Sistem Chiller Water Cooled

1.The heat exchange efficiency is increased by 10%, the refrigerant charge is reduced by 27%, and the volume of the unit can be effectively reduced by more than 20%

2. Remote intelligent services

3. Applicable to multiple scenarios and working conditions

4. Low operation and maintenance costs

5. The falling film evaporation technology has been granted a national patent

Sistem Chiller Water Cooled

Introduction of Water Cooled Screw Chiller

The water-cooled screw chiller adopts the semi-closed double-screw compressor,and uses the single circuit or multi-circuit design.The protection and control facilities are placed in the control cabinetand the running state of the host is displayed on the computermonitor.All units are assembled in the factory and leave the factoryafter being operated and debugged.The application scope of thisseries of the units includes various commercial and civilian buildingfacilities,such as shopping malls,office buildings,commercialbuildings,factory workshops,hotels,hospitals and so on.

The design,manufacturing and inspection of GRAD water cooledscrew chiller shall be in accordance with the GB/T18430.1-2007Water Chilling(Heat Pump)Packages Use the Vapor compressionCycle-Part 1:Water Chilling(Heat Pump)Packages for Industrial&Commercial and Similar Application.

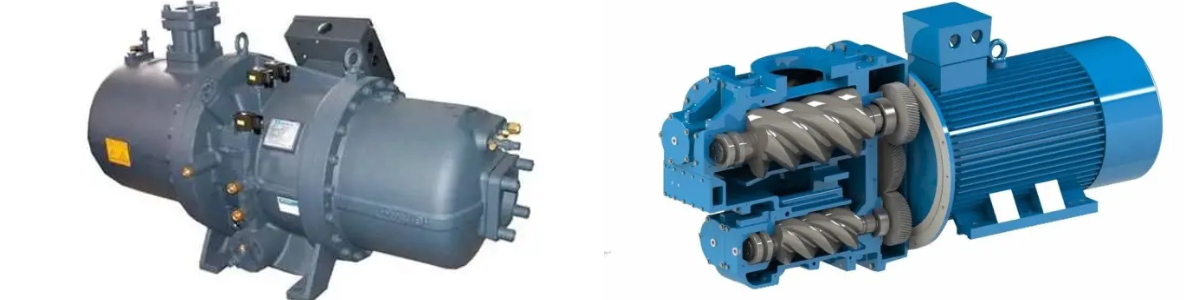

1.High efficiency compressor

The unit adopts wellknown brand semi-closed screw compressor.Compared with piston compressor,semi-closed screwcompressor has the following advantages:

(1)Fewer parts(about 1/3 of the piston compressor),simple structure,less wearing parts,high reliability,long life

(2)The compressor:uniform and continuous suction and exhaust,low exhaust temperature,small vibration,insensitive to wetcompression,and strong resistance to liquid shock;

(3)COP of dry unit can reach more than 4.6,COP of full liquid/falling film unit can reach more than 5.3

(4)In terms of energy regulation,screw compressors have more advantages,achieving 25-100%stepless energy regulation.

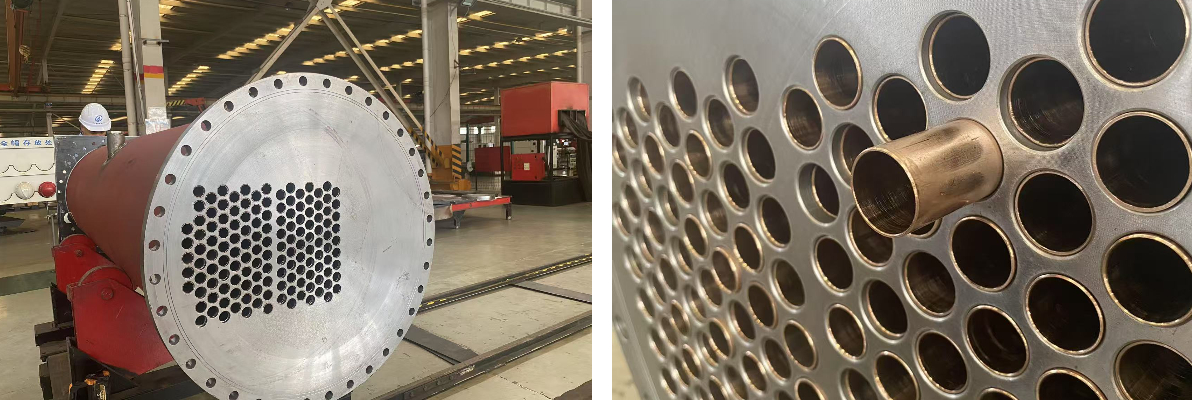

2.Shell and tube evaporator

1.The dry unit matches the dry shell and tube evaporator with high efficiency heat exchange tube

(1)The most advanced DAE eficient evaporation heat transfer tube,multi-head spiral fin and spiral protruding on the surface of the tube cangreatly improve the heat transfer coefficient and heat transfer capacity.

(2)The internal structure of the evaporator is optimized and the efficent liquid homogenizer is configured to solve the problem of theuniformity of the distribution of cooling in the system.

(3)Improve the sealing structure of the refrigerant water baffle,solve the problems of the baffle leakage,greatly improve the heat transferefficiency of the evaporator,so as to ensure that the unit reaches a higher performance level.

(4)The unique heat exchanger cooling process design technology is used to rationally match the system to ensure the balanced relationshipbetween the refrigeration process and the water side cooling capacity,and give full play to the high efficiency of the heatexchanger:meanwhile Reasonable system matching makes the unit more energy saving.

3.Ultra-efficient falling film evaporator

(1)Single circuit or double circuit refrigerant system design:the refrigerant evaporates in the shell side,and the coldwater flows through the pipe to be cooled.All heat exchange tubes are infiltrated in the refrigerant,Effectively increase the heat transfer efficiency,improve the evaporation temperature.

(2)Shell:The production and test are in accordance with the provisions of NB/T47012-2020 "Pressure vessel forrefrigeration equipment"standard.

(3)Copper pipe:seamless copper pipe for full liquid unit using the most advanced internal and external finstrengthening technology in China.

(4)Effectively control the liquid level with the electronic expansion valve.Make the unit to achieve the best operatingstate.

(5)Compared with the full liquid evaporator,the falling film evaporator reduces the amount of refrigerant charge,improves the of about 10%,of the heat exchange efficiency,and makes the oil return more stable and the operationmore reliable.

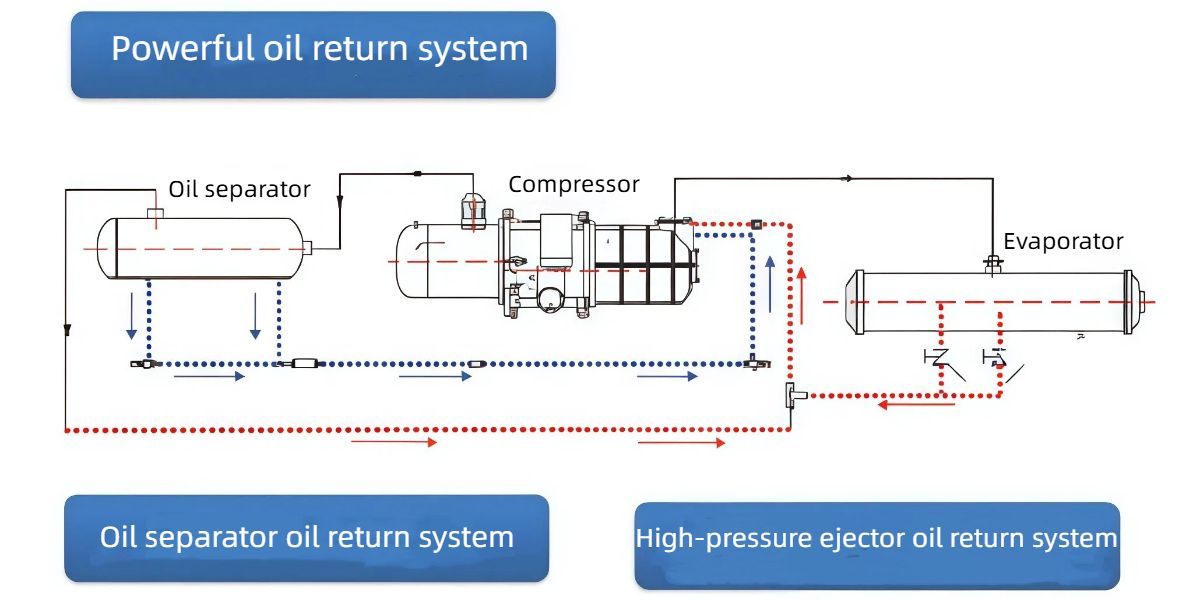

4.Core technology

Through four core technologies - real-time flow control, efficient falling film evaporation, efficient oil separation and return technology, and Internet of Things remote intelligent services - the unit's energy efficiency has been increased by 10%, and its operation and maintenance are worry-free and cost-effective. The unit is more efficient, reliable and stable. The remote intelligent service center can monitor in real time and handle faults quickly online, providing customers with a more considerate and prompt product experience and after-sales service.

The GRAD national patent external high-efficiency oil separation technology, through the high-efficiency external secondary oil separator composed of the shell, end head, intake pipe assembly, baffle, oil and gas filter screen assembly, outlet assembly, return oil port and sight glass, adopts the three-stage separation principle of oil and gas collision deflection separation, gravity sedimentation separation and filtration separation to separate the refrigerant gas and the lubricating oil in the gas Its structure is simple, easy to manufacture, with high separation efficiency, stable and reliable operation of the unit, and no risk of liquid carrying in the suction.

6.Test ability, technical level

1.GRAD has the National Laboratory of Air Conditioning Products recognized by CNAS, which is used for the design, development and experimental research of water-cooled chiller and the factory test of products.

2.Strict factory product quality control, so that users can buy at ease, with satisfaction.

3.GRAD screw type water cooled chiller series products ware tested by the national air conditioning quality testing center, the technical performance indicators are higher than GB/T184330.1-2007"Vapor compression cycle cold water (heat pump) unit Part 1: Industrial or commercial and similar uses of cold water (heat pump) units "standard, product quality is stable, reliable operation, has been praised by the majority of users at home and abroad.

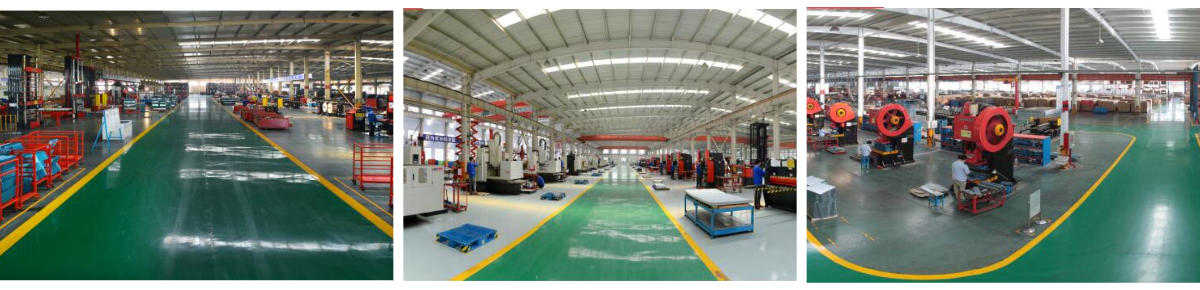

Establised in 1993, GRAD Group covers an area of 1.15 million square meters and has more than 2,000 employees, with an annual output value of nearly 4 billion yuan. GRAD Group's main business: central air conditioning chiller and terminal products, FRP water tank, FRP winding pipe, FRP storage tank, wind turbine cabin cover, environmental protection equipment, and other more than 130 varieties. GRAD Group is the pillar enterprise of the “Dezhou Central Air-Conditioning City” named by the China Refrigeration and Air-Conditioning Industry Association. It ranks the top 10 among central air-conditioning enterprises in the country, and gets the first-class qualification for the installation of national electromechanical equipment and the second-class qualification for air purification engineering. GRAD Group can undertake central air conditioning engineering, purification engineering construction.