Closed Circuit Cooling Tower

1. Environmentally friendly and energy-saving

Closed-loop fluid circulation reduces scaling and clogging, saving energy by up to 95%

2. Professional customization

National-level cooling tower testing center and designated performance testing base, meeting customers' customized requirements

3. Efficient cooling

The secondary packing design and serpentine corrugated joint heat exchanger increase the heat exchange area by 15% per meter

4. Quality Assurance

The main components are matched with first-line brands at home and abroad

5. Easy installation

Modular design reduces on-site welding

Closed Circuit Cooling Tower

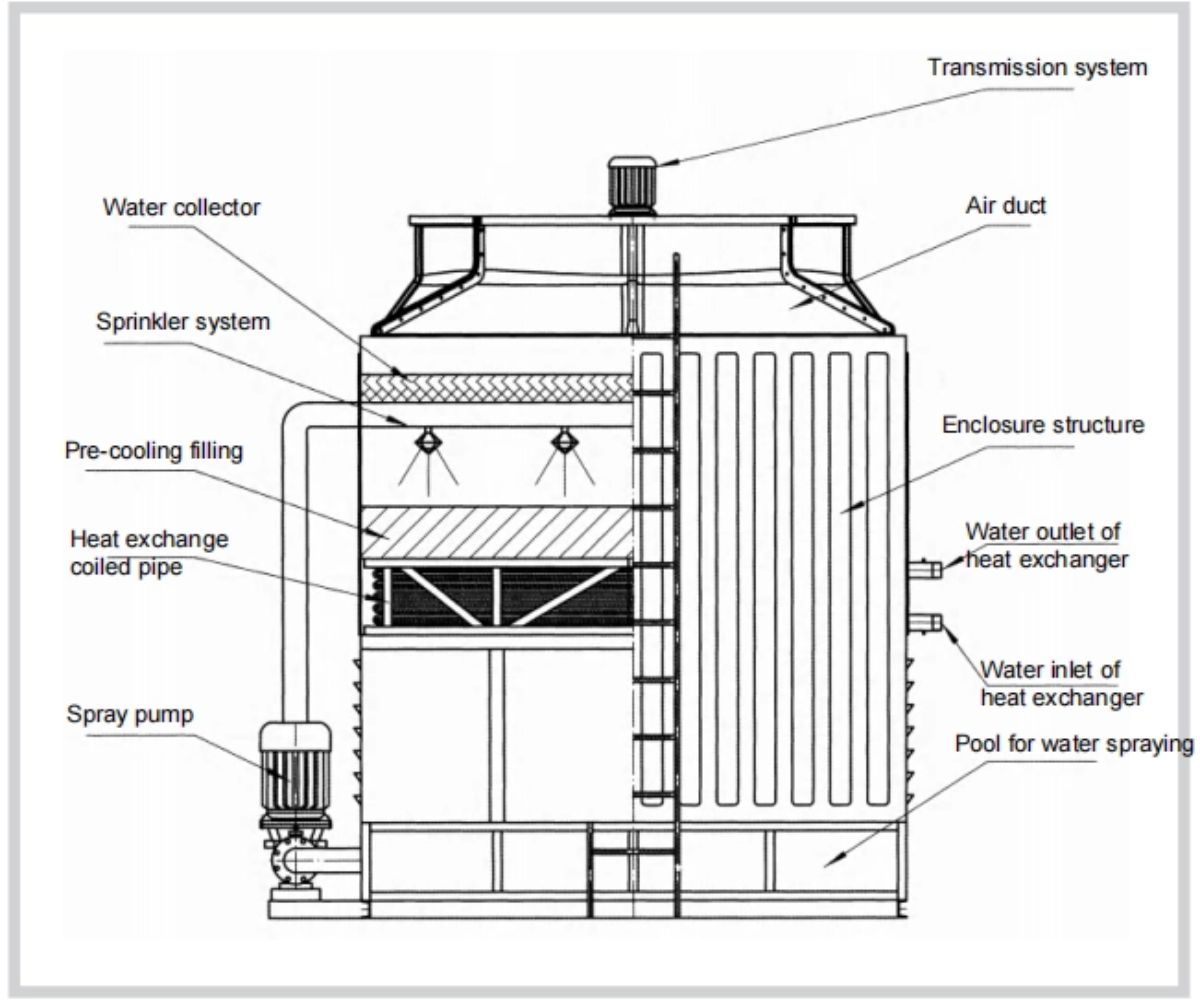

Working principle

The cold fluid flows through the coiled pipe in the closed cooling tower to conduct heat to the wall of coiled pipe; the fan at top of the tower conducts air-pumping operation. The outer-circulation spray water and refresh air taken in by the fan fully come into contact in the tower to exchange latent heat and sensible heat, and make the spray water temperature reduced. The spray water of lower temperature can form water film in coil pipe wall to absorb the heat of the coil pipe wall and thus take away the heat carrying of the medium to achieve the purpose of cooling. The pre-cooling filling in the tower helps to further cool the outer circulation. In the process of heat exchange, the heat carrying medium in the coiled pipe will maintain its original quality characteristics because it does not directly contact with the air and will not be polluted, concentrated, diluted and volatilized. In addition to a small amount of evaporation loss, the spray water outside the coiled pipe comes together at the bottom of the tower and circulates for use. In the process of heat exchange, the heat carrying medium in the coiled pipe will maintain its original quality characteristics because it does not directly contact with the air and will not be polluted, concentrated, diluted and volatilized. In addition to a small amount of evaporation loss, the spray water outside the coiled pipe comes together at the bottom of the tower and circulates for use.

The heat rejection structure of pre-cooling heat dissipation filling and heat exchange coiled pipe has the cooling efficiency and small volume. A shutter is set at the air inlet to avoid direct sunlight into the tower, prevent algae to grow and make the spray water clean. The heat transfer pipe uses T2 red copper pipe with the design pressure resistance of 1.6Mpa to keep the fluid from pollution. The heat exchange coiled pipe uses modular design. Adopt the aluminum alloy axial-flow fan, the wind speed at outlet is high to avoid back flow of the hot air, and the operation noise is low.

Schematic diagram of the cooling tower structure

Model | Motor power KW | The fan diameter mm | Spray pump power KW | Spray flow m3/h | Pressure drop of the coil K Pa | Own weight Kg | Operating weight Kg | Overall dimensions A×B×H (mm) |

FBP-15 | 1.1 | 900 | 0.75 | 22 | 10 | 920 | 1830 | 1400×1400×2900 |

FBP-20 | 1.5 | 1200 | 0.75 | 34 | 15 | 1220 | 2560 | 1600×1600×3370 |

FBP-30 | 2.2 | 1400 | 1.1 | 45 | 25 | 1460 | 3066 | 2000×2000×3595 |

FBP-40 | 3 | 1500 | 1.5 | 60 | 30 | 1620 | 3402 | 2400×2400×3740 |

FBP-50 | 4 | 1768 | 1.5 | 60 | 45 | 1780 | 3740 | 2580×2580×3915 |

FBP-65 | 5.5 | 2360 | 3 | 118 | 60 | 2120 | 4450 | 3120×3120×4040 |

FBP-80 | 5.5 | 2560 | 3 | 118 | 75 | 2480 | 4960 | 3420×3420×4220 |

FBP-100 | 7.5 | 2954 | 4 | 180 | 15 | 2920 | 5840 | 3900×3900×4525 |

FBP-125 | 11 | 3340 | 5.5 | 217 | 20 | 3220 | 6440 | 4260×4260×4760 |

FBP-150 | 5.5×2 | 2560×2 | 3×2 | 118×2 | 75 | 4960 | 9920 | 6790×3420×4220 |

FBP-200 | 7.5×2 | 2954×2 | 4×2 | 180×2 | 15 | 5840 | 11680 | 7750×3900×4525 |

FBP-250 | 11×2 | 3340×2 | 5.5×2 | 217×2 | 20 | 6440 | 12880 | 8470×4260×4760 |

FBP-300 | 7.5×3 | 2954×3 | 4×3 | 180×3 | 15 | 8760 | 17520 | 11600×3900×4525 |

FBP-375 | 11×3 | 3340×3 | 5.5×3 | 217×3 | 20 | 9660 | 19320 | 12680×4260×4760 |

About us

GRAD sales network covers over 100 countries and regions like America, Australia Indonesia, Malaysia, UAE, Thailand, Nigeria etc and has established branch company in USA, and set up offices in Cambodia and Thailand to make overall layout of global market.

Manufacturer:Shandong GRAD Group Co.,Ltd.

Established Time:1993

Covers an area of:700,000sqm

Main products:Central air conditioners,ventilators ,GRP Composite material products,Environment protection products

Employment : 2500+ employees

Registered capital: ¥ 100 million

Equipment price : ¥370 million

Total capital :¥ 925 million

Annual output value: ¥over 3 billion

Design team:300+

Overseas offices:

1. Thailand and Cambodia offices

2. USA branch company