Cooling Tower Solutions

1. Environmentally friendly and energy-saving

Closed-loop fluid circulation reduces scaling and clogging, saving energy by up to 95%

2. Professional customization

National-level cooling tower testing center and designated performance testing base, meeting customers' customized requirements

3. Efficient cooling

The secondary packing design and serpentine corrugated joint heat exchanger increase the heat exchange area by 15% per meter

4. Quality Assurance

The main components are matched with first-line brands at home and abroad

5. Easy installation

Modular design reduces on-site welding

Cooling Tower Solutions

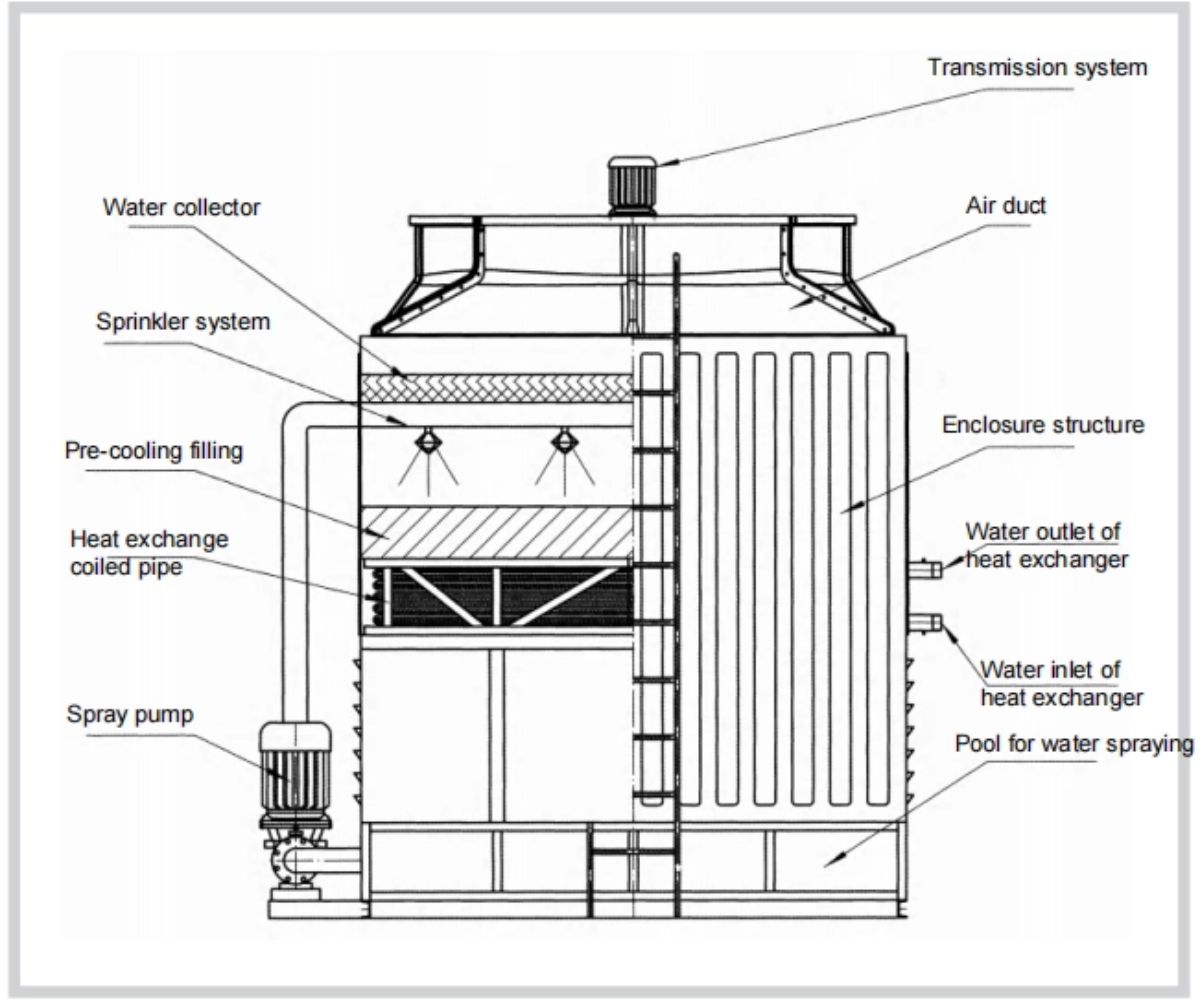

Cooling water tower principle and application:

Module of closed cooling tower is red copper coil with high heat transfer efficiency, allows working fluid (purified water or other liquid) pipeline pass through, makes heat exchange with air through fan to complete at a time so as to achieve energy efficiency and environmental protection and maintain pipeline cooled clean and smooth. It is available for long-term operation by connecting water inlet and outlet at user's site. It is another high-end choice for modern industrial cooling and is widely applicable to complete induction and heating equipment, IF furnace, die casting machine, etc.

★Induction heating industry

★Industrial fluid

★Air conditioning system

★Water jacket cooling of air compressor

★Injection molding machine cooling

★Transformer cooling

★Glass melting furnace cooling

★Power plant

★Chemical plant

The cold fluid flows through the coiled pipe in the closed cooling tower to conduct heat to the wall of coiled pipe; the fan at top of the tower conducts air-pumping operation. The outer-circulation spray water and refresh air taken in by the fan fully come into contact in the tower to exchange latent heat and sensible heat, and make the spray water temperature reduced. The spray water of lower temperature can form water film in coil pipe wall to absorb the heat of the coil pipe wall and thus take away the heat carrying of the medium to achieve the purpose of cooling. The pre-cooling filling in the tower helps to further cool the outer circulation. In the process of heat exchange, the heat carrying medium in the coiled pipe will maintain its original quality characteristics because it does not directly contact with the air and will not be polluted, concentrated, diluted and volatilized. In addition to a small amount of evaporation loss, the spray water outside the coiled pipe comes together at the bottom of the tower and circulates for use. In the process of heat exchange, the heat carrying medium in the coiled pipe will maintain its original quality characteristics because it does not directly contact with the air and will not be polluted, concentrated, diluted and volatilized. In addition to a small amount of evaporation loss, the spray water outside the coiled pipe comes together at the bottom of the tower and circulates for use

Model | Motor power KW | The fan diameter mm | Spray pump power KW | Spray flow m3/h | Pressure drop of the coil K Pa | Own weight Kg | Operating weight Kg | Overall dimensions A×B×H (mm) |

FBP-15 | 1.1 | 900 | 0.75 | 22 | 10 | 920 | 1830 | 1400×1400×2900 |

FBP-20 | 1.5 | 1200 | 0.75 | 34 | 15 | 1220 | 2560 | 1600×1600×3370 |

FBP-30 | 2.2 | 1400 | 1.1 | 45 | 25 | 1460 | 3066 | 2000×2000×3595 |

FBP-40 | 3 | 1500 | 1.5 | 60 | 30 | 1620 | 3402 | 2400×2400×3740 |

FBP-50 | 4 | 1768 | 1.5 | 60 | 45 | 1780 | 3740 | 2580×2580×3915 |

FBP-65 | 5.5 | 2360 | 3 | 118 | 60 | 2120 | 4450 | 3120×3120×4040 |

FBP-80 | 5.5 | 2560 | 3 | 118 | 75 | 2480 | 4960 | 3420×3420×4220 |

FBP-100 | 7.5 | 2954 | 4 | 180 | 15 | 2920 | 5840 | 3900×3900×4525 |

FBP-125 | 11 | 3340 | 5.5 | 217 | 20 | 3220 | 6440 | 4260×4260×4760 |

FBP-150 | 5.5×2 | 2560×2 | 3×2 | 118×2 | 75 | 4960 | 9920 | 6790×3420×4220 |

FBP-200 | 7.5×2 | 2954×2 | 4×2 | 180×2 | 15 | 5840 | 11680 | 7750×3900×4525 |

FBP-250 | 11×2 | 3340×2 | 5.5×2 | 217×2 | 20 | 6440 | 12880 | 8470×4260×4760 |

FBP-300 | 7.5×3 | 2954×3 | 4×3 | 180×3 | 15 | 8760 | 17520 | 11600×3900×4525 |

FBP-375 | 11×3 | 3340×3 | 5.5×3 | 217×3 | 20 | 9660 | 19320 | 12680×4260×4760 |

About us

Shandong GRAD Group is a large modern enterprise with over two decades history. Our business started in 1993, with staff of over 2200, we are focus on R&D, production, marketing, installation and maintenance for central air conditioning system and G R P composite material products. We are committed to providing customers with one-stop central air-conditioning and FRP composite material product solutions.

For central air conditioning products, we have production facility covering 450000 sqm, we can offer products for the whole system including chillers, heat pumps, cooling towers, A H U s, F C U s and ventilation products. To better participate international project, we have C T I, C E, A H R I certificates to guarantee our products quality.

For G R P composite material products, we have production facility covering 700000 sqm. With its feature of light weight, high strength, anti-corrosion and long service life, the G R P products are ideal replacement for steel products. We can offer process like vacuum injection, G R P winding, S M C mould pressing, molding pultrusion and hand paste. Based on different process, we can offer clients customized products.

GRAD sales network covers over 100 countries and regions like America, Australia Indonesia, Malaysia, UAE, Thailand, Nigeria etc and has established branch company in USA, and set up offices in Cambodia and Thailand to make overall layout of global market.

Our services

Before-sale services:

(1) Tell customers how to use our products and matters needing attention.

(2) Guide customers to choose the best and economic product, recover the investment within short time.

(3) Site inspection if you need.

In-Sale services:

(1)Quality control must be inspected strictly.

(2)In accordance with the agreements stipulated in the contract.

After-sale services:

(1) If the project needs our installation guidance, we can send our engineer and translator. We can also send customers installation video to

teach them how to fix and operate with our product.

(2) Usually, our product warranty is 18 months after leaving factory or 12 months after installation. within this months, all parts broken will be responsible for our factory.

(3) Regular contact with customer, consult with the customer feedback, come true with the customer's two-way communication.