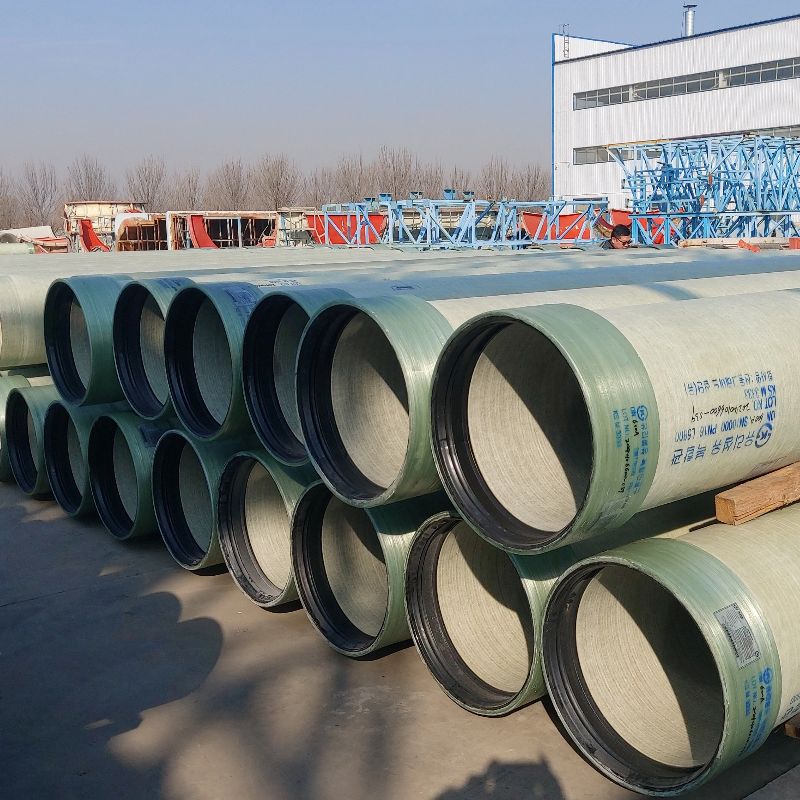

FRP Fiberglass Reinforced Plastic Pipe

Why choose GRAD FRP winding pipe?

1.Top 3 brands and annual output manufacturers.

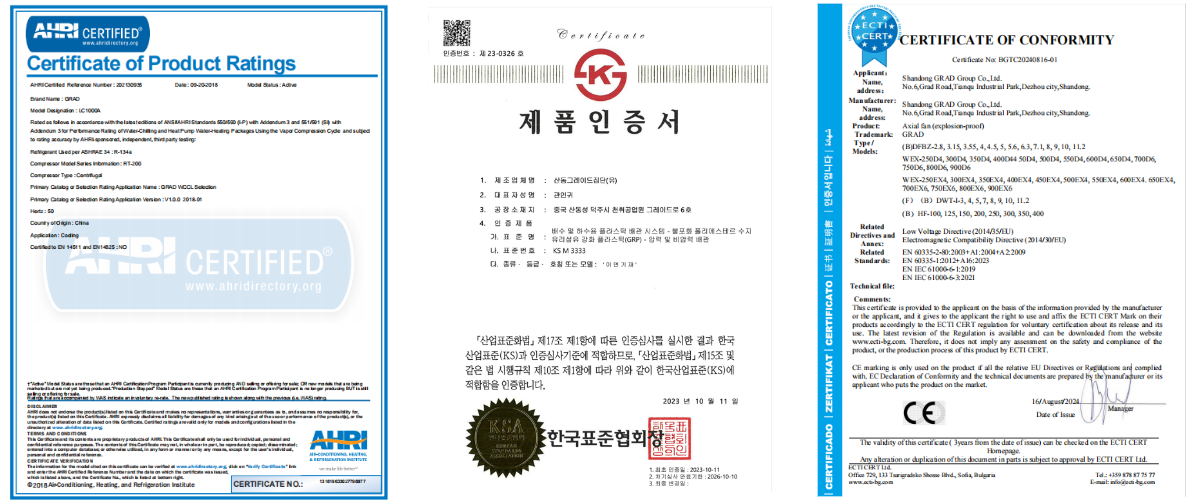

2.Qualified by Korean KS certificate, which is the only one in China.

3.Over 30+ years production experience since 1993.

4.50+ years of lifespan, durable products.

5.China national projects participation experience:

South-to-North Water Diversion Project

Yellow Water to East China Diversion Project

Guizhou Jiayan Water Conservancy Project and Northwest Guizhou Water Supply Project

6.Overseas pipeline project achievements:

Yeosu Water Treatment Plant Project in South Korea

Sewage Pipeline Project in Battambang Province, Cambodia

Indonesia West Kalimantan 2 x 50 MW coal-fired power stations FRP pipe project

FRP Fiberglass Reinforced Plastic Pipe

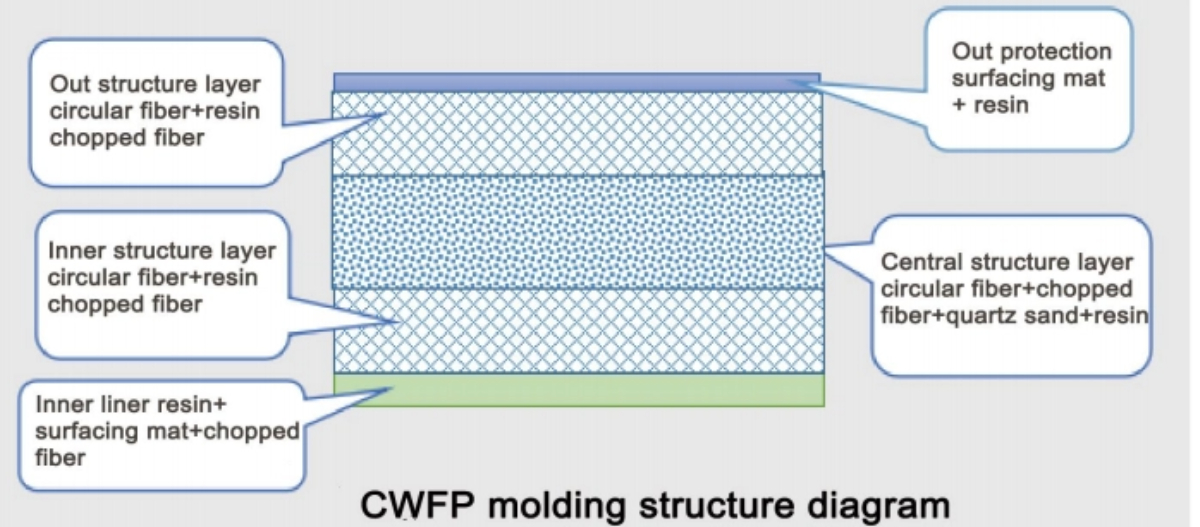

FRP Fiberglass Reinforced Plastic Pipe are manufactured using the process of Continuance Filament Winding (CFW). Our range of GRP pipe products offer structural strengths and corrosion resistance for optimum performance within high pressure applications. FRP is lightweight, extremely strong, easy to install, and resistant to deterioration.

※Corrosion resistance, light weight; long lifespan; no need for anti-corrosion treatment on the inner and outer wall; the weight is only1/4 of the steel pipe and 1/8 of the concrete pipeline; low transportation cost; low requirements for lifting equipment.

※The pipe can be of any length

※Joint form

Special sleeve connection for rubber fiberglass composite.

※Smooth inner wall

Low head loss: low pumping energy consumption and low operating cost minimize attachments and make it easy to clean.

※Good sealing performance

Adopt rubber ring seal; highly sealed sleeve type joints ensure no leakage; easy installation, short installation time; can adapt to small direction changes or foundation settlement without pipe fittings.

※Manufactured according to multiple standards

GRAD pipe produced by the advanced technology of filament winding process can be manufactured according to GB, ASTM, BS, DIN, ISO and other standards.

※Stable performance

Continuous winding is due to the combination of technology and equipment, and the main raw materials such as resin, curing agent, chopped glass fiber, and quartz sand are accurately metered and automatically supplied by the servo system, thereby minimizing the impact of human factors during the production process. The winding process is implemented strictly in accordance with the process sheet, and the performance dispersion of the final product is very small, and the quality is very stable.

※High axial and ring strength

Due to the different design of the pipeline layup process, the continuous winding has chopped fibers distributed between the layers of the winding, and the chopped fibers are interspersed and distributed in the circumferential winding fiber layer and the resin interlayer, forming an approximate 3D weave distribution. The bonding strength is greatly improved, and the axial and ring strength are high.

※High efficiency, low raw material loss

The steel belt continuous moulding method is adopted. The liner, inner structure layer, sand layer and outer structure layer are formed at one time, and they are heated and cured by the heating device at the back of the mould, and the mould is automatically demoulded. Materials such as resin, chopped fiber, quartz sand, etc., all adopt servo precise automatic feeding system, which makes high production speed and high efficiency. And the raw material consumption is accurately controlled to minimize waste.

About Us

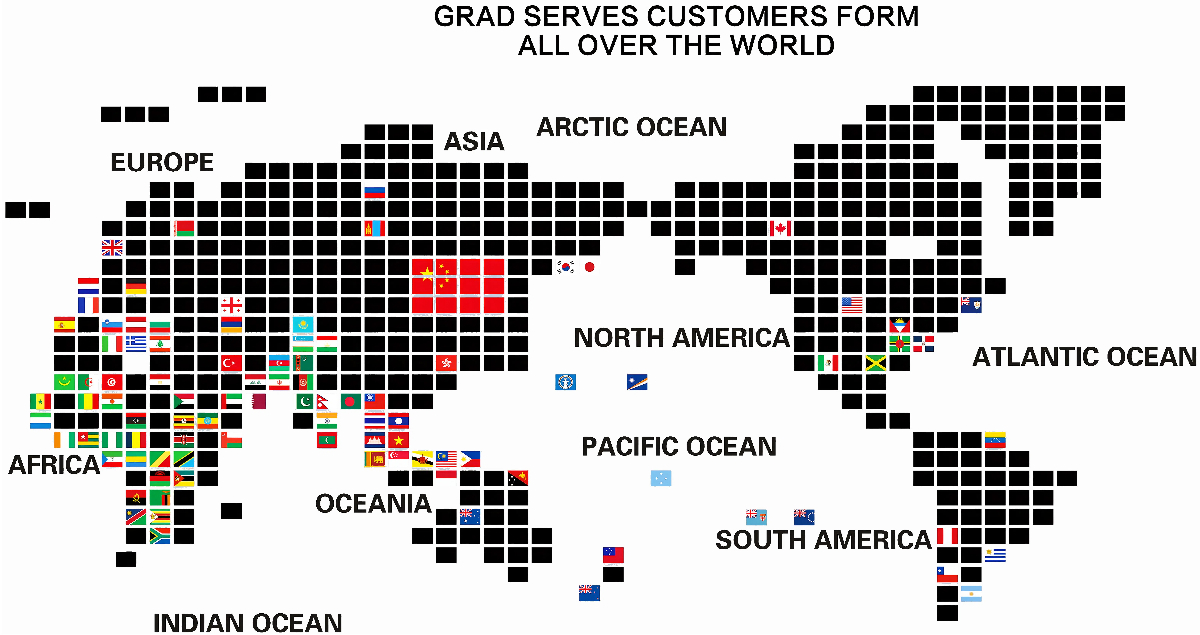

GRAD sales network covers over 100 countries and regions like America, Australia Indonesia, Malaysia, UAE, Thailand, Nigeria etc and has established branch company in USA, and set up offices in Cambodia and Thailand to make overall layout of global market.

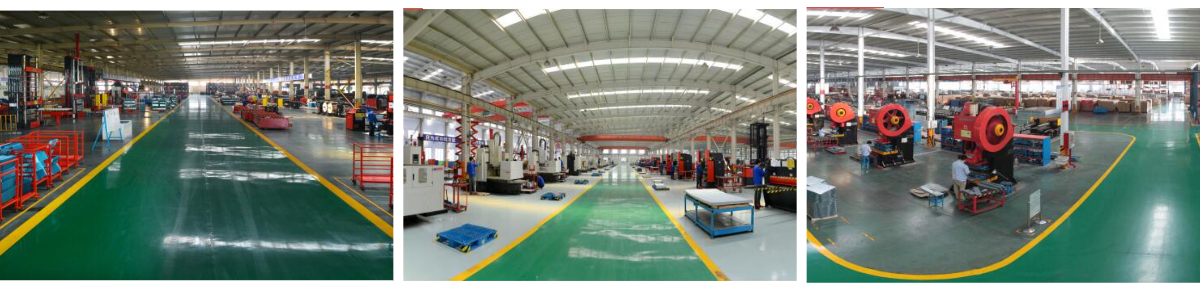

Shandong GRAD Group is a large modern enterprise with over two decades history. Our business started in 1993, with staff of over 2200, we are focus on R&D, production, marketing, installation and maintenance for central air conditioning system and G R P composite material products. We are committed to providing customers with one-stop central air-conditioning and FRP composite material product solutions.

For central air conditioning products, we have production facility covering 450000 sqm, we can offer products for the whole system including chillers, heat pumps, cooling towers, A H U s, F C U s and ventilation products. To better participate international project, we have C T I, C E, A H R I certificates to guarantee our products quality.

For G R P composite material products, we have production facility covering 700000 sqm. With its feature of light weight, high strength, anti-corrosion and long service life, the G R P products are ideal replacement for steel products. We can offer process like vacuum injection, G R P winding, S M C mould pressing, molding pultrusion and hand paste. Based on different process, we can offer clients customized products.

GRAD international business starts in 2009, now its products have been exported to 100 countries and regions.

GRAD, as a flagship enterprise in central air conditioner and G R P composite material products industry, is dedicated to be a one-stop supplier for global purchasing agents.

FAQ

Q1. Where is your loading port?

A: Qingdao/Shanghai/Tianjin, China or else port as for your request.

Q2. What's your company's main products?

A: Our company is specialized in central air-conditioning,ventilation and GRP Composite material products.

Q3. What’s your payment term.

A:T/T,30% deposit,70% before delivery or 100% Irrevocable L/C at sight.

Q4. What’s your Warranty.

A:Warranty for 12 months from the date of shipment from the factory.