Geothermal Heating And Cooling

1. Bipolar compression

Adopting bipolar compression enhances the energy efficiency of the unit and broadens the capacity adjustment range of the unit

2. National patent

High-efficiency falling film evaporation technology

3. Invention patent

Flash evaporation tank technology

4. Self-developed

Remote intelligent control

5. Anti-surge technology

The combination of prevention, control and alarm makes the unit safer and more reliable

Geothermal Heating And Cooling

Ground source heat pump units mainly use groundwater or soil below 100 meters as the exchange medium to achieve energy-saving operation of the main unit, and their energy-saving rate can reach 30% to 40%. All these units are equipped with original imported compressors from internationally renowned brands (such as Taiwan Hanbell, Germany Bitzer, the United States Wheelbase, Japan Sanyo, etc.), and the main unit components are mainly from international first-line brands. The condenser and evaporator are independently designed and produced by the company, which can be optimally matched with the compressor to achieve the highest energy efficiency ratio. This unit is equipped with our independently developed falling film evaporator, making the unit more energy-efficient and efficient. Next to it is the display of the Internet of Things control system we have matched, which realizes the intelligent control of the central air conditioning system and achieves energy-saving effects.

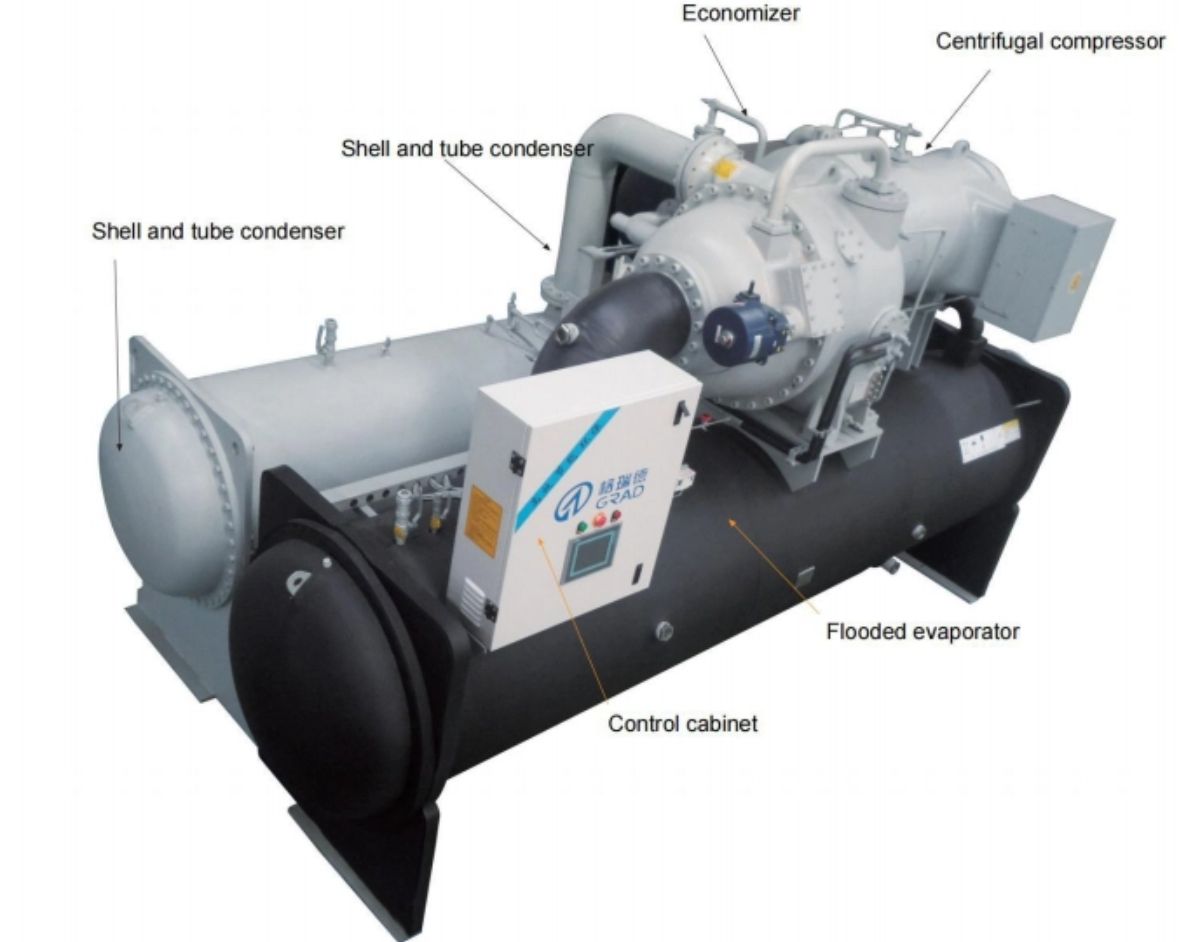

Centrifugal chiller is the use of electricity as a power source, freon refrigerant in the evaporator refrigerant evaporation, freon evaporation wet steam compressor compressed into high temperature and high pressure gas, the water cooling condenser is condensed into a liquid, the expansion valve throttling recirculation into the evaporator. Thus, the freezing water at 7 ℃ -12 ℃ is made for air conditioning at the end of air conditioning.

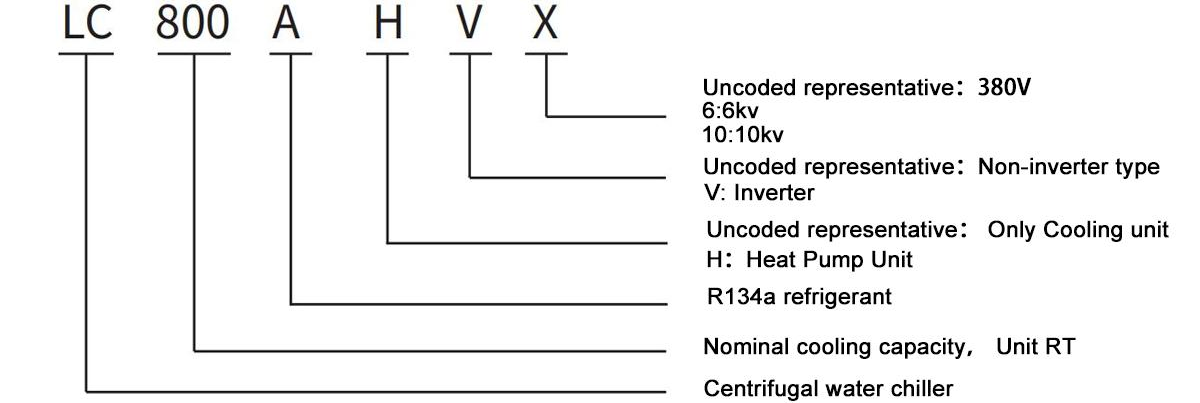

Model Description

Technical parameters table of centrifugal water cooled cold water chiller

Model | LC350A | LC400A | LC450A | LC500A | LC550A | LC600A | LC650A | LC700A | LC750A | LC800A | LC850A | LC900A | ||

Cooling capacity | RT | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | |

KW | 1231 | 1407 | 1583 | 1759 | 1934 | 2286 | 2462 | 2638 | 2814 | 3165 | 3341 | 3165 | ||

104Kca/h | 106 | 121 | 136 | 151 | 166 | 197 | 212 | 227 | 242 | 257 | 272 | 272 | ||

Electric motor | Power (kw) | 208 | 242 | 277 | 306 | 334 | 340 | 369 | 400 | 425 | 452 | 483 | 513 | |

Power supply | 380-3ph-50hz | 6000/10000V-3ph-50hz | ||||||||||||

Cooling mode | Refrigerant spray cooling | |||||||||||||

Performance factor COP (KW/KW) | 5.92 | 5.81 | 5.72 | 5.75 | 5.8 | 6.2 | 6.19 | 6.16 | 6.21 | 6.22 | 6.19 | 6.17 | ||

refrigerant | R134a | |||||||||||||

Evaporator | Cold water flow (m3/h) | 212 | 242 | 272 | 302 | 333 | 363 | 393 | 423 | 454 | 484 | 514 | 544 | |

Cold water press drop ( kpa) | 65 | 84 | 82 | 86 | 87 | 84 | 81 | 81 | 87 | 88 | 87 | 87 | ||

Number of pass cold water inlet and outlet | 2 | |||||||||||||

Temperature ( ℃) | 12/7 | |||||||||||||

Connection diameter (DN) | 200 | 250 | 300 | |||||||||||

Condenser | Cooling water flow (m3/h) | 265 | 302 | 340 | 378 | 416 | 454 | 491 | 529 | 567 | 605 | 643 | 681 | |

Cooling water press drop ( kpa) | 70 | 85 | 87 | 84 | 89 | 87 | 80 | 77 | 84 | 88 | 85 | 84 | ||

Number of pass cooling water inlet and outlet | 2 | |||||||||||||

Temperature ( ℃) | 30/35 | |||||||||||||

Connection diameter (DN) | 200 | 250 | 300 | |||||||||||

Unit features

(1)Unit adopts two-stage centrifugal compressor with high energy efficiency

•Three-phase bipolar squirrel cage induction motor Y- △ start, direct start or soft start.

•High efficiency two-stage compression and economizer design. Protection level - IP54.

•High-strength aluminum enclosed impeller. Enclosed impeller is more efficient than open type.

(2)The unit supply voltage is optional: 380V/6000V/10000V

•Select high voltage to reduce initial investment; require no transformer; save cable cost; save electrical equipment installation cost and machine room investment.

(3)The unit adopts SIEMENS microcomputer intelligent control

•Simple operation, complete protection, Chinese interface, real-time monitoring, clear display of all running data, extremely convenient operation. Capacity adjustment is wide with 10~100% stepless capacity adjustment.

•It has perfect protection functions, such as power protection, high voltage protection, low voltage protection, oil temperature protection, etc., which makes the unit running more reliable.

•The unit has advanced multiple anti-surge function, and adopts the combination of prevention, control and alarm, so that the unit can meet customers’ demand for cooling capacity in a safe range.

•Visually display switch state, analog state, input, alarm and fault, etc.

FAQ

Q1. Where is your loading port?

A: Qingdao/Shanghai/Tianjin, China or else port as for your request.

Q2. What's your company's main products?

A: Our company is specialized in central air-conditioning,ventilation and GRP Composite material products.

Q3. What’s your payment term.

A:T/T,30% deposit,70% before delivery or 100% Irrevocable L/C at sight.

Q4. What’s your Warranty.

A:Warranty for 12 months from the date of shipment from the factory.

Company Information

Manufacturer:Shandong GRAD Group Co.,Ltd.

Established Time:1993

Covers an area of:700,000sqm

Main products:Central air conditioners,ventilators ,GRP Composite material products,Environment protection products

Employment : 2500+ employees

Registered capital: ¥ 100 million

Equipment price : ¥370 million

Total capital :¥ 925 million

Annual output value: ¥over 3 billion

Design team:300+

Overseas offices:

1. Thailand and Cambodia offices

2. USA branch company