Central Air Heat Pump

1.It operates efficiently within an ultra-wide ambient temperature range of -30℃ to 43℃

2. Precise frost measurement, rapid defrosting, reduced defrosting frequency, and shortened defrosting time

3. Mobile APP operation, remote control, fault warning, and online diagnosis

4. High-efficiency shell and tube heat exchange technology, water-side heat exchanger and flow protection, ultra-high energy efficiency ratio

5. It has a wide range of applications and is suitable for radiator heating, floor radiant heating, central air conditioning cooling and heating

Central Air Heat Pump

Product introduction:

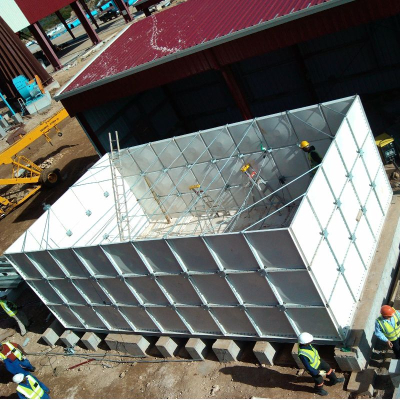

GRAD Air-cooled modular hot and cold water units do not require auxiliary equipment such as cooling water pumps and cooling towers, which can save a lot of space and installation costs. Modular design allows for free combination based on the size of the usage area. One main module can be connected in parallel with multiple sub-modules. The refrigeration systems are independent of each other and serve as backups for one another. Any abnormality in one of them does not affect the normal operation of the other equipment. This 68kw unit is suitable for villas ranging from 500 to 600 square meters. The ultra-low temperature module unit adopts the gas injection enthalpy technology, enabling a single compressor to achieve a two-stage compression effect, which is highly efficient and energy-saving. It can operate stably for heating in a low-temperature environment of -35℃, with the maximum outlet water temperature reaching over 70℃. The operating cost is reduced by more than 70% compared to traditional heating methods. It is low-carbon and environmentally friendly, making it the preferred model to replace coal-fired boilers for heating. The wall shows that the Zhangjiakou Olympic Village project of the Beijing Winter Olympics adopted our group's air-cooled modules, fully leveraging our advantage of starting up in low ambient temperatures. Next to it is the Xiongan New Area High-Speed Railway Station project. The group has taken on the entire central air conditioning machine room. Relying on a professional BIM team, it has created a prefabricated modular system to reduce on-site changes, ensure the construction period, and be efficient and environmentally friendly.

Features:

1.Easy to install and saving space:it needs no cooling pump or cooling tower which can save a lot installation and material cost. It can be set on roof, yard, balcony or other suitable open air positions but no need of machine room.

2.Multiple functions: one unit can offer both cooling and heat.

3.Modular design system: each refrigeration system is independent and can be standby of each other. One failure of the cooling system will not affect the other. And the light and small unit make the delivery much easier. The modular design can make it freely combined to meet various requirements.

Heat pump unit parameter table (low temperature type) | ||||||||

unit type | AR40BHR | AR50BHR | AR80BHR | AR100BHR | AR160BH | AR200BHR | ||

Normal Temperature | Heating Capacity | kW | 49 | 57 | 98 | 114 | 196 | 228 |

Input Power | kW | 11.1 | 12.9 | 22.2 | 25.8 | 44.4 | 51.6 | |

Water yield | L/h | 1054 | 1225 | 2108 | 2450 | 4216 | 4900 | |

Rated Working | Heating Capacity | kW | 37 | 44 | 74 | 88 | 148 | 176 |

Input Power | kW | 10.4 | 12.1 | 20.8 | 24.2 | 41.6 | 48.4 | |

Water yield | L/h | 795 | 946 | 1590 | 1892 | 3180 | 3784 | |

Low Temperature | Heating Capacity | kW | 28 | 30 | 52 | 60 | 104 | 120 |

Input Power | kW | 10.8 | 12.6 | 21.6 | 25.2 | 43.2 | 50.4 | |

Water yield | L/h | 486 | 560 | 972 | 1120 | 1944 | 2240 | |

Climatic type (Outdoor ambient temperature range) | ‘-30℃~48℃ | |||||||

Maximum outlet temperature | 60℃ | |||||||

Power supply specification | 3N~50Hz 380V | |||||||

Maximum operating current of the unit | A | 30 | 40 | 60 | 80 | 120 | 160 | |

Refrigerant | R410A | |||||||

Waterside | Circulating water flow | m3/h | 8.4 | 9.8 | 16.9 | 19.6 | 33.7 | 39.2 |

resistance | kPa | 15~40 | ||||||

Inlet and outlet nozzle size | DN | 40 | 40 | 65 | 65 | 80 | 80 | |

Overall | Length | mm | 1200 | 1200 | 2110 | 2110 | 2110 | 2110 |

Width | mm | 1080 | 1080 | 1080 | 1080 | 2405 | 2405 | |

Height | mm | 2160 | 2160 | 2160 | 2160 | 2160 | 2160 | |

Noise | dB(A) | 66 | 67 | 68 | 69 | 70 | 70 | |

Unit weight | kg | 400 | 450 | 800 | 850 | 1600 | 1650 | |

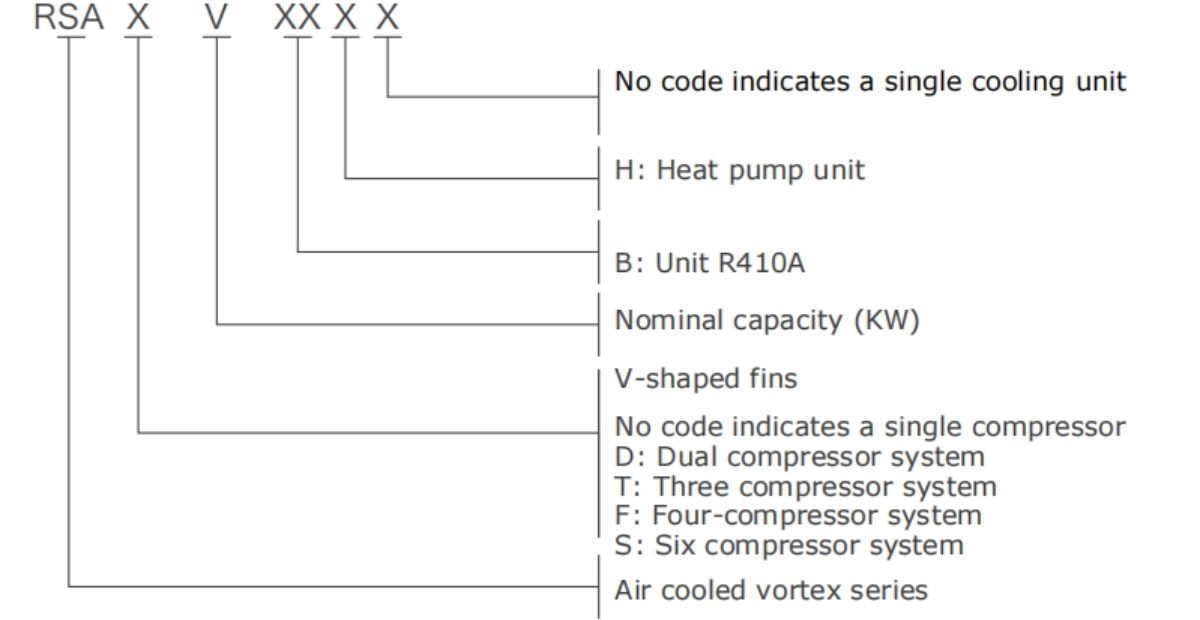

Air-cooled modular cold (hot) water unit

● The use of electronic expansion valve intelligent adjustment of refrigerant flow, more accurate control, more reliable unit operation.

● The use of environmental protection R410A refrigerant, wide operating range, refrigeration operating environment temperature of 18 ~ 48℃, heating operating environment temperature range of -15 ~ 25℃, applicable to a wider range of areas.

About us

Shandong GRAD Group is a large modern enterprise with over two decades history. Our business started in 1993, with staff of over 2200, we are focus on R&D, production, marketing, installation and maintenance for central air conditioning system and G R P composite material products. We are committed to providing customers with one-stop central air-conditioning and FRP composite material product solutions.

For central air conditioning products, we have production facility covering 450000 sqm, we can offer products for the whole system including chillers, heat pumps, cooling towers, A H U s, F C U s and ventilation products. To better participate international project, we have C T I, C E, A H R I certificates to guarantee our products quality.

For G R P composite material products, we have production facility covering 700000 sqm. With its feature of light weight, high strength, anti-corrosion and long service life, the G R P products are ideal replacement for steel products. We can offer process like vacuum injection, G R P winding, S M C mould pressing, molding pultrusion and hand paste. Based on different process, we can offer clients customized products.

GRAD international business starts in 2009, now its products have been exported to 100 countries and regions.