Cooling Tower

1. Environmentally friendly and energy-saving

Closed-loop fluid circulation reduces scaling and clogging, saving energy by up to 95%

2. Professional customization

National-level cooling tower testing center and designated performance testing base, meeting customers' customized requirements

3. Efficient cooling

The secondary packing design and serpentine corrugated joint heat exchanger increase the heat exchange area by 15% per meter

4. Quality Assurance

The main components are matched with first-line brands at home and abroad

5. Easy installation

Modular design reduces on-site welding

Cooling Tower

The main functions of cooling towers are as follows

Cooling: The cooling tower achieves heat dissipation by spraying high-temperature water or other liquids onto the packing layer, utilizing the heat exchange between water and air, thereby reducing the liquid's temperature to the set range.

Realize recycling: The cooling tower conveys the dissipated water back to the equipment for recycling, thereby reducing water consumption and improving the utilization efficiency of water resources.

Protecting equipment: In industrial production, some equipment needs to operate in high-temperature environments. However, high temperatures can have adverse effects on the equipment. Therefore, cooling towers are required to reduce the temperature of the equipment to the normal range to ensure its normal operation.

Energy conservation: Cooling towers can reduce the temperature of liquids to the set range by utilizing natural wind or forced convection through fans, thereby reducing energy consumption and improving energy utilization efficiency.

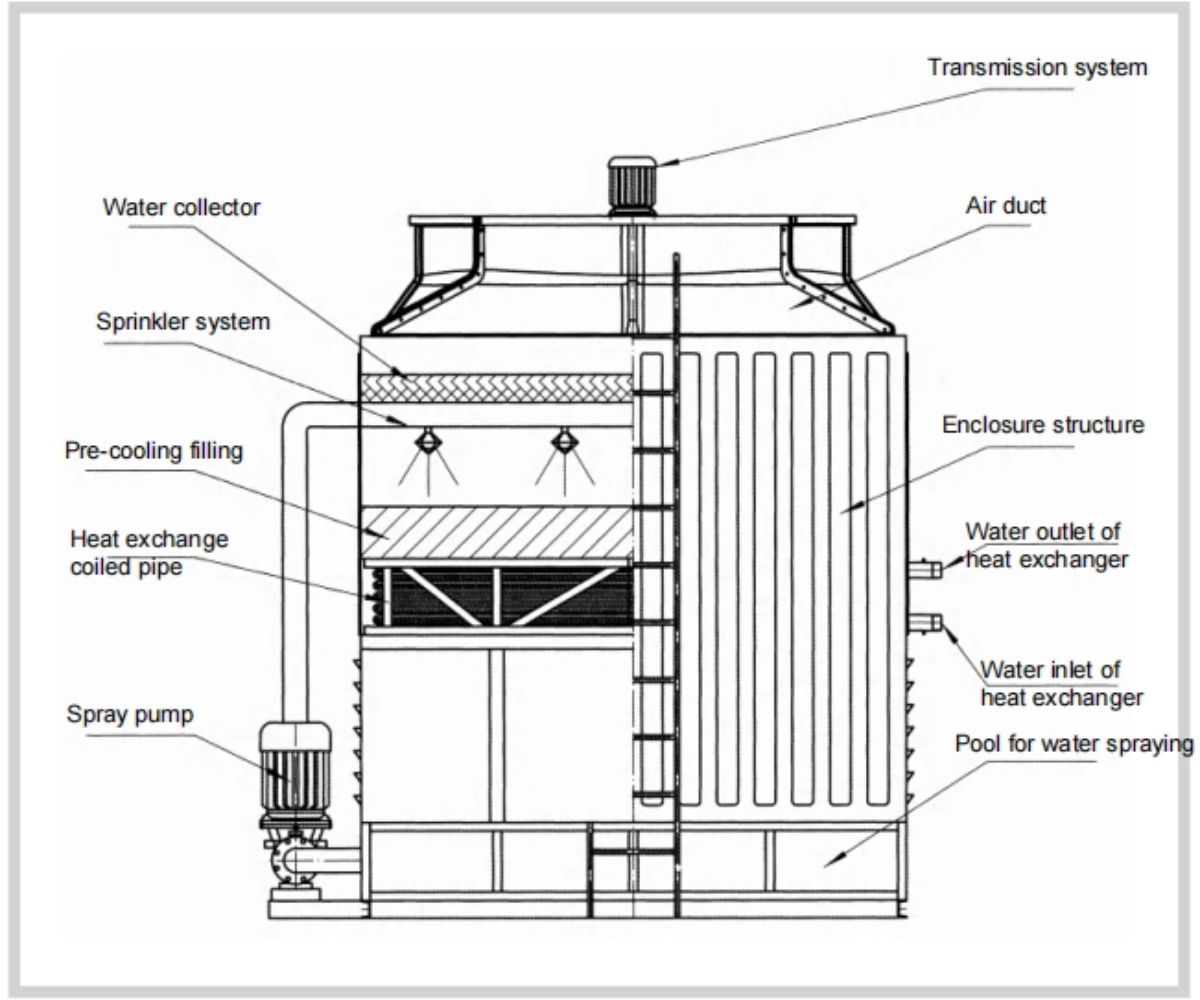

Working principle of FBP series Closed Cooling Tower

The cold fluid flows through the coiled pipe in the closed cooling tower to conduct heat to the wall of coiled pipe; the fan at top of the tower conducts air-pumping operation. The outer-circulation spray water and refresh air taken in by the fan fully come into contact in the tower to exchange latent heat and sensible heat, and make the spray water temperature reduced. The spray water of lower temperature can form water film in coil pipe wall to absorb the heat of the coil pipe wall and thus take away the heat carrying of the medium to achieve the purpose of cooling. The pre-cooling filling in the tower helps to further cool the outer circulation. In the process of heat exchange, the heat carrying medium in the coiled pipe will maintain its original quality characteristics because it does not directly contact with the air and will not be polluted, concentrated, diluted and volatilized. In addition to a small amount of evaporation loss, the spray water outside the coiled pipe comes together at the bottom of the tower and circulates for use. In the process of heat exchange, the heat carrying medium in the coiled pipe will maintain its original quality characteristics because it does not directly contact with the air and will not be polluted, concentrated, diluted and volatilized. In addition to a small amount of evaporation loss, the spray water outside the coiled pipe comes together at the bottom of the tower and circulates for use

Model | Motor power KW | The fan diameter mm | Spray pump power KW | Spray flow m3/h | Pressure drop of the coil K Pa | Own weight Kg | Operating weight Kg | Overall dimensions A×B×H (mm) |

FBP-15 | 1.1 | 900 | 0.75 | 22 | 10 | 920 | 1830 | 1400×1400×2900 |

FBP-20 | 1.5 | 1200 | 0.75 | 34 | 15 | 1220 | 2560 | 1600×1600×3370 |

FBP-30 | 2.2 | 1400 | 1.1 | 45 | 25 | 1460 | 3066 | 2000×2000×3595 |

FBP-40 | 3 | 1500 | 1.5 | 60 | 30 | 1620 | 3402 | 2400×2400×3740 |

FBP-50 | 4 | 1768 | 1.5 | 60 | 45 | 1780 | 3740 | 2580×2580×3915 |

FBP-65 | 5.5 | 2360 | 3 | 118 | 60 | 2120 | 4450 | 3120×3120×4040 |

FBP-80 | 5.5 | 2560 | 3 | 118 | 75 | 2480 | 4960 | 3420×3420×4220 |

FBP-100 | 7.5 | 2954 | 4 | 180 | 15 | 2920 | 5840 | 3900×3900×4525 |

FBP-125 | 11 | 3340 | 5.5 | 217 | 20 | 3220 | 6440 | 4260×4260×4760 |

FBP-150 | 5.5×2 | 2560×2 | 3×2 | 118×2 | 75 | 4960 | 9920 | 6790×3420×4220 |

FBP-200 | 7.5×2 | 2954×2 | 4×2 | 180×2 | 15 | 5840 | 11680 | 7750×3900×4525 |

FBP-250 | 11×2 | 3340×2 | 5.5×2 | 217×2 | 20 | 6440 | 12880 | 8470×4260×4760 |

FBP-300 | 7.5×3 | 2954×3 | 4×3 | 180×3 | 15 | 8760 | 17520 | 11600×3900×4525 |

FBP-375 | 11×3 | 3340×3 | 5.5×3 | 217×3 | 20 | 9660 | 19320 | 12680×4260×4760 |

About us

GRAD Group devotes itself to be a central air conditioning customization expert around you and provides you a comprehensive energy solution, GRAD possesses national mechanical and electrical equipment installation Class I qualification and purification equipment installation Class II qualification. GRAD has the overall project contacting ability. It has contracted national class and provincial class technology research projects for many times. The accumulated patents for technolog achievements has passed 110 items. There are more than 300 senior engineers available for central air conditioning design and solution. The 700,000 ㎡ manufacturing base includes the whole central air conditioning series: from chiller to terminal products.

Main products:Central air conditioners,ventilators ,GRP Composite material products,Environment protection products

Employment : 2500+ employees

Registered capital: ¥ 100 million

Equipment price : ¥370 million

Total capital :¥ 925 million

Annual output value: ¥over 3 billion

Design team:300+

Overseas offices:

1. Thailand and Cambodia offices

2. USA branch company