Water Cooling Tower

1.CTI certification

Authoritative certification, exported to the European and American markets

2. Long lifespan

The vacuum intake air duct and pultruded panel are made of fiberglass reinforced plastic, which is of high strength and corrosion resistance

3. Low noise

Patented technology of integral water spray packing, with lower noise

4. Efficient cooling

Integral packing, uniform water distribution and large heat exchange area

5. Easy installation

Modular design: Steel parts are welded into blocks before leaving the factory, reducing on-site welding

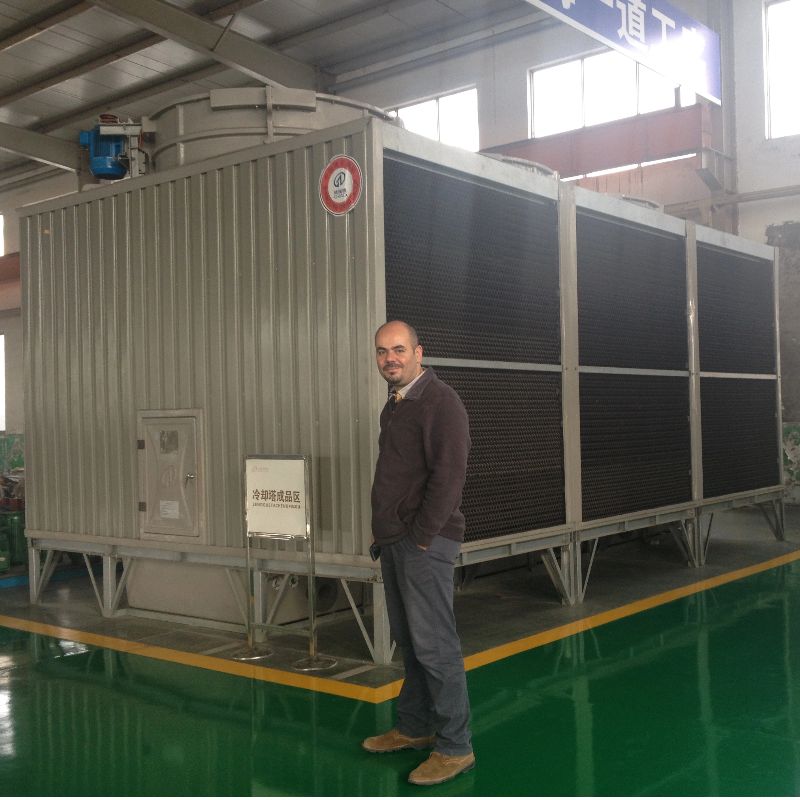

Water Cooling Tower

Special Design, Special Quality

BHD series of square cross-flow GRP cooling towers are optimized in design of their structure and process on the basis of the traditional square GRP cooling tower. The function of each inner part is reasonably selected. All components and materials are strictly selected and tested to ensure a long service life and reliable operation. The unique excellent mechanized process improvement provides reliable guarantee for high quality of the cooling tower and effectively reduces the weight of the tower to make the BHD series of square counter-flow GRP cooling towers with the characteristics of small volume, light weight, high efficiency, durability and stable operation. At the same time, the cooling towers can be equipped with a new frequency conversion device to realize automatic regulation of fan speed with cooling water temperature under different temperature conditions and different load conditions, so as to achieve the purpose of energy saving and noise reduction, and save equipment operation cost for users.

Technical parameters of BHD series of square cross-flow GRP cooling towers

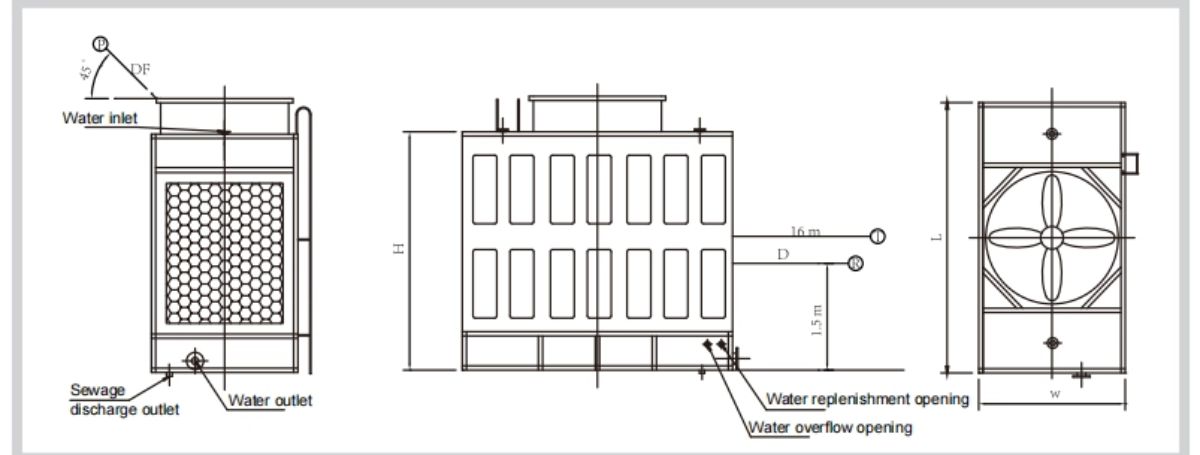

1. The measuring points (R) and (T) are all in the direction of air inlet of the cooling tower. The equivalent diameter D=1.13 W L, among which, L and W are respectively the side length of the cooling tower.

2. It must be quiet around the cooling tower before determination of noise, the environmental noise should be 10dB (A) or more lower than the noise at the measuring point R under normal work of the tower, otherwise, it should be corrected. Please consult the technical personnel of the company for corrected value.

3. DF shown in the figure is the distance of equivalent diameter of the air outlet: 1.5≤DF≤5m.

Technical and specification parameters of BHD-100~BHD- 700

Model | Water yield m3/h | Cooling efficient×103 K cal/h | Motor power KW | The fan diameter Φ mm | The tower body lift mH2O | Overall dimensions (mm) | Noise dB(A) | ||||

L | W | H | P | R | T | ||||||

BHD-100 | 100 | 500 | 2.2 | 1768 | 3.5 | 3800 | 2060 | 3350 | 60.1 | 57.4 | 50.0 |

BHD-125 | 125 | 625 | 3 | 1768 | 3.5 | 4200 | 2060 | 3350 | 61.2 | 57.6 | 51.2 |

BHD-150 | 150 | 750 | 3 | 2168 | 3.6 | 4200 | 2460 | 3350 | 61.4 | 57.8 | 51.5 |

BHD-175 | 175 | 875 | 4 | 2168 | 3.6 | 4600 | 2460 | 3350 | 62.3 | 58.1 | 52.9 |

BHD-200 | 200 | 1000 | 4 | 2560 | 3.8 | 4600 | 2860 | 3350 | 62.5 | 58.7 | 53.4 |

BHD-225 | 225 | 1125 | 5.5 | 2560 | 3.9 | 5000 | 2860 | 4000 | 63.1 | 59.3 | 53.8 |

BHD-250 | 250 | 1250 | 5.5 | 2954 | 4.0 | 5000 | 3260 | 4000 | 63.4 | 59.8 | 54.5 |

BHD-300 | 300 | 1500 | 7.5 | 2954 | 4.0 | 5400 | 3260 | 4000 | 64.3 | 60.6 | 55.2 |

BHD-330 | 330 | 1650 | 7.5 | 3340 | 4.2 | 5400 | 3660 | 4000 | 63.9 | 60.4 | 54.7 |

BHD-370 | 370 | 1850 | 11 | 3340 | 4.4 | 5800 | 3660 | 4500 | 64.2 | 60.7 | 55.1 |

BHD-400 | 400 | 2000 | 11 | 3744 | 4.9 | 5800 | 4060 | 4500 | 64.7 | 61.3 | 55.7 |

BHD-450 | 450 | 2250 | 15 | 3744 | 4.9 | 6200 | 4060 | 4500 | 65.3 | 61.4 | 56.1 |

BHD-500 | 500 | 2500 | 15 | 4140 | 5.0 | 6600 | 4460 | 5000 | 65.4 | 61.7 | 56.3 |

BHD-600 | 600 | 3000 | 18.5 | 4140 | 5.3 | 7000 | 4460 | 5000 | 66.1 | 62.4 | 57.1 |

BHD-700 | 700 | 3500 | 18.5 | 4540 | 5.3 | 7400 | 4860 | 5000 | 67.3 | 63.6 | 58.2 |

Note:

1. Test the cooling efficiency under the working conditions of the water inlet temperature of 37°C, water outlet temperature of 32°C, ambient wet bulb temperature of 28°C and atmospheric pressure of 99.4kPa.

2.The indicated noise value is the measured value at a running frequency of 50Hz. Please see the frequency comparison table for actual running noise. (The data is subject to change without prior notice)

About us

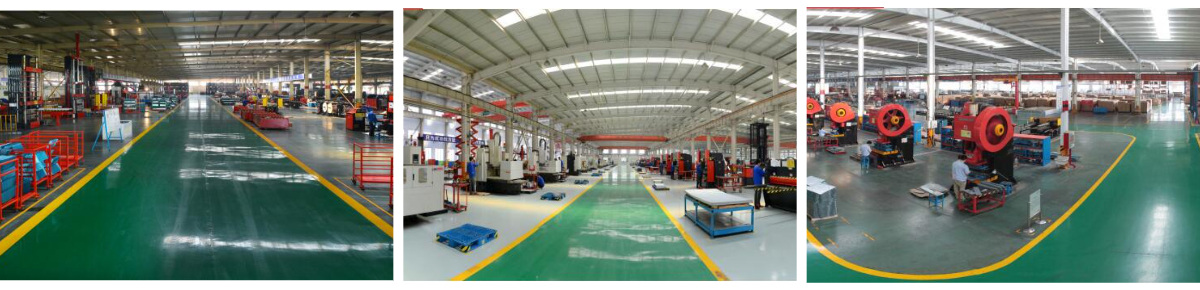

Shandong GRAD Group is a large modern enterprise with over two decades history. Our business started in 1993, with staff of over 2200, we are focus on R&D, production, marketing, installation and maintenance for central air conditioning system and G R P composite material products. We are committed to providing customers with one-stop central air-conditioning and FRP composite material product solutions.

For central air conditioning products, we have production facility covering 450000 sqm, we can offer products for the whole system including chillers, heat pumps, cooling towers, A H U s, F C U s and ventilation products. To better participate international project, we have C T I, C E, A H R I certificates to guarantee our products quality.

For G R P composite material products, we have production facility covering 700000 sqm. With its feature of light weight, high strength, anti-corrosion and long service life, the G R P products are ideal replacement for steel products. We can offer process like vacuum injection, G R P winding, S M C mould pressing, molding pultrusion and hand paste. Based on different process, we can offer clients customized products.

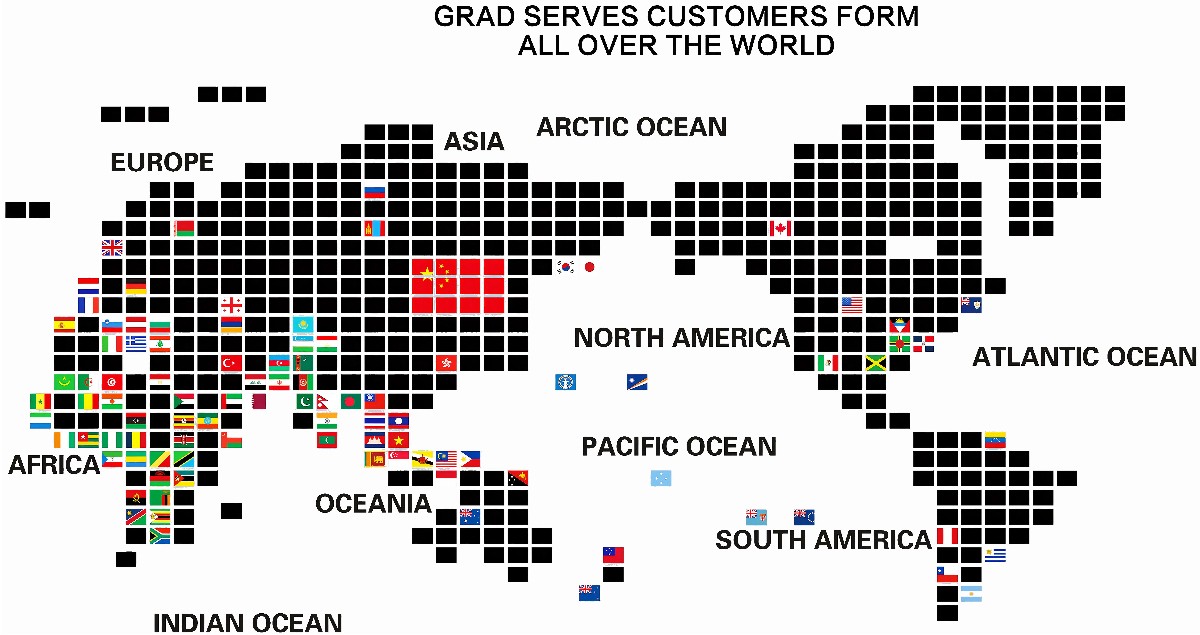

GRAD international business starts in 2009, now its products have been exported to 100 countries and regions.