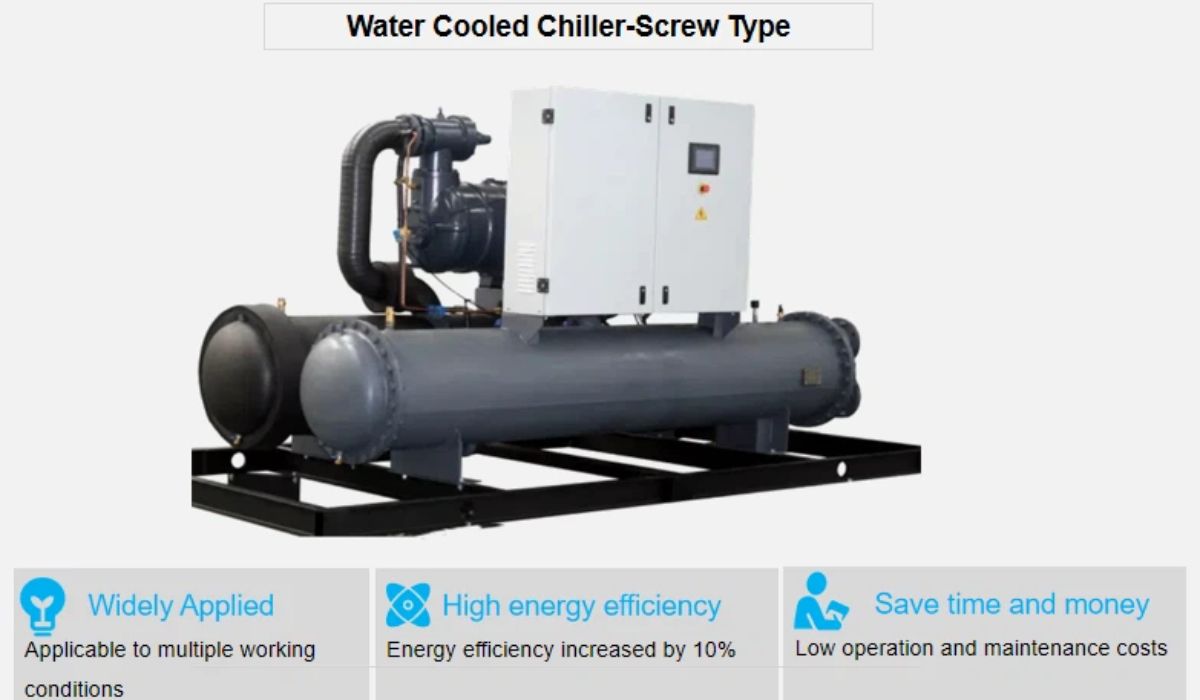

Water Cooled Screw Chiller

1.The heat exchange efficiency is increased by 10%, the refrigerant charge is reduced by 27%, and the volume of the unit can be effectively reduced by more than 20%

2. Remote intelligent services

3. Applicable to multiple scenarios and working conditions

4. Low operation and maintenance costs

5. The falling film evaporation technology has been granted a national patent

The GRAD water-cooled screw chiller employs semi-hermetic twin-screw compressors with either single or multi-circuit configurations. Its integrated control cabinet houses all protective and monitoring systems, while operational status is displayed on a computer interface. Each unit undergoes complete factory assembly, testing, and commissioning prior to shipment.

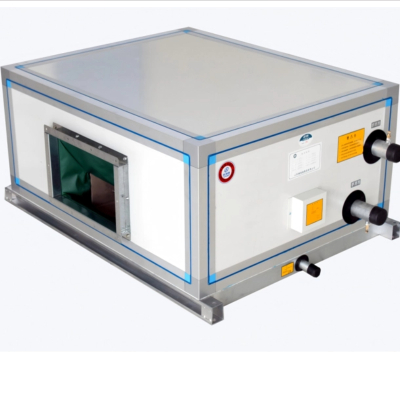

This product series finds wide application across diverse commercial and civil structures including retail complexes, office towers, commercial buildings, industrial plants, hospitality venues, and medical facilities.

GRAD's water-cooled screw chillers strictly comply with GB/T18430.1-2007 standards for design, production, and quality control. This national standard regulates vapor compression cycle water chilling (heat pump) packages for industrial, commercial, and similar applications.

Core Technological Advantages

GRAD’s water-cooled screw chillers incorporate four key innovations—real-time flow control, high-efficiency falling film evaporation, advanced oil separation and return technology, and IoT-enabled remote intelligent services—enhancing energy efficiency by 10% while ensuring low-maintenance, cost-effective operation. The system delivers superior efficiency, reliability, and stability, with remote monitoring enabling real-time fault diagnosis and swift online resolution, providing customers with seamless product performance and responsive after-sales support.

Energy-Saving Performance

Featuring nationally patented falling film evaporation technology, the chiller utilizes high-efficiency falling film heat exchange tubes. The refrigerant is evenly distributed via a liquid distributor, forming a thin film over the tube array to maximize heat transfer. Compared to conventional flooded evaporators, this technology:

Increases heat exchange efficiency by over 10%

Reduces refrigerant charge by 27%

Enhances oil return performance

Decreases unit size by more than 20%, optimizing machine room space

Patent Details: Falling Film Evaporator for Refrigeration and Air Conditioning (Patent No. ZL201520313780.5)

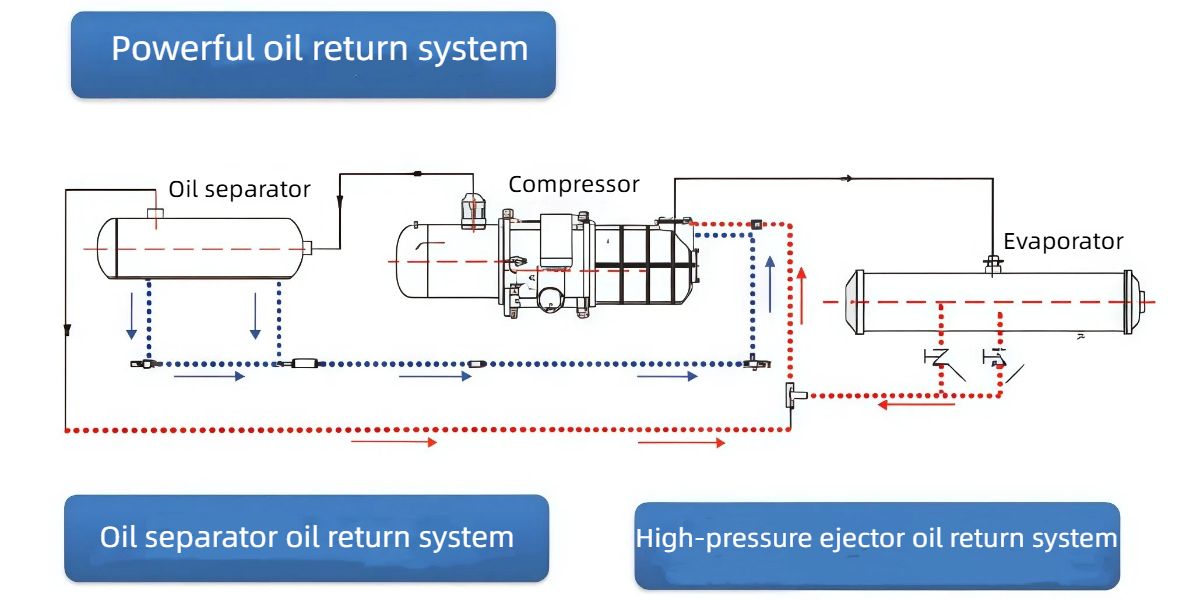

GRAD’s externally mounted high-efficiency oil separation system (a national patent) employs a three-stage separation process:

Deflection separation (oil-gas collision)

Gravity sedimentation separation

Filtration separation

This design ensures effective separation of refrigerant gas and lubricating oil, offering:

Simple, durable construction

High separation efficiency

Stable, reliable operation

Elimination of liquid carryover risk

By integrating these advanced technologies, GRAD chillers deliver unmatched performance, energy savings, and operational dependability.

1.GRAD has the National Laboratory of Air Conditioning Products recognized by CNAS, which is used for the design, development and experimental research of water-cooled chiller and the factory test of products.

2.Strict factory product quality control, so that users can buy at ease, with satisfaction.

3.GRAD screw type water cooled chiller series products ware tested by the national air conditioning quality testing center, the technical performance indicators are higher than GB/T184330.1-2007"Vapor compression cycle cold water (heat pump) unit Part 1: Industrial or commercial and similar uses of cold water (heat pump) units "standard, product quality is stable, reliable operation, has been praised by the majority of users at home and abroad.

About us

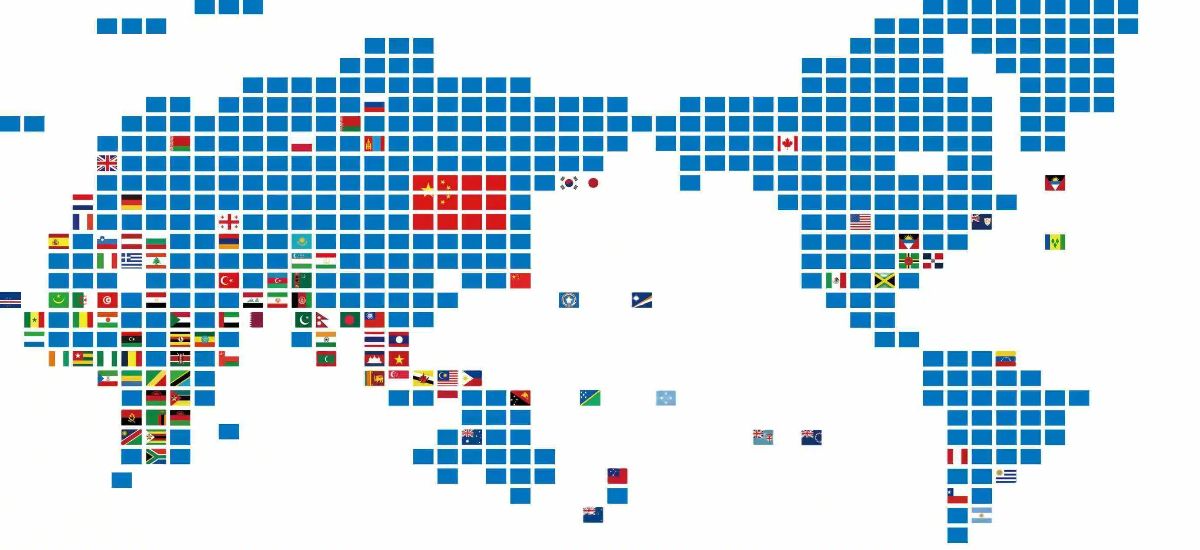

Shandong GRAD Group Co., Ltd. is a leading global manufacturer specializing in HVAC (Heating, Ventilation, and Air Conditioning) solutions. With over 30 years of production experienceand 16+ years in international business, we have built a strong reputation for innovation, reliability, and excellence. Our products are exported to 100+ countries, demonstrating our commitment to quality and customer satisfaction worldwide. Operating from a 500,000 sqm state-of-the-art production facility, we employ 2,000+ skilled professionals dedicated to delivering cutting-edge HVAC technologies. GRAD Group holds 1,000+ patents, underscoring our leadership in R&D and technological advancement. Whether for commercial, or industrial applications, we provide energy-efficient, sustainable, and high-performance HVAC solutions tailored to global market needs.

GRAD sales network covers over 100 countries and regions like America, Australia Indonesia, Malaysia, UAE, Thailand, Nigeria etc and has established branch company in USA, and set up offices in Cambodia and Thailand to make overall layout of global market.