling, heating, hot water, purification, ventilation Civil air defense, providing one-stop services covering the entire industrial chain from the mainframe to the terminal

Quality assurance

National-level comprehensive performance testing base for refrigeration and air conditioning, passed CNAS and GMPI certification, a testament to the quality of over 10,000 projects

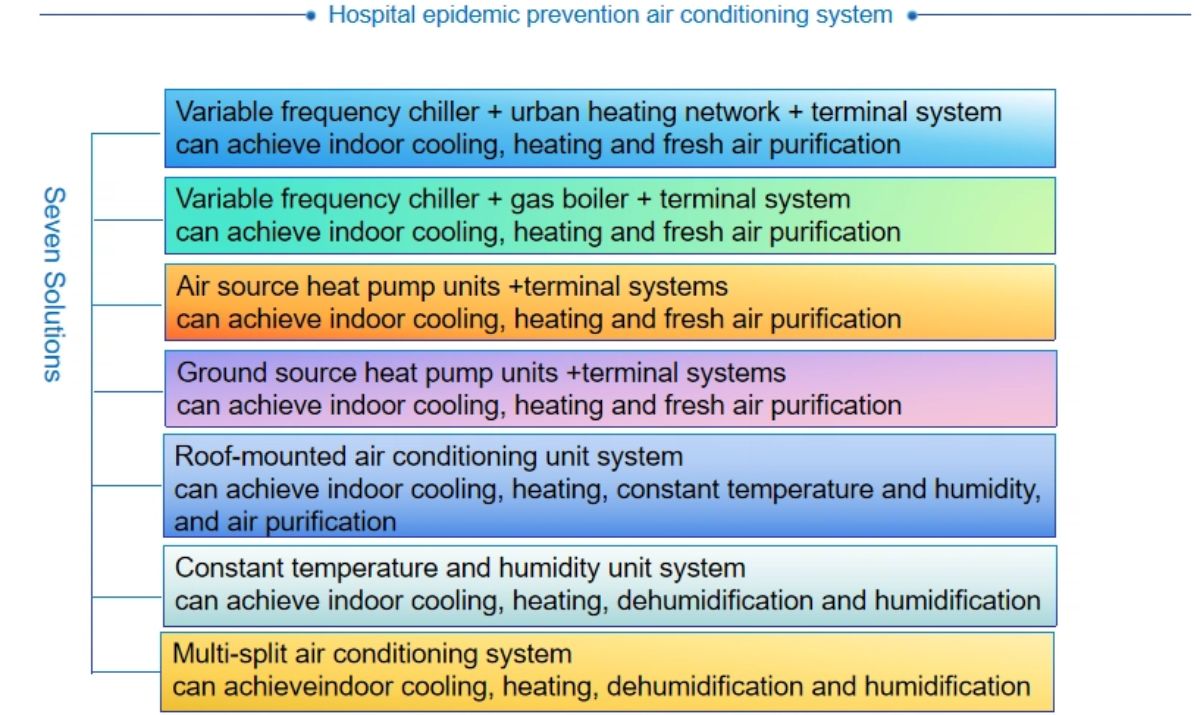

Hospital epidemic prevention air conditioning system

The epidemic prevention air conditioning system of GRAD Hospital is designed in response to the huge demand for epidemic prevention ventilation and air conditioning in the three major systems of new construction, renovation and maintenance. According to the different environmental and air conditioning requirements of different functional areas in comprehensive hospitals, it follows the model of "three zones, two belts and three channels" for the separation of medical staff and patients, and the separation of clean and dirty areas. It is an integrated application solution developed by a research and development team of over a hundred people. Be able to quickly transform general wards into infectious disease wards during the epidemic.

We can provide

1. New hospital epidemic prevention air conditioning system solution

2. Maintenance solutions for the current epidemic prevention air conditioning systems in hospitals

3. Renovation solutions for the existing hospital's epidemic prevention air conditioning system

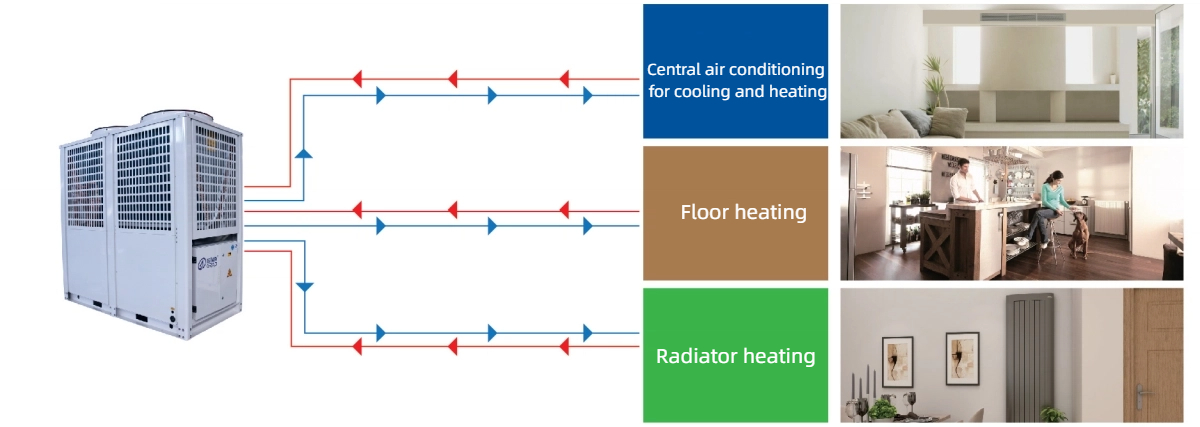

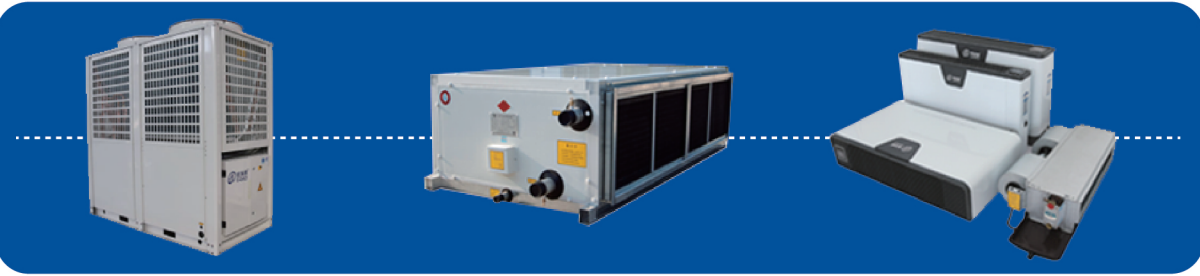

★3、Air source heat pump units +terminal systems

■Applicable places

Generally, small-scale specialized hospitals, postpartum care centers, and medical and elderly care integration projects.

■Function

It can achieve indoor cooling, heating and fresh air purification

■ Main products include

1) The cold and heat sources adopt Grede air source heat pump units with multi-module combinations.

2) For the air conditioning terminal, based on the building structure and functional requirements, fresh air purification air handling units, fan coil units, and medium-efficiency filters or disinfection devices at the return air outlets can be selected.

The entire unit of this system adopts a modular design, allowing for the combination of 16 modules. The maximum capacity of the system can reach 2080KW. There is no need to build a machine room, and it can achieve cooling or heating throughout the year. Therefore, there is no need to be equipped with other heat sources. Moreover, the terminal forms are diverse, and one machine can be used for multiple purposes. It can be applied to radiator, floor radiant, central air conditioning cooling and heating. In addition, this system and its core products also have the following features:

Low ambient temperature air source heat pump units can operate efficiently in an ambient temperature range of -30°C to 43°C, with a maximum water outlet temperature of 60° C. They come in various terminal forms and are suitable for radiator, floor radiant, central air conditioning cooling and heating.

2) National patent intelligent defrosting technology, accurately measuring frost, quickly defrosting, significantly reducing defrosting frequency and greatly shortening defrosting time.

3) Equipped with a self-developed NB-IoT remote intelligent control module for the Internet of Things, it can be operated via a mobile phone APP, eliminating the need for dedicated personnel to stand by. It offers fault early warning prompts and online diagnosis.

4) The energy efficiency of the fan coil unit exceeds the national standard by more than 15%, the noise is 1-2dB(A) lower than the national standard, and it has a wide range of air volumes, with a maximum air output of 3400 square meters per hour.

Application cases of Hospital epidemic prevention Air Conditioning systems

About us

Shandong GRAD Group is a large modern enterprise with over two decades history. Our business started in 1993, with staff of over 2200, we are focus on R&D, production, marketing, installation and maintenance for central air conditioning system and G R P composite material products. We are committed to providing customers with one-stop central air-conditioning and FRP composite material product solutions.

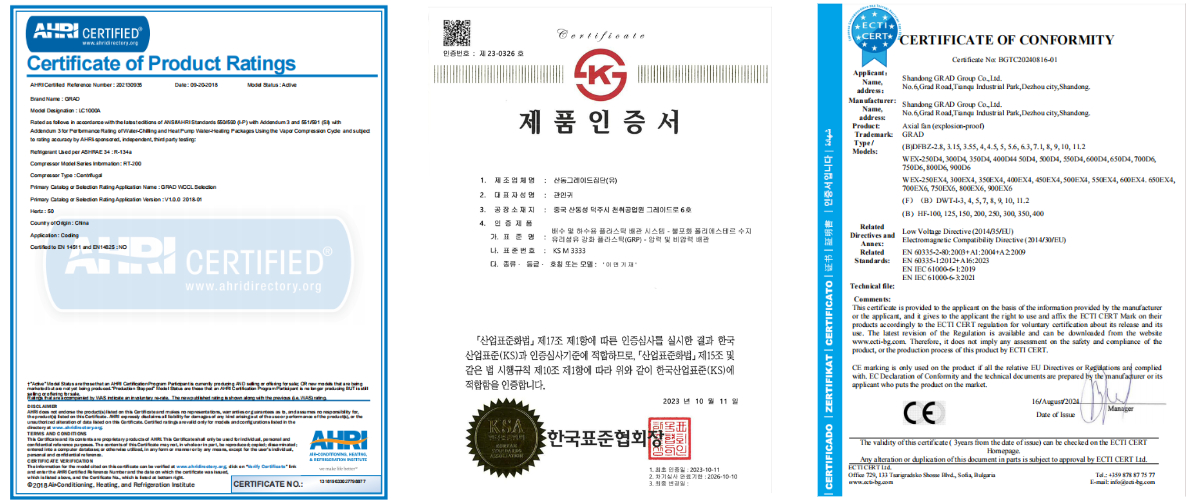

For central air conditioning products, we have production facility covering 450000 sqm, we can offer products for the whole system including chillers, heat pumps, cooling towers, A H U s, F C U s and ventilation products. To better participate international project, we have C T I, C E, A H R I certificates to guarantee our products quality.

For G R P composite material products, we have production facility covering 700000 sqm. With its feature of light weight, high strength, anti-corrosion and long service life, the G R P products are ideal replacement for steel products. We can offer process like vacuum injection, G R P winding, S M C mould pressing, molding pultrusion and hand paste. Based on different process, we can offer clients customized products.

GRAD international business starts in 2009, now its products have been exported to 100 countries and regions.